Key features

This aluminum alloy, which belongs to a narrower group of silumins, is characterized mainly by high thermal and electrical conductivity, low density, high corrosion resistance and good mechanical properties, and its properties can be greatly influenced

by the heat treatment of this material.

Suitable uses

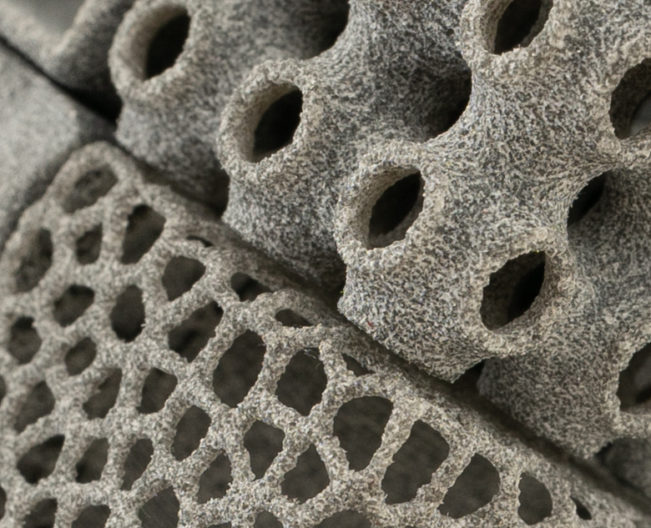

A good ratio between mechanical properties and density make AlSi10Mg a suitable choice for a large number of engineering applications in aerospace and automotive. Due to its high thermal conductivity, it is used, for example, for the production of heat sinks and heat exchangers. This material is also a suitable alternative for the rapid production of aluminum castings.

Specific applications

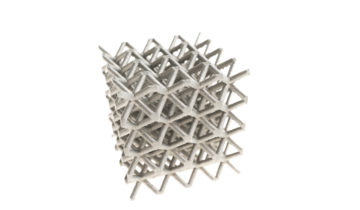

- topologically optimized bracket for aerospace industry

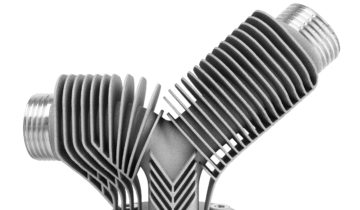

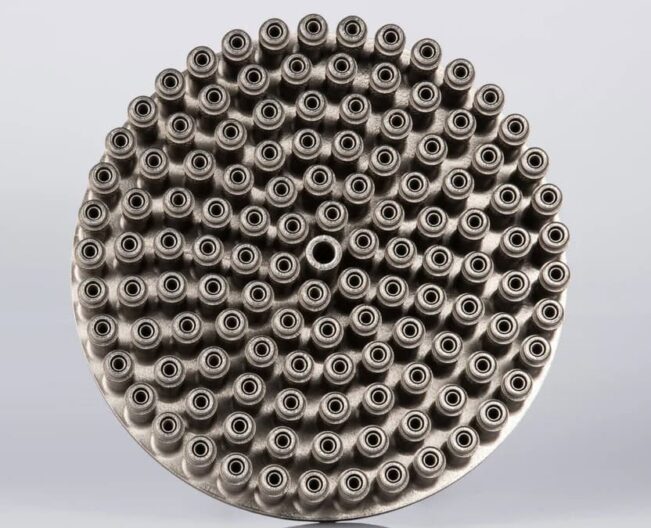

- heat exchanger for energy industry

- prototype of electric motor chassis with cooling

Technological specifications

| Standard delivery time | 10 days |

| Layer height | 0.03 – 0.08 mm |

| Minimum wall thickness | 1 mm |

| Maximum part dimensions | 390 x 390 x 390 mm |

Datasheet

| Layer Height (μm) | 30 | 80 | ||

| Condition | No Heat Treatment | No Heat Treatment | Dissolution Annealing | |

| Orientation | XY | Z | ||

| Tensile strength Rm (MPa) | 410 | 440 | 370 | 310 |

| Contractual Yield Strength Rp0.2 (MPa) | 265 | 240 | 230 | 220 |

| Elongation at break ε (%) | 6 | 4 | 2.5 | 6 |

| Density ρ (kg/m3) | 2650 | |||

Download datasheet

Keep everything in one place. Download the datasheet of all our production materials.

Download datasheet