Challenge :

Produce 3 art objects within 5 days.

Solution:

A contour face mask and two life-size hands with the forefinger and thumb touching

as if pinching, all stainless steel, giving the subjects a detailed and highly luxurious look.

Impact:

for the client: The possibility of unlimited realization of the creative intent.

Artifacts have been created that cannot otherwise be produced in any normal way.

for us: Designing and testing a new type of support that is easy to remove.

for both parties: A completely atypical commission and a unique experience

where machinists and goldsmiths create art together.

Result:

Timely delivery of artifacts made of metal and Zdeněk Vacek’s victory in the category

of the best installation at the prestigious Designblok 21 competition, and of course

the indescribable pride and emotion of his mother Jitka.

Service: End-product manufacturing

Materials: 316L stainless steel, Waterclear

Technology: Direct Metal Laser Sintering (DMLS), Stereolithography (SLA)

Post-processing: Support removal, Sanding and surface smoothing

2 weeks to the start of the exhibition: Zdeněk comes with a vision and a story

He decided to express his respect and love for the woman who gave him life, in his own way. Zdeněk Vacek, winner of the Czech Grand Design for the best jewelry, did not buy a flower or chocolate. Instead, he came to us with a very unusual, but quite clear idea. He wanted to make his mother’s face and hands from stainless steel on a 1:1 scale and decorate them with Czech garnets.

“I like my work to mirror handicraft and contemporary technologies at the same time. In the project

Jitka-PUK-3D-UPM, my wish was to capture

the features of my mother Jitka in a futuristic and yet faithful way while she works on PUK (microspot welding for fixing precious stones) and to pay tribute to her for the 8 years she has been decorating jewelry with this method. This is a very immersive, painful method of jewelry art which demands a great deal

of patience. Jitka’s face and hands symbolize for me the places where the demands of her work and her mother’s mission and virtues are most reflected.

Face and hands under scanner: Optical digitization of the maternal essence

We collaborated on the project with colleagues from 3Dees Industries, who arranged

for Zdeněk to scan his mother Jitka using the ATOS Q 3D optical scanner from Carl Zeiss GOM Metrology.

This data then served as the basis for algorithmic modeling in Grasshopper, in which Zdeněk created a digital model for printing.

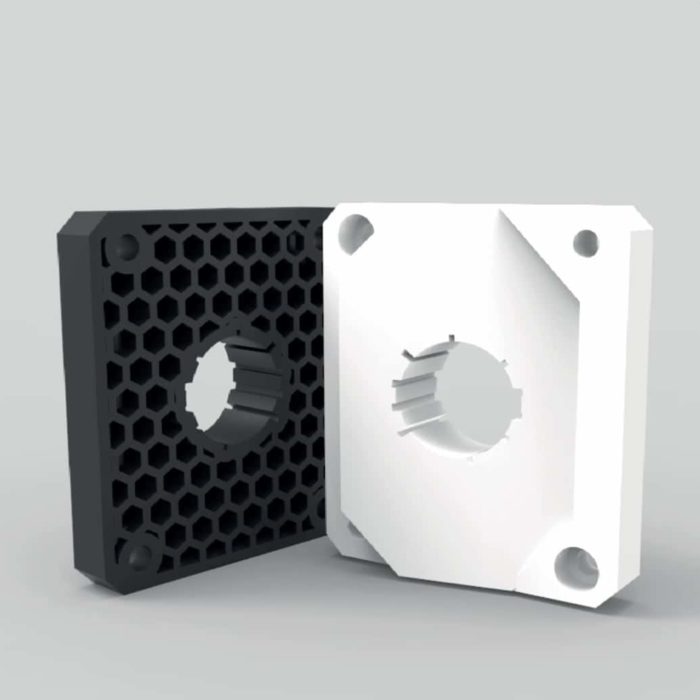

Even before production, we (with regard to the chosen material 316L) optimally oriented

the mask and hands at ONE3D and used a unique support system for them. These supports had to not only support each complex part with their shape, placement and structure,

but also be easily removed from it during manual post-processing, all with zero impact

on the extremely important and delicate aspect of the entire work – its visual aspect.

We have 5 days: How and from what will we produce the pieces?

The exhibition itself was still 14 days away, but we had to complete all the preparation

and production within one working week. Production was by no means the last step towards the final presentation of the parts. After production, it was still necessary to arrange for transport, manual post-processing, PUK microwelding of Czech garnets and the actual installation in the exhibition space at the Museum of Decorative Arts. Fortunately, all this was already taken care of by the skilled goldsmiths from Zdeněk Vacek’s team.

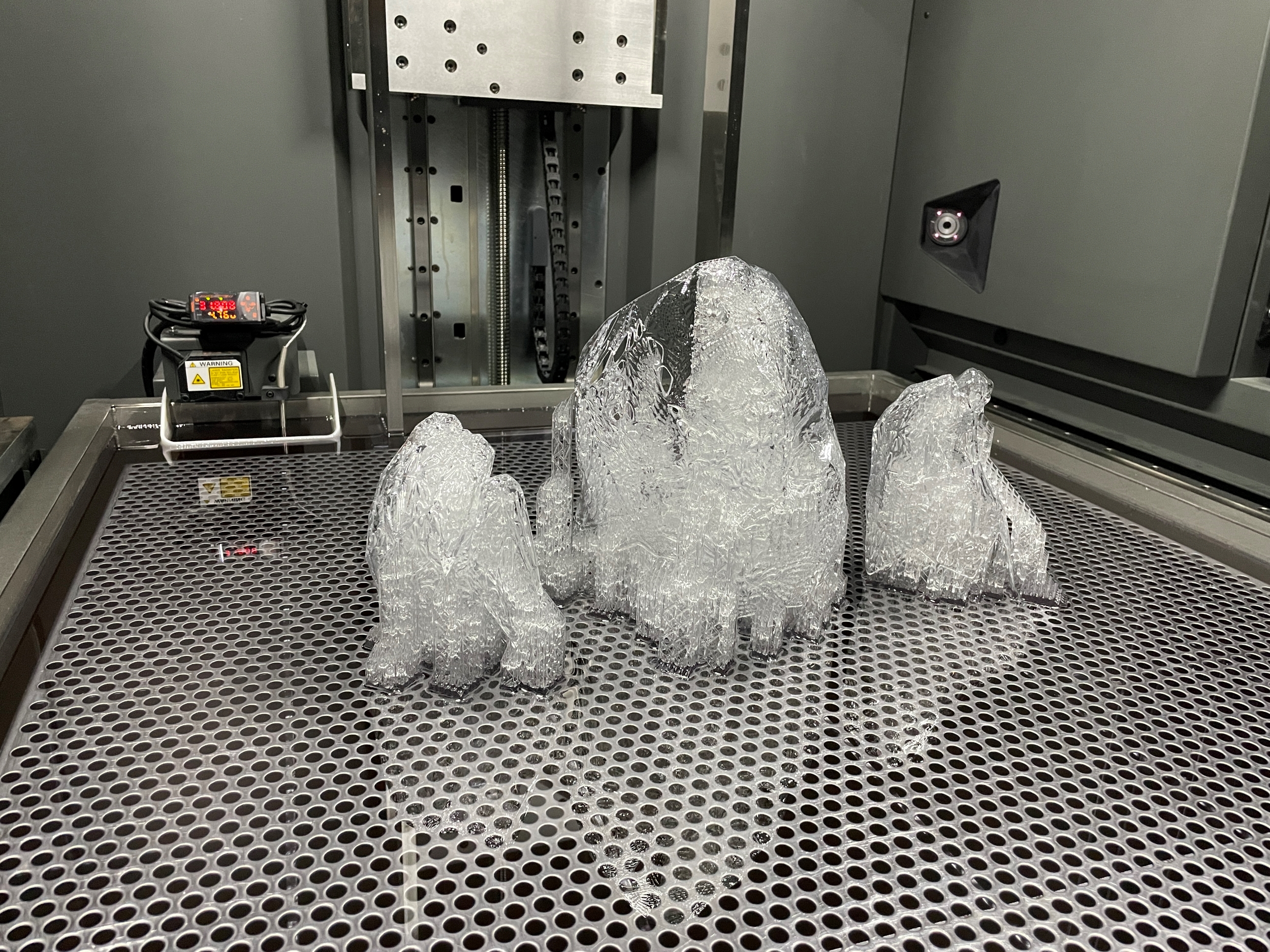

“Due to the critical time pressure

and the insurmountable deadline,

we also made parts from photopolymer

in parallel to have a backup variant.”

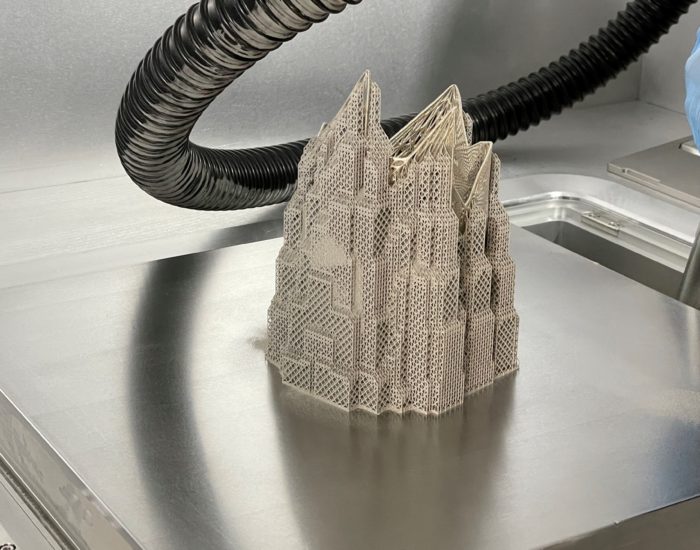

The mask and hands were made of both 316L stainless steel using DMLS technology

as well as Waterclear photopolymer using SLA technology.

So how much respect can one have for a woman, and how long does it take to create it?

The correct answer: Immeasurable and a lifetime.

Nevertheless, the one we created at ONE3D had the following parameters:

Mask and hands including photopolymer supports:

- sum of the volumes of the parts: 157 cm3

- production time: 24 hours

Mask and hands including stainless steel supports:

- sum of the volumes of the parts: 207 cm3

- production time: 28 hours

The production from metal went quite smoothly in the end, and considering how good

the plastic parts looked, Zdeněk decided to use a combination of both versions for his installation at Designblok.

Stainless steel, polymer, video, copper:

Jury: just look at that!

Zdeněk Vacek is well aware that the object of modern art is not only the art object itself,

but also its arrangement, which is why he took great care in every detail of his installation.

For example, the information board that contains facts about his mother’s level

of commitment (how much patience and how many fingernails and hours of difficult work

it cost her) aren’t too far from Voyager’s Golden Records.

All the information here is precisely etched into the copper plate. You can compare

its accompanying avant-garde video to the video above from our production.

You will see that although both are about capturing the same process, the approaches

of the artist and the industrial company are quite different, to put it mildly.

No wonder, then, that Zdeněk Vacek easily won the prize for the best installation

of the exhibition from the jury. And we are glad that we were there.

Mixing the world of technology and art was indeed an uplifting experience for us.

Special thanks to Václav Jirásek, who brought us great memories thanks to perfect photos.