Who we are

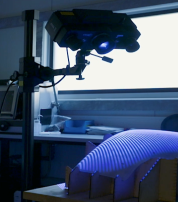

ONE3D is shaping the future of products.

As a leader in advanced manufacturing

and technological development, we integrate additive manufacturing, advanced materials, and engineering innovations.

Our mission is to enable companies

to innovate faster and create products

that push the boundaries of modern production.

Where we are heading

Vision

We push the boundaries

of manufacturing. Our vision is

to be the driving force of advanced manufacturing and technological development, transforming the way the world creates new products.

Mission

Enable companies to innovate faster and more efficiently through the integration of additive manufacturing, smart materials,

and engineering innovations.

Our goal is to reshape current manufacturing standards and enable the creation of products that surpass the limits of traditional production.

Goals

Strengthen ONE3D’sposition as a key player in development and hybrid manufacturing across continents.

Our ambition is not only

to lead technologically,

but to become synonymous with the ability to deliver real, measurable value.

Establish a comprehensive

and efficient process

that seamlessly transforms customer requirements

into final products.

Foster a positive environment

that nurtures collaboration, innovation, and creativity,

while shaping a strong company culture built on shared values

and open communication.

What we've been through

Co o nás říkají zákazníci

recycled powder

11 důvodů proč spolupracovat s ONE3D

We have ISO for Additive Manufacturing

We protect quality, employees and nature. Read more about our standards in our blog article.

Protecting quality

for customers

Protecting Nature

Protecting employees

Don't miss the additive news

Once every 3 months, up-to-date articles, new case studies and industry news.

Subscribe!