Benefit from

the combination of Additive Manufacturing

and CNC machining

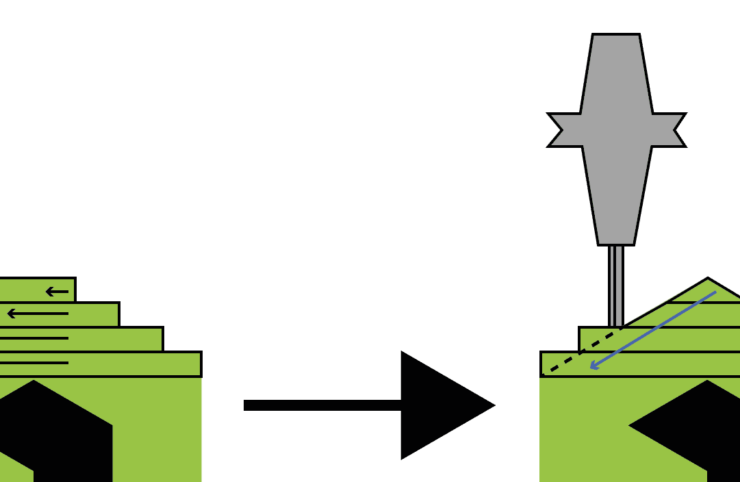

The hybrid advantage is the combination

of additive manufacturing and subtractive

processes such as milling.

Hybrid manufacturing processes are fundamentally

on the same machine, but it is possible to combine

several production facilities together.

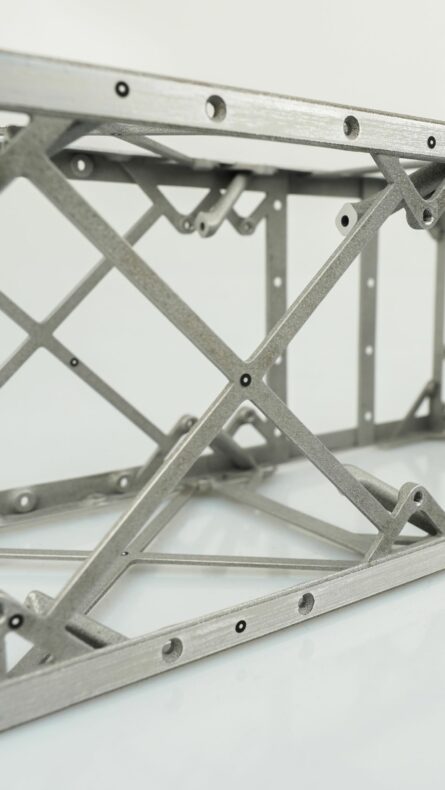

Design freedom

Create complex geometries,

that would be difficult

or impossible to produce using conventional manufacturing methods alone. Use hybrid manufacturing to design lightweight structures, higher performance components

and innovate product designs.

High precision

With hybrid production,

almost every surface can

be printed and machined

in the same reference

coordinate system,

allowing tighter tolerances.

Cost efficiency

During the production process

material is added to the parts

only where it is needed.

Excess material (powder)

can be recycled and reused.

This makes it possible to keep costs as low as possible.

The best of both worlds

Additive Manufacturing

+ Material saving

+ Design freedom

+ Available materials

+ Complex parts production

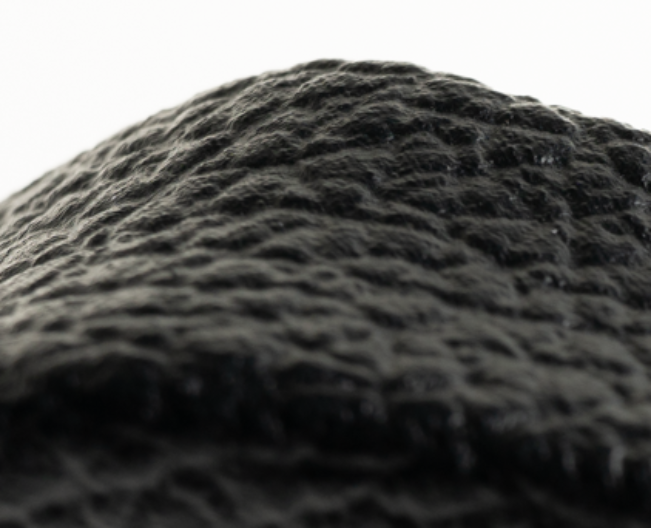

– Lower production precision

– Lower surface quality

CNC milling

+ Repeatable

+ Accurate

+ Good surface quality

+ High productivity

– High material waste

– Higher costs for piece production

Hybrid manufacturing

Combining the advantages of CNC milling and Additive technologies.

The result are high-performance parts with engineering precision.

Main advantages

+ Engineering precision for complex parts

+ Versatility

+ Personalisation options

+ Guaranteed assemblability of parts in engineering assemblies

The part's journey from design

to shipping

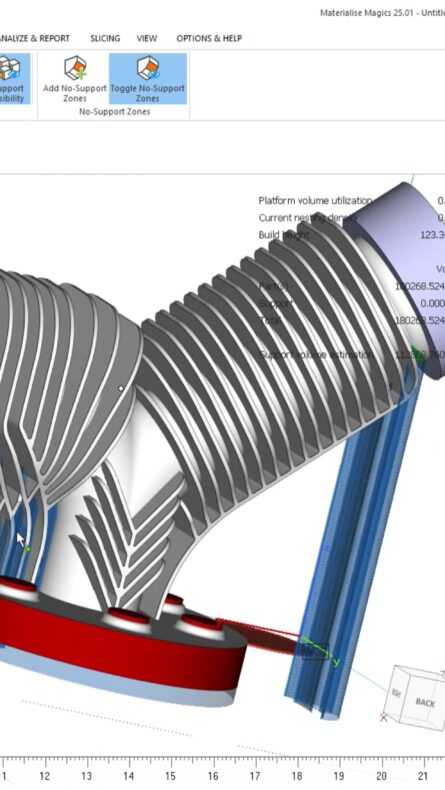

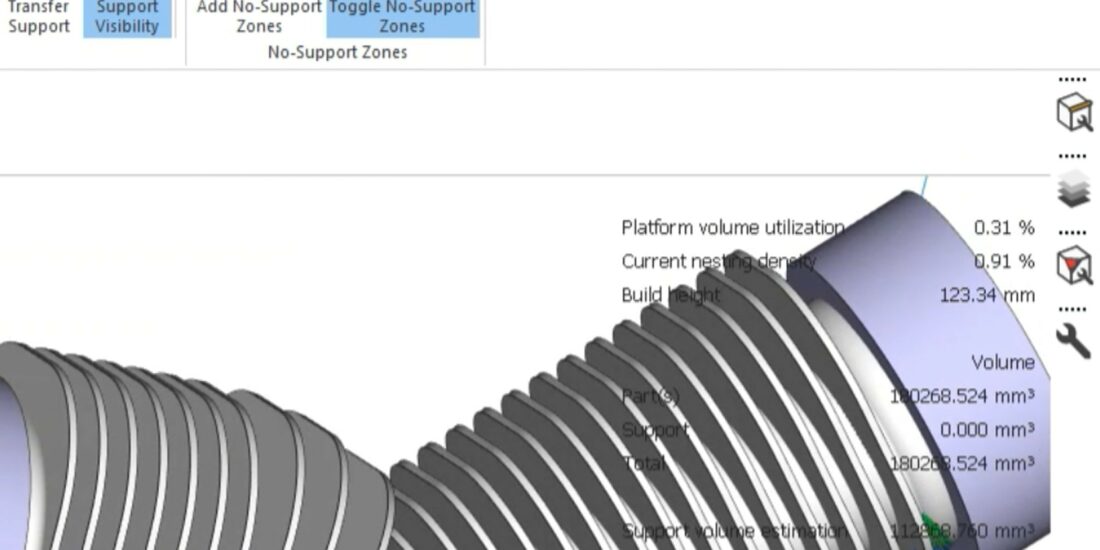

Product design

Using advanced 3D design software, we will create

a CAD model of your part.

We will perform the necessary tests and simulations

to ensure the required properties.

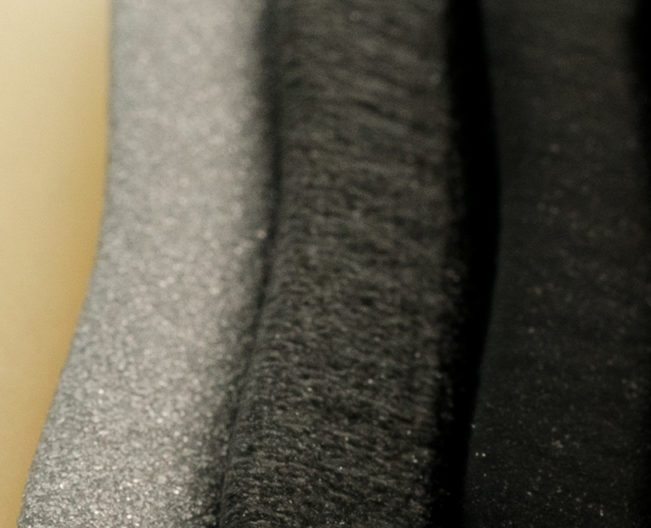

Production by Additive technologies

Then we select the ideal material and set the appropriate printing process parameters.

We achieve production accuracy as specified by ISO 2768.

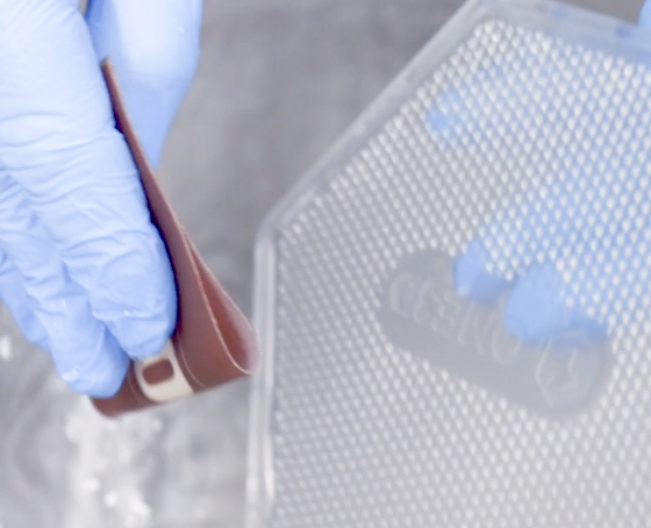

Post-processing

After printing and cleaning the parts from the production powder, CNC machining comes next. We machine touch surfaces, threads, holes, and more to machine precision.

Shipping to the customer

Once all production and post-production

operations are completed, the finished product

is ready to be sent to the customer and applied.

Společně tvoříme

nová konstrukční pravidla

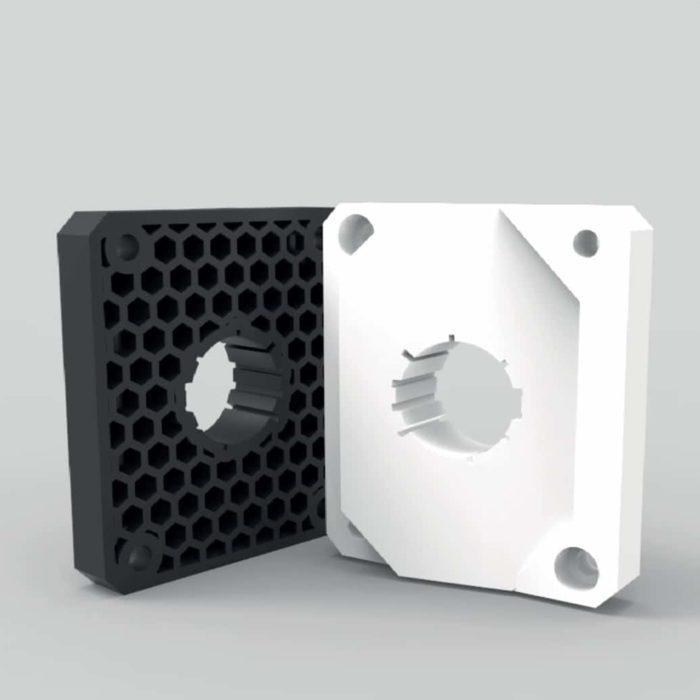

Costs half, weighs a tenth

Using the honeycomb structure and the additive technology SLS, we have reduced the cost of the mounting blocks and eased the work of the press operators.

Zjistit více

Artistic tribute consisting of algorithm, stainless steel and garnets

We helped the experimental goldsmith Zdeněk Vacek win at the Designblok 21 festival and pay tribute to his mother’s lifetime work.

Zjistit více

Details are important

We produced detailed 1:400 scale models of buildings, including spacious parking lots, trees and even the smallest details.

Zjistit více