Key features

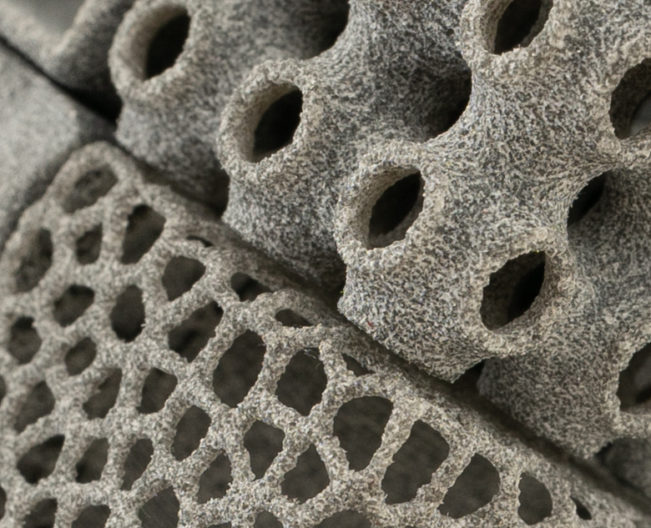

The basis of this material is PA12 with the addition of glass particles, which make up 30% of the powder content. Thanks to this the material has a high rigidity and density.

PA3200GF is wear-resistant, machines well and has long-term stable properties.

In addition, during the manufacturing process, the material is stable and there is little thermal deformation.

Suitable uses

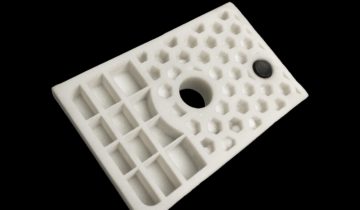

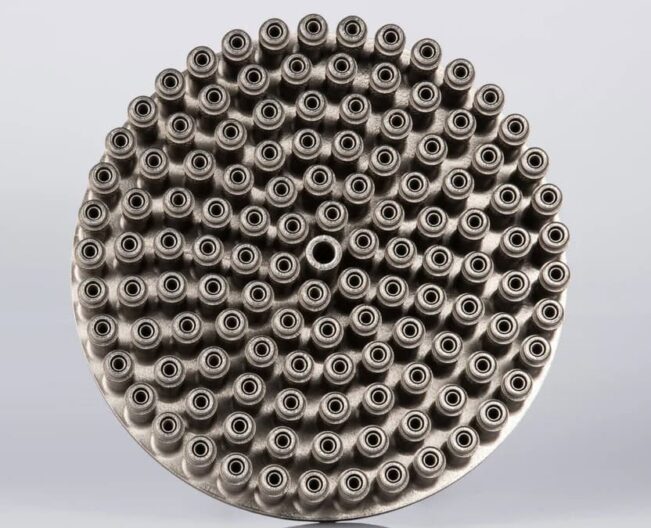

This polyamide is most commonly used in functional prototypes that are subject

to static loads or require rigidity and abrasion resistance, while the PA3200GF can be combined with additional machining to produce high-precision final parts.

Specific applications

- gearing

- clamping elements and lasts

- engine radiator chambers

Technological specifications

| Standard delivery time | 5 working days |

| Production accuracy | ±0.2% (with lower limit ±0.2 mm) |

| Production layer | 0.12 mm |

| Minimum wall thickness | 0.5 mm (preserving properties 1 mm) |

Datasheet

| Tensile strength | 51 MPa |

| Modulus of elasticity | 3200 MPa |

| Elongation | 9 |

| Heat distortion temperature HDT 1.8 MPa | 96 °C |

| Heat distortion temperature HDT 0.45 MPa | 157 °C |

Download datasheet

Keep everything in one place. Download the datasheet of all our production materials.

Download datasheet