recycled powder

Why to think additively

Freer, faster,

cheaper

Additive manufacturing requires that we change the input data, not the entire process. This means you can reduce delivery times from weeks to mere days, and you avoid paying for extra molds, tools and materials.

Conquer both convention and

competition

Ship propellers, car headlights, cranial orthoses or fuel tanks of a rocket. Anything you can imagine and design in CAD software can be made lighter, more durable

and with improved properties.

Nature will be

proud of you

Together we will create intricate shapes inspired by nature’s design. That will enable us to produce up to 80% less waste and considerably shorten supply chains.

Additive Manufacturing

Want to quickly test your idea in practice? We will produce a prototype that will be indistinguishable from the final product within a few days.

- We choose the ideal technology and material.

- We verify the accuracy of production data.

- We will perform appropriate post-processing.

We will create even the most complex objects for you out of plastic and metal. Just give us your design. Precise post-processing is a matter of course.

- Production of individual pieces and entire series without unnecessary waste.

- Savings on cutting tools, molds and materials.

- Quick iterations and easy design changes at any moment.

Additive know-how

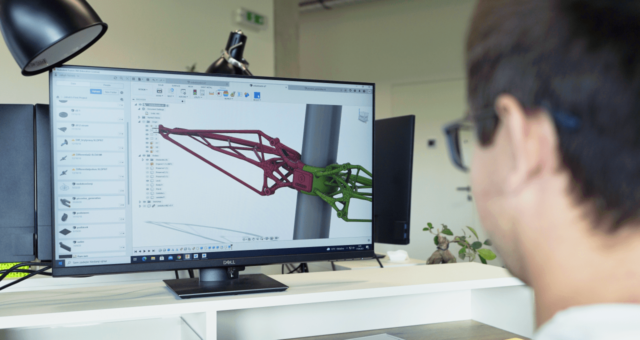

Don't think about how your idea will materialize, but how meaningful it will be. Billions of years of nature's advanced architecture and artificial intelligence will help you with the design.

- Create designs that are sustainable and as free as your idea.

- Inspired by natural structures, you increase quality, reduce weight and combine function and design.

- AI models hundreds of possible solutions for you and you choose the best ones for the application.

Decompose matter into ones and zeros and create a full-scale digital model for you with the Atos 5 high-end optical scanner.

- We reveal the geometry and structure of known and unknown objects.

- We enable the production of parts that lack design data.

- We verify dimensional accuracy and tolerances before starting mass production.

We discover the connections between structure and material properties. In our laboratory, we test, develop and combine conventional technology with additive technology.

- We test hardness, tension, compression and bending of plastic and metal parts.

- We have all the equipment for surface and internal structure analysis.

- We enable controlled innovation development, including expert consultation.

Starting with additive technologies is like discovering a time machine without a manual. We can help you not only understand its potential, but also apply the knowledge in practice.

- We organize intensive workshops including comfortable accommodations, gastronomic specialties and evening programs.

- We consult on your design proposals, projects or current technological challenges.

- We advise on additive manufacturing, the latest technologies and materials.

Conventional know-how

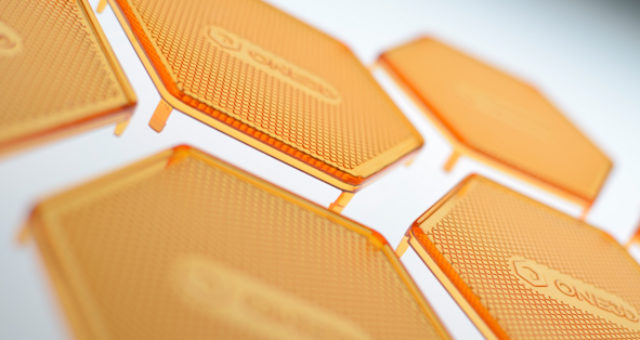

Optical components with precisely defined optical properties. Integrable into a wide range of optical systems.

Zjistit více

Production of durable and precise polyurethane components with excellent mechanical properties.

Zjistit více

Precision parts processing with high repeatability and minimum tolerances. With modern equipment and cutting-edge technology, we realize even the most demanding projects with maximum efficiency and quality.

Zjistit víceWe are additive

We continually add more. Plastic, metal, the most recent technologies

and a personal approach. Whenever we work together.

Společně tvoříme

nová konstrukční pravidla

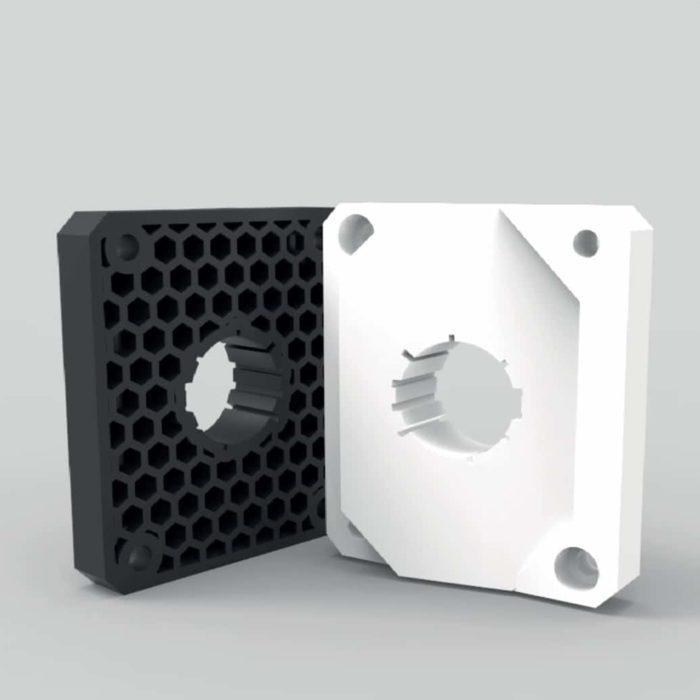

Costs half, weighs a tenth

Using the honeycomb structure and the additive technology SLS, we have reduced the cost of the mounting blocks and eased the work of the press operators.

Zjistit více

Artistic tribute consisting of algorithm, stainless steel and garnets

We helped the experimental goldsmith Zdeněk Vacek win at the Designblok 21 festival and pay tribute to his mother’s lifetime work.

Zjistit více

Details are important

We produced detailed 1:400 scale models of buildings, including spacious parking lots, trees and even the smallest details.

Zjistit víceCo o nás říkají zákazníci

Additive manufacturing

Selective Laser Sintering (SLS)

The most widely used method of industrial 3D printing, during which powder is sintered by a powerful laser. Ideal for prototyping and production parts.

Zjistit víceMulti Jet Fusion (MJF)

HP's powder sintering technology with reagent under infralamp. The high production speed makes it suitable for mass production.

Zjistit víceUsed materials

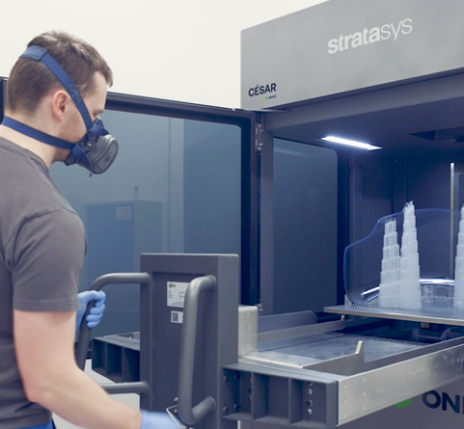

Stereolithography (SLA)

The oldest technology for laser curing of liquid photopolymer. Suitable for prototyping applications where a high level of detail and fine surface finish are important.

Zjistit víceUsed materials

Direct Metal Laser Sintering (DMLS)

The metal parts are created by successive layering of powder, which is again melted by the laser. A technology suitable for fast production of complex shapes.

Zjistit víceUsed materials

When it comes to surfaces

we are not superficial

Do you want a rough matt, maximum transparency or a metallic look? Choose the right finish for your part.