What if your parts worked as well as they looked?

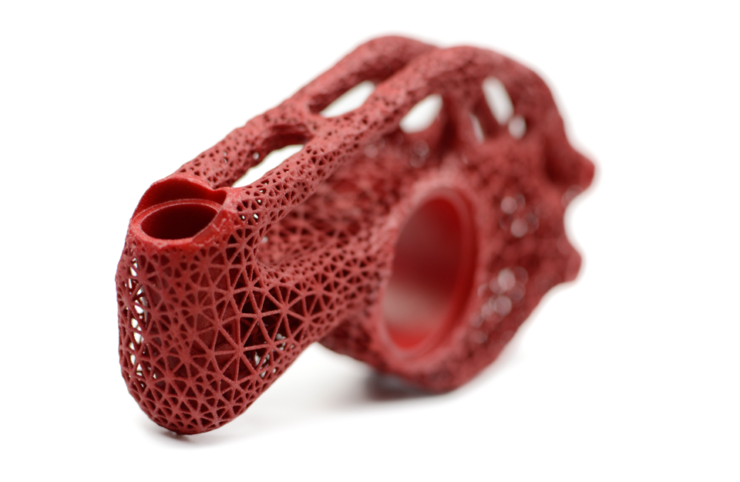

Biomimetic design inspired by nature? Use the leaf structure of a tree or the lightness of a bird’s bone in your design. Design parts knowing that additive technology will allow you to achieve the maximum potential of your innovations.

I. Analysis

How can you ensure the highest possible quality? Will the result be cost-effective? Do we know the boundary conditions, requirements, preferences? Before we start designing a new part, we need to make sure it makes sense.

II. Design

After the analysis, we have all the necessary input information.

Nothing prevents us from starting with the structural design.

From the initial concept through optimization and visualization to the final form of the part.

III. Production

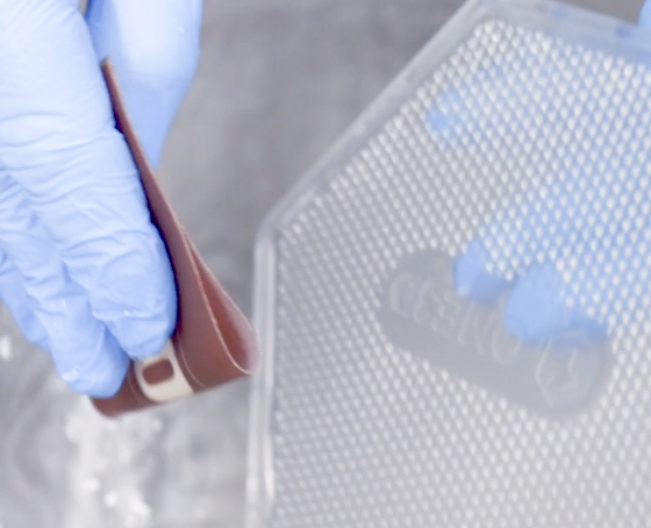

We set the orientation of the part, choose a support system and the part starts to grow layer by layer in front of our eyes. All we have to do is finish the part. Will you choose chemical smoothing, plating, painting or dyeing? There are no limits.

3-step analysis you won't go wrong with

1. Determine the suitability of a part

Shape complexity, number of pieces to produce, degree of added value, part size, or type of load: there can be many input parameters of a part, and they should not be underestimated. Together, we will identify parts in your portfolio that will clearly benefit from additive manufacturing. You can also manage the identification yourself. You can acquire the necessary skills in our workshop.

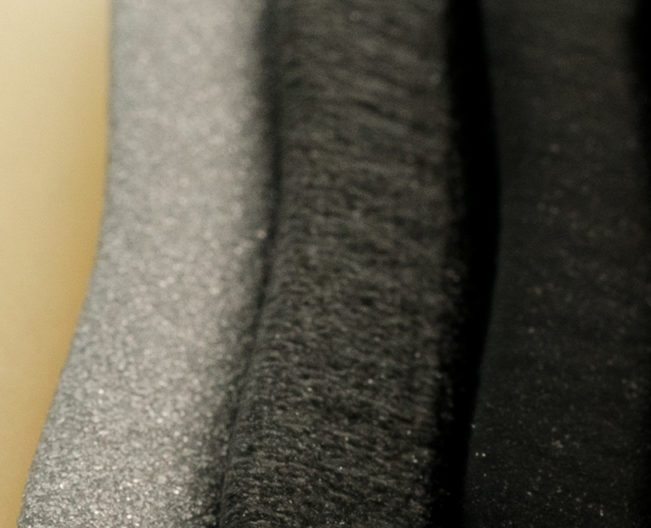

2. Material and technology selection

You can make the same part from different materials and with the help of different technologies. How to choose the ideal material and technology? At this stage, we take into account the demands on functionality and appearance, and then we recommend the appropriate combination of material and technology, including the ideal post-processing for optimal results.

Choosing an approach to design

Do you have a part selected? Do you know and from what you want to make it? Great! Now come the questions about its design. You can choose from 3 options: not optimize the shape of the part, partially modify the design or proceed with a complete redesign. Each approach has its pros and cons. We will not only help you make the right choice, we will lend you our designers so you can create a design together.

What can be used in AM design?

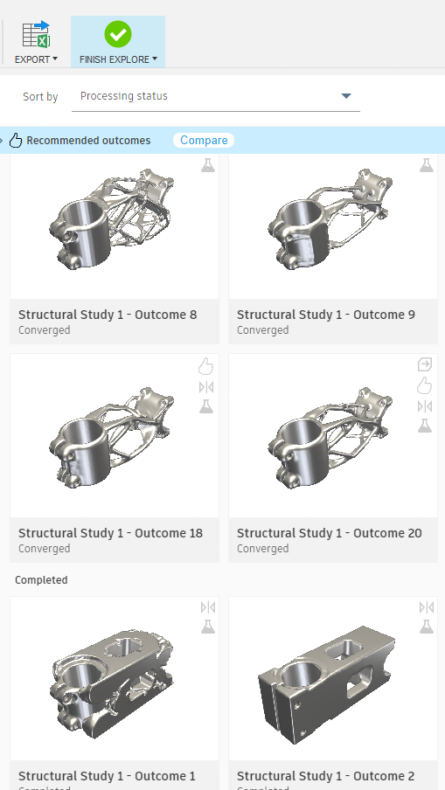

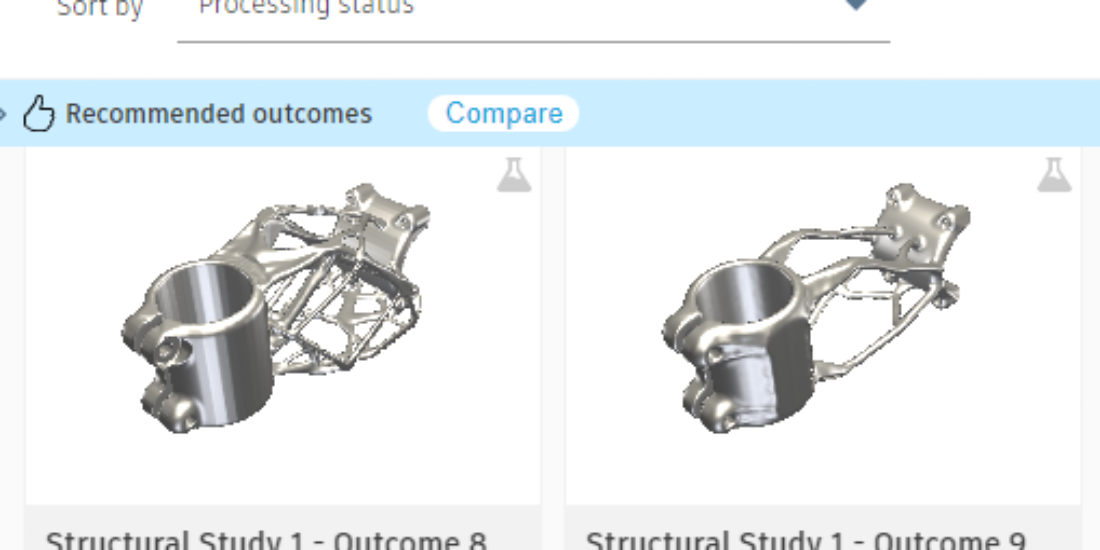

Topological optimization and generative design

Do you need to create a functional part and meet stress conditions, but are unable to reduce weight? With the appropriate software for topological optimization and generative design, we can help you achieve the ideal ratio of rigidity to weight of the part.

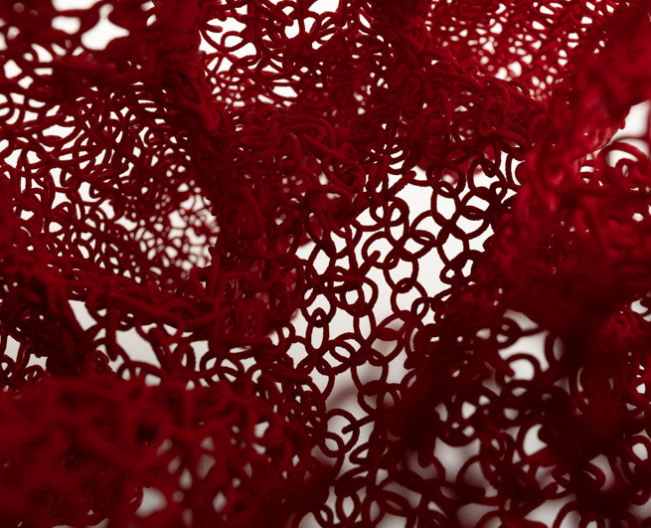

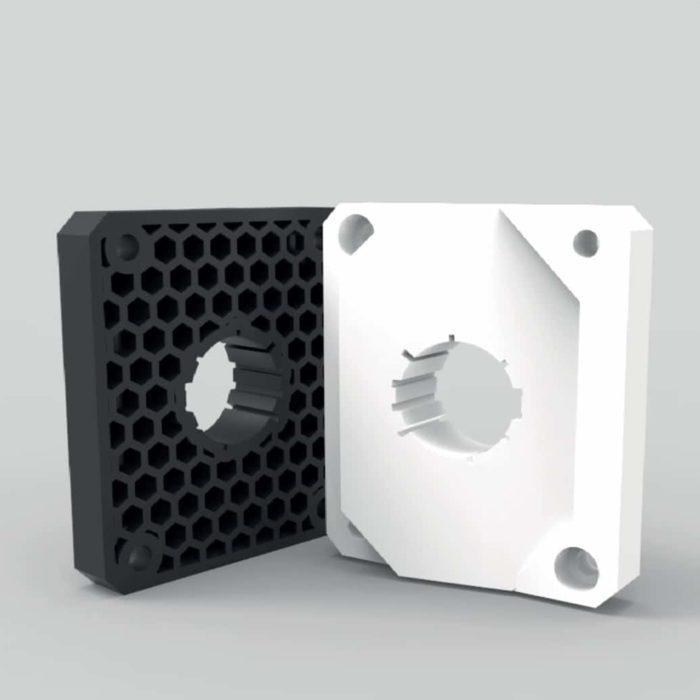

Spatial and surface structures

From honeycomb to truss structures to complex surface geometry. Using periodically repeating elements, patterns or surfaces, you can easily lighten a solid part while maintaining or improving its properties, whether mechanical or thermal.

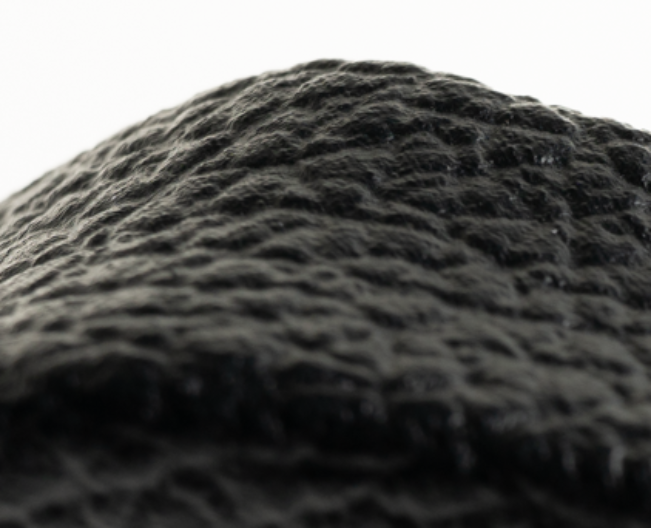

Digital textures

Textures not only give the piece a unique look, but can also perform a functional role, reducing slip, improving grip, aerodynamics or light scattering. They can even mimic completely different materials such as leather, wood or stone.

Gloss, matt and color to your liking

The manufactured part is born. To ensure the final part is exactly to your liking, next comes post-processing, i.e. surface treatment. Abrasive blasting, machining or chemical smoothing. And finally? Painting, coating or plating. Once it is done, you just need to check the quality and send it. The part is now ready to fulfill its mission in life.

Společně tvoříme

nová konstrukční pravidla

Costs half, weighs a tenth

Using the honeycomb structure and the additive technology SLS, we have reduced the cost of the mounting blocks and eased the work of the press operators.

Zjistit více

Artistic tribute consisting of algorithm, stainless steel and garnets

We helped the experimental goldsmith Zdeněk Vacek win at the Designblok 21 festival and pay tribute to his mother’s lifetime work.

Zjistit více

Details are important

We produced detailed 1:400 scale models of buildings, including spacious parking lots, trees and even the smallest details.

Zjistit více