About additive manufacturing

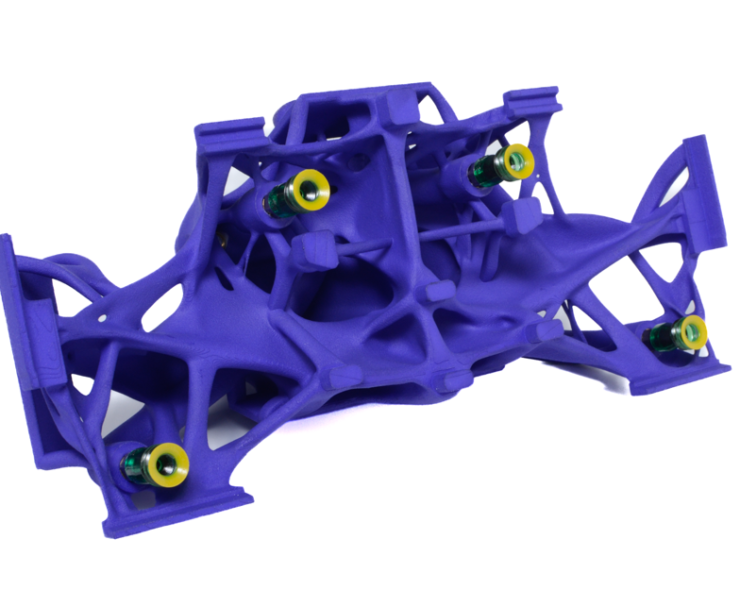

Additive Manufacturing (AM) refers to industrial 3D printing. During this manufacturing process, three-dimensional objects are created according to a digital model, layer by layer. High-power lasers are most commonly used for this purpose, melting and curing powdered material from plastic or metal. Additive manufacturing allows objects to acquire unique properties that are unattainable in conventional ways.

Key Benefits of

Additive Manufacturing (AM)

Freedom of design

Designers can design virtually any design without cost implications, as changing the design’s shape complexity does not have nearly as much impact on price for AM as for conventional manufacturing.

Speed of delivery

Delivery of parts within a few days including post-processing, even in a series of hundreds or thousands of pieces. Due to the speed and flexibility of AM, complex parts can be produced practically the next day.

Cost reduction

You will avoid fixed costs for molds, tools, piece or small batch production. For example, a lighter jig will allow the robot to move faster, thus increasing productivity and reducing the price per piece produced.

Personalization of parts

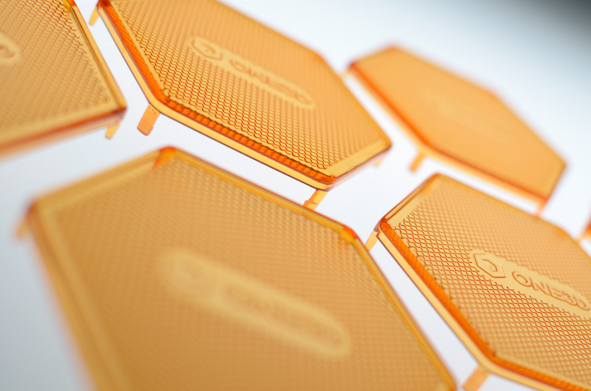

AM allows direct part marking or completely individual design of each product, saving post-production costs, naturally increasing brand reach and shifting customer perception of product value.

Multiple parts = 1 piece

Multi-part assemblies manufactured conventionally can be replaced with a single part using AM, eliminating the need for completion or assembly while maintaining all necessary functions.

Sustainable technology

In additive manufacturing, the material is not removed, but added, so only the necessary amount of powder is always used. This creates a minimum of waste and eliminates the costs associated with its recycling.

Tips for using additive manufacturing

Be inspired by cells and plug in chips

Ask yourself, how would nature itself create this part? With an organic shape, lightweight internal structure and always an optimal use of material. With the help of algorithms, we can generate many such designs and select the most (r)evolutionary design.

Change tactics according to the situation

We can modify the parameters of your part at any time during its creation. Just adjust the boundary conditions. You do not need to produce new molds or wait for the machines to be reconfigured.

Discover and innovate

Whether you know exactly what you want to make or just need to figure it out, we’ve got you covered with additive manufacturing and additive know-how.

Hit the target

Together we select the right mix of state-of-the-art technology, materials and post-processing to produce exactly the prototypes or end parts you need.