What is it?

Spray painting involves applying liquid fillers, bases, paints or varnishes using a paint gun to the surface of the part. Before applying the coating, the part must be thoroughly cleaned and degreased in order to achieve perfect adhesion to the base surface.

After applying the coating, the resulting layer must be allowed to dry perfectly,

so-called hardening.

Sufficient ventilation and baking time of the parts at an elevated temperature helps this. Wet coating technology can be used to spray surfaces in the order of tenths

to hundredths of a millimeter.

What is it used for?

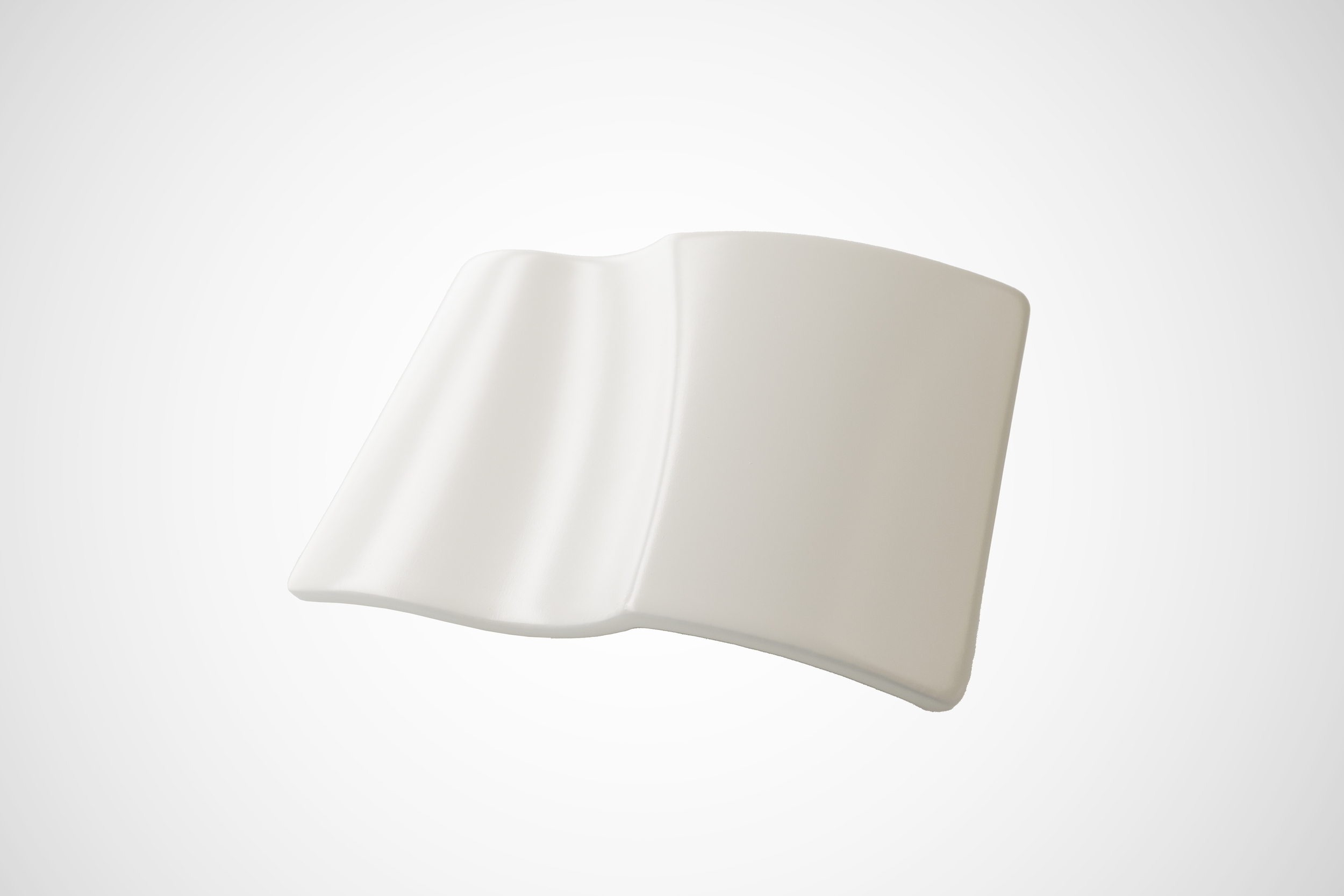

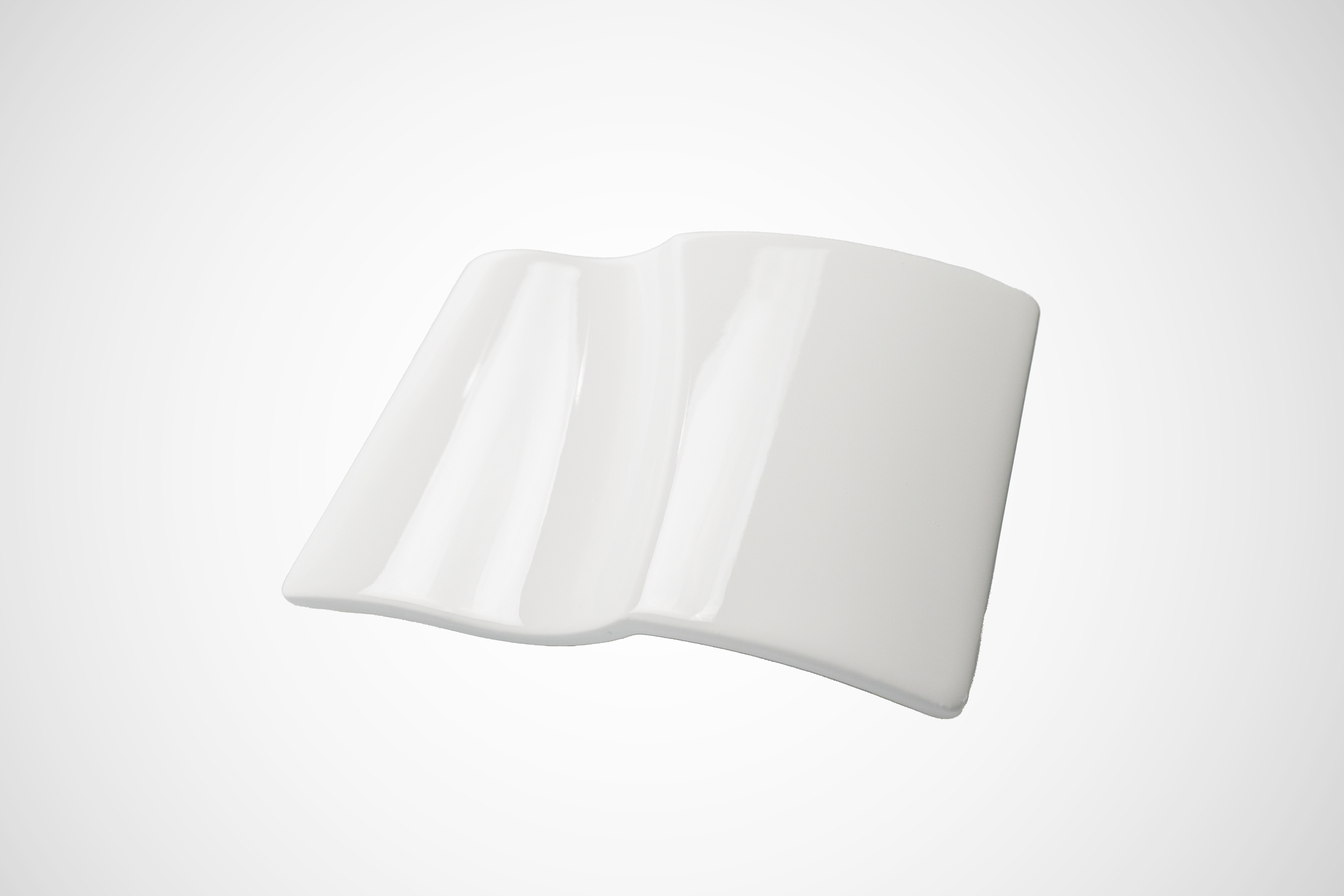

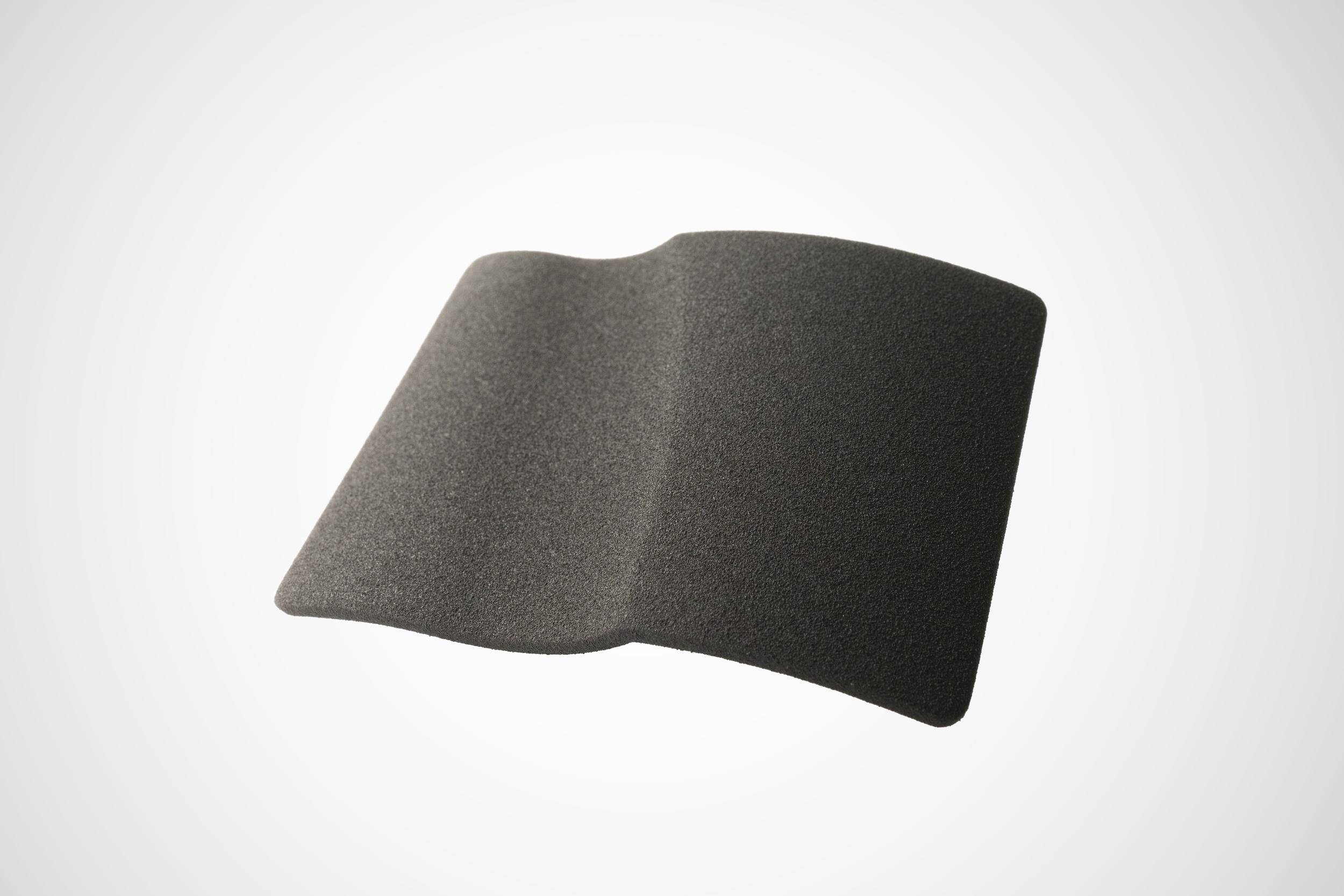

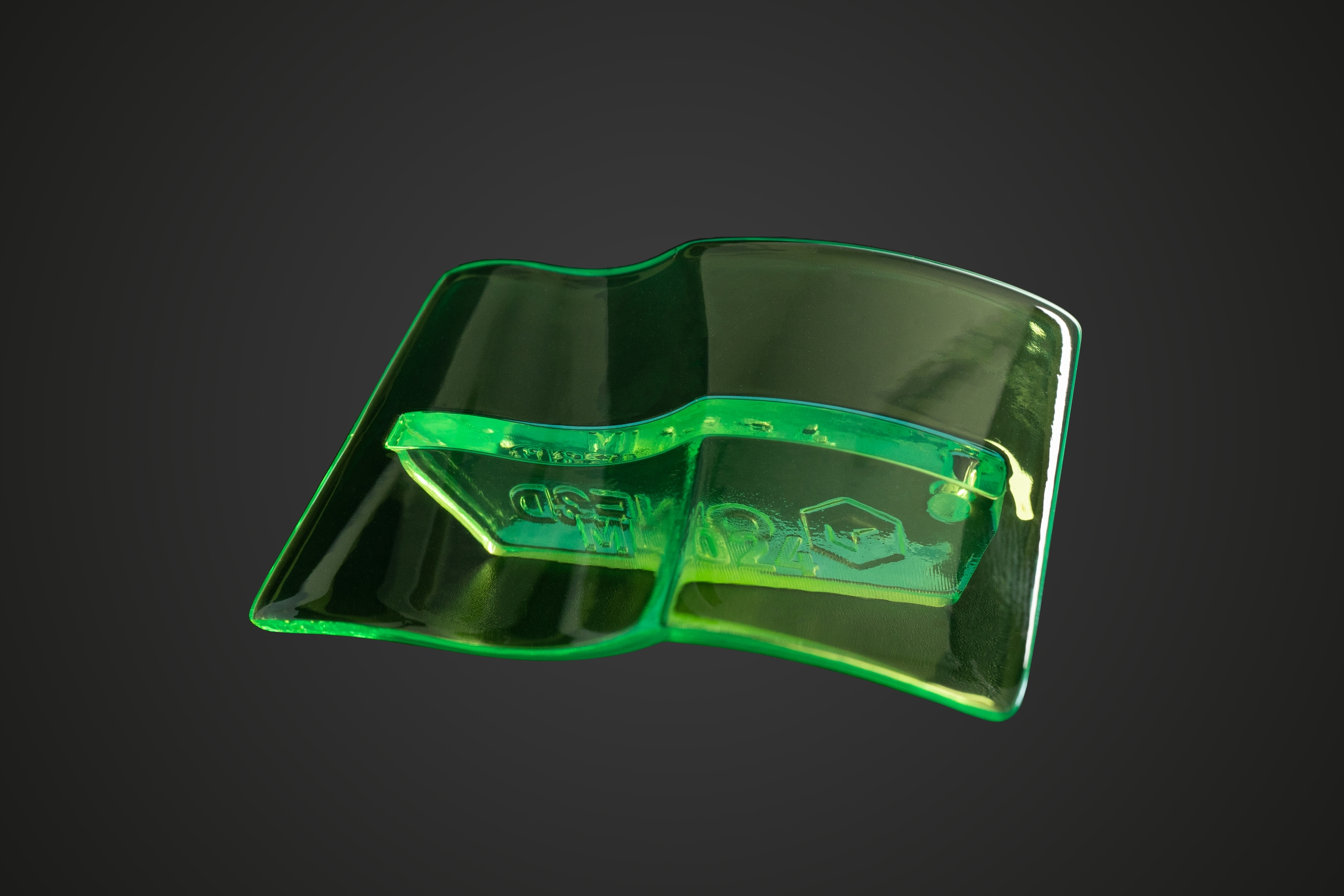

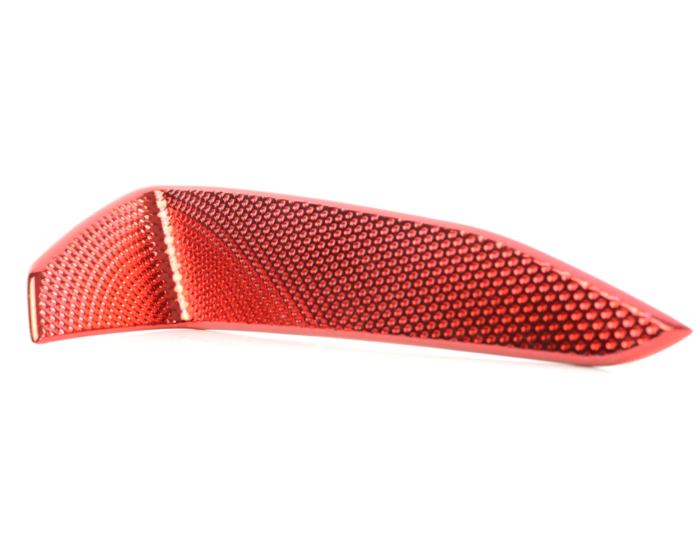

Wet coating is mainly used for design parts and visual prototypes produced in smaller batches.

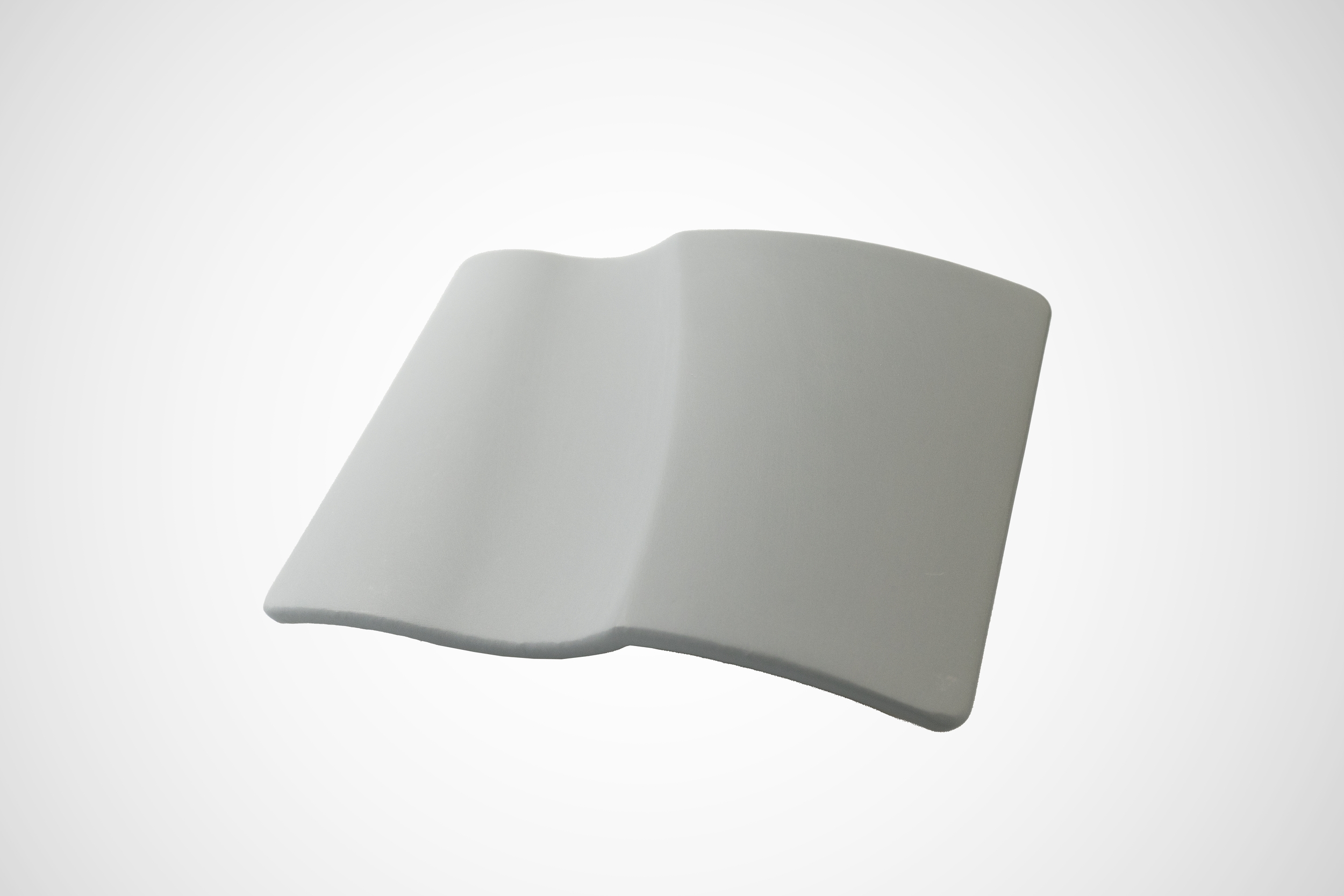

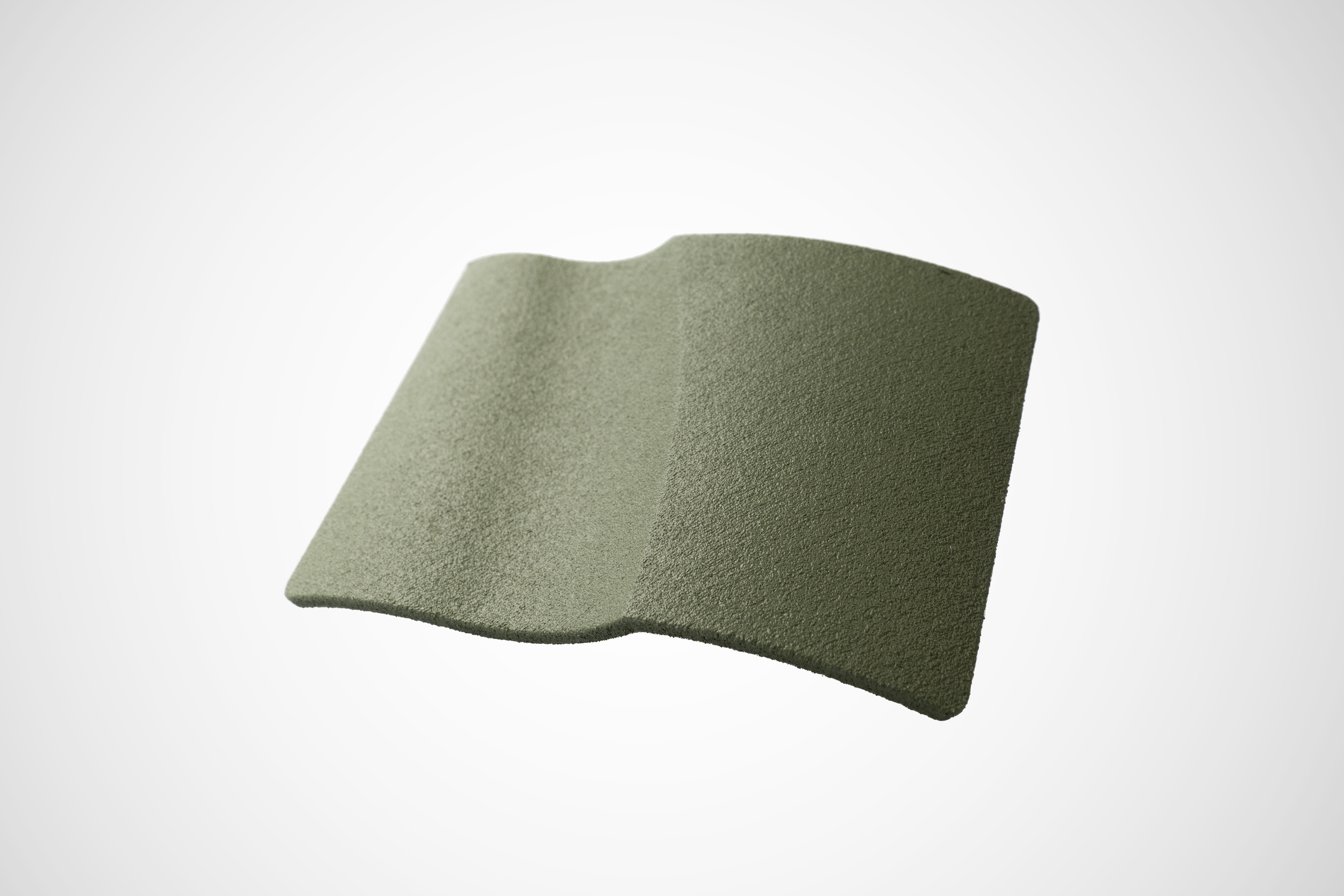

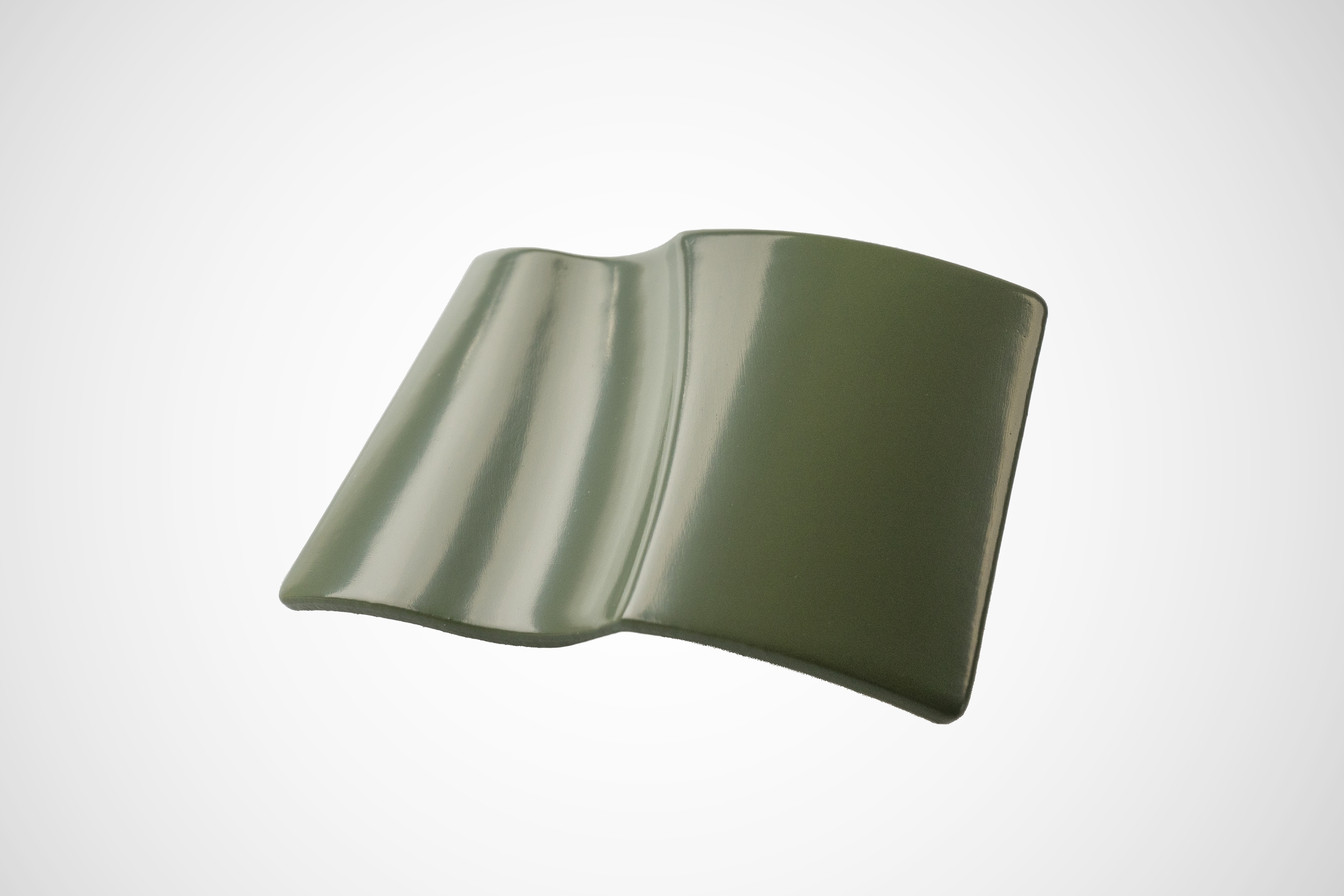

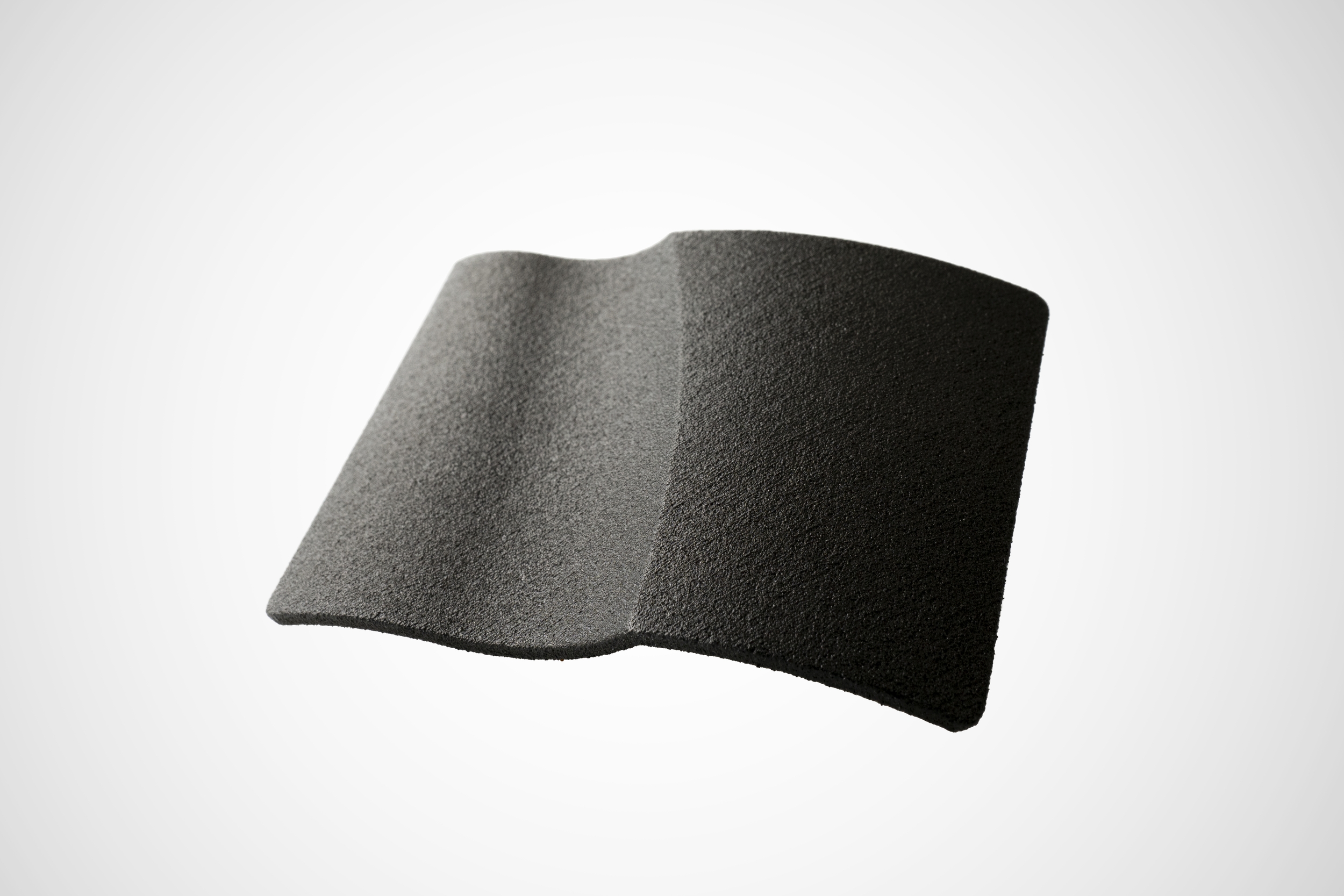

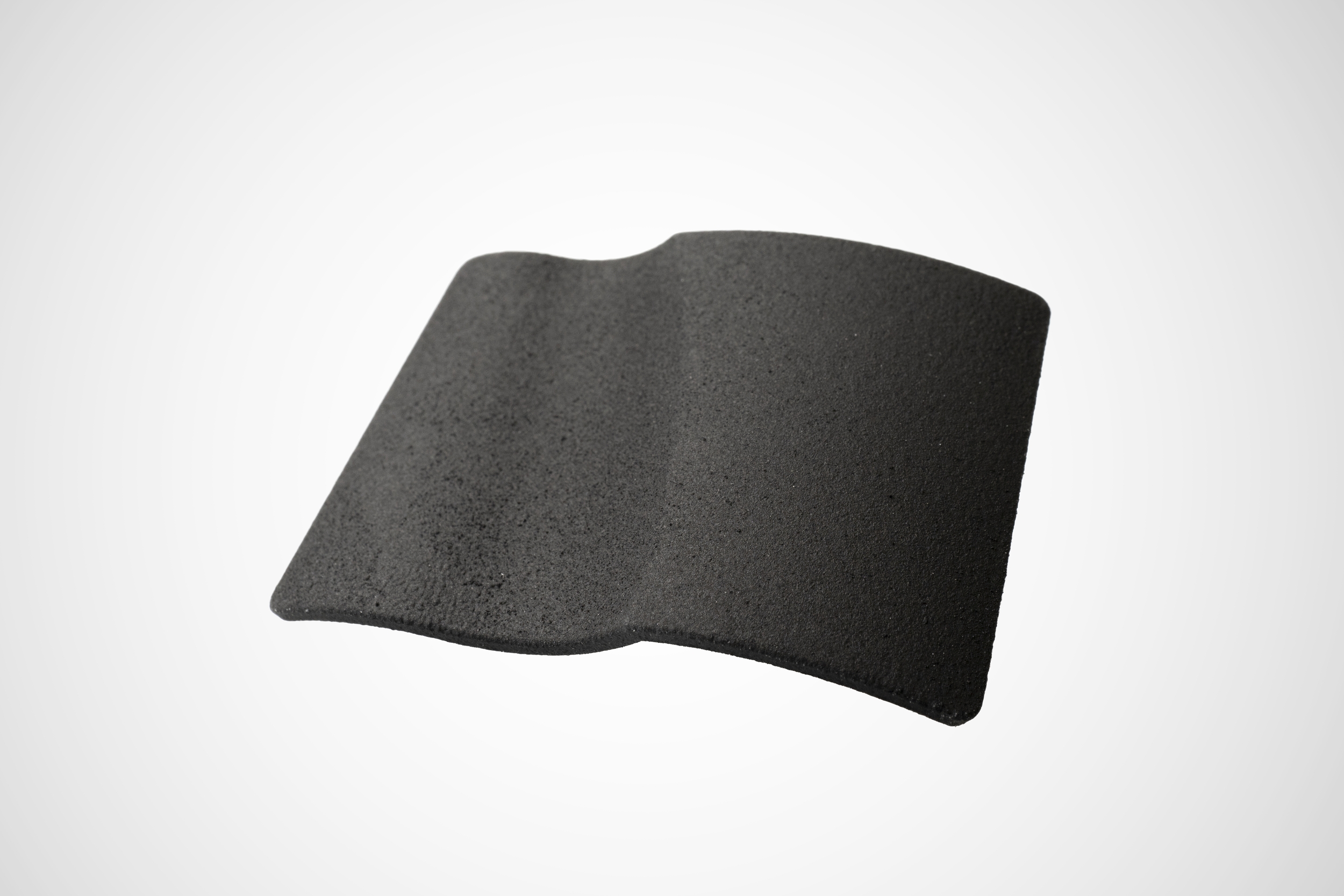

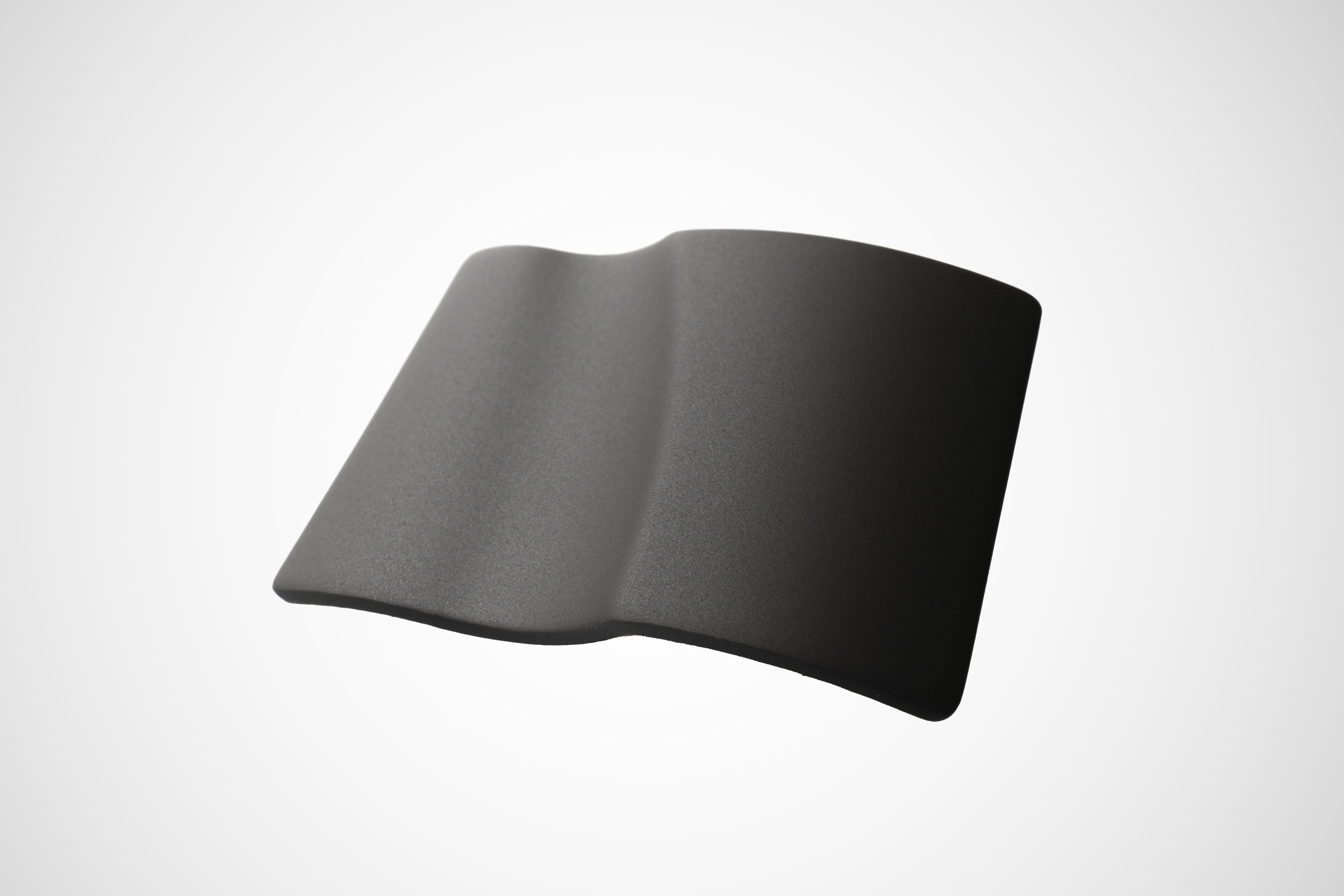

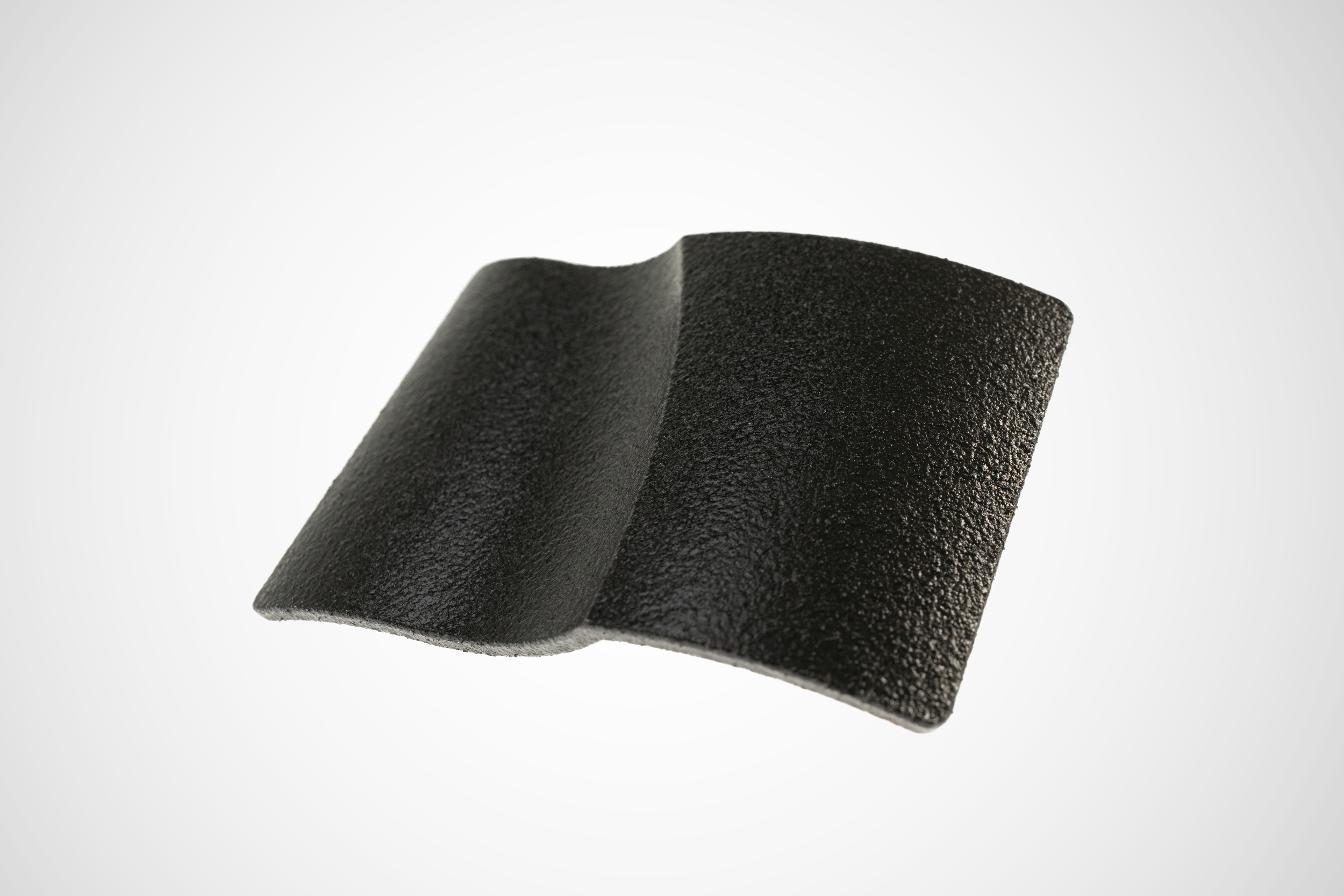

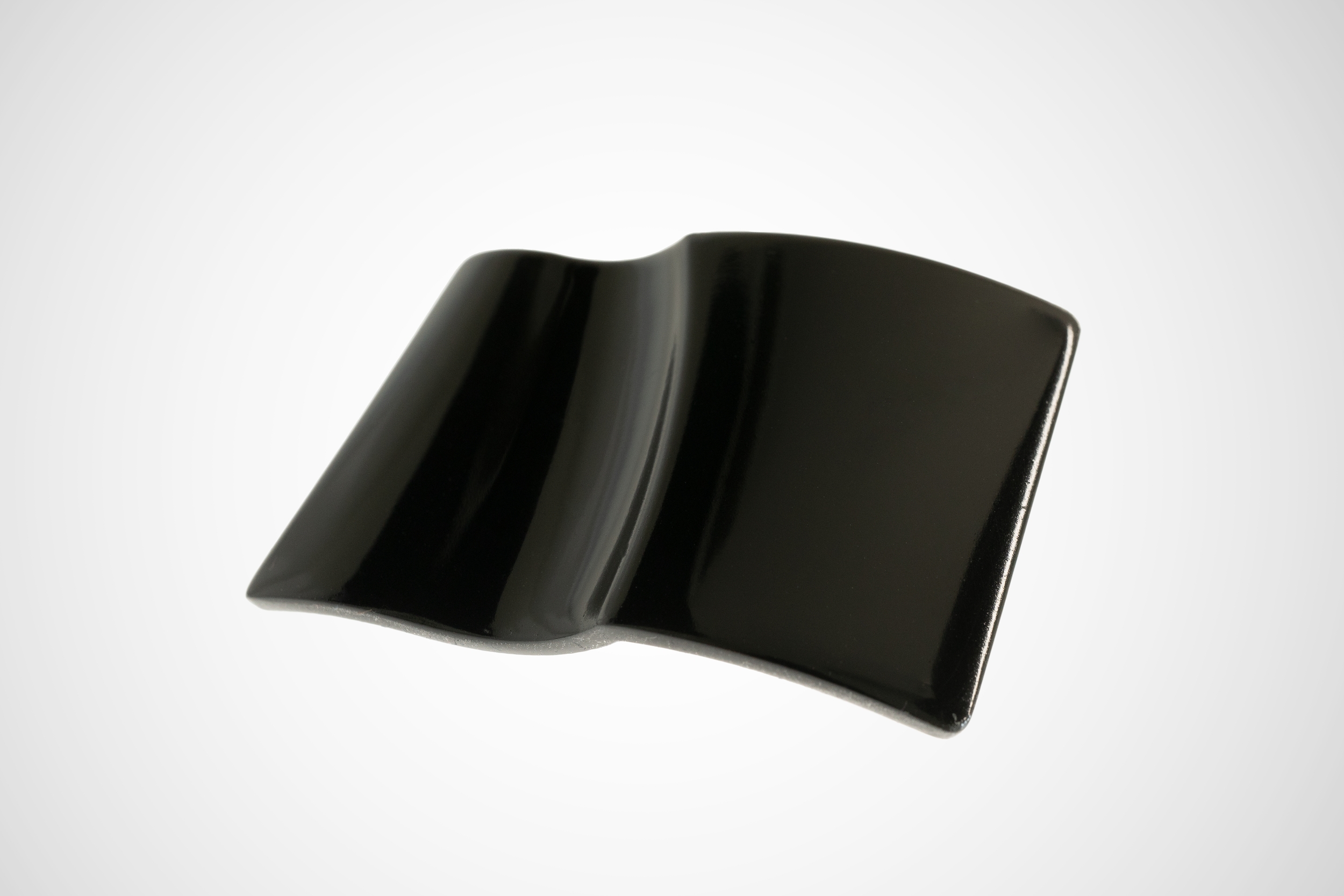

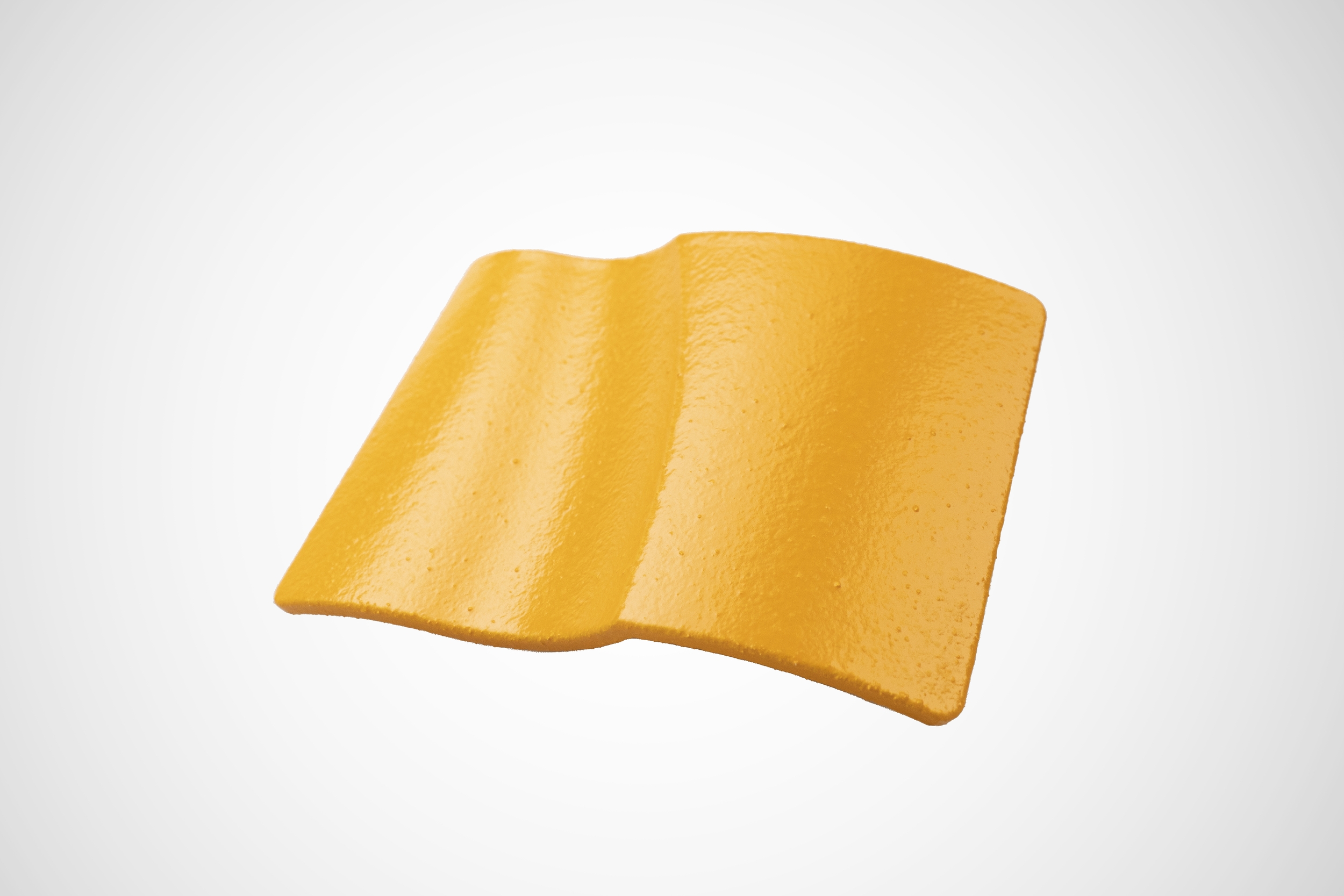

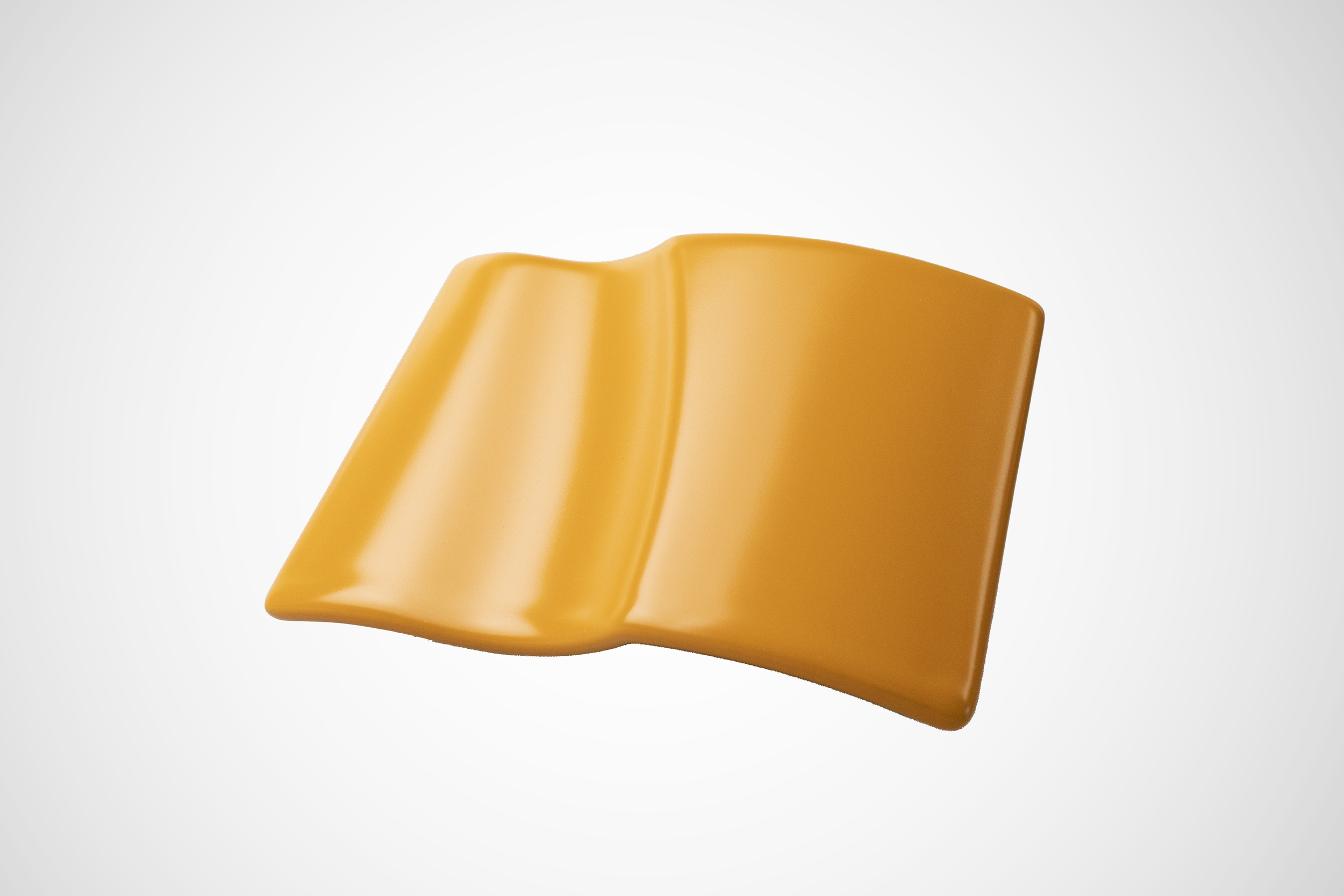

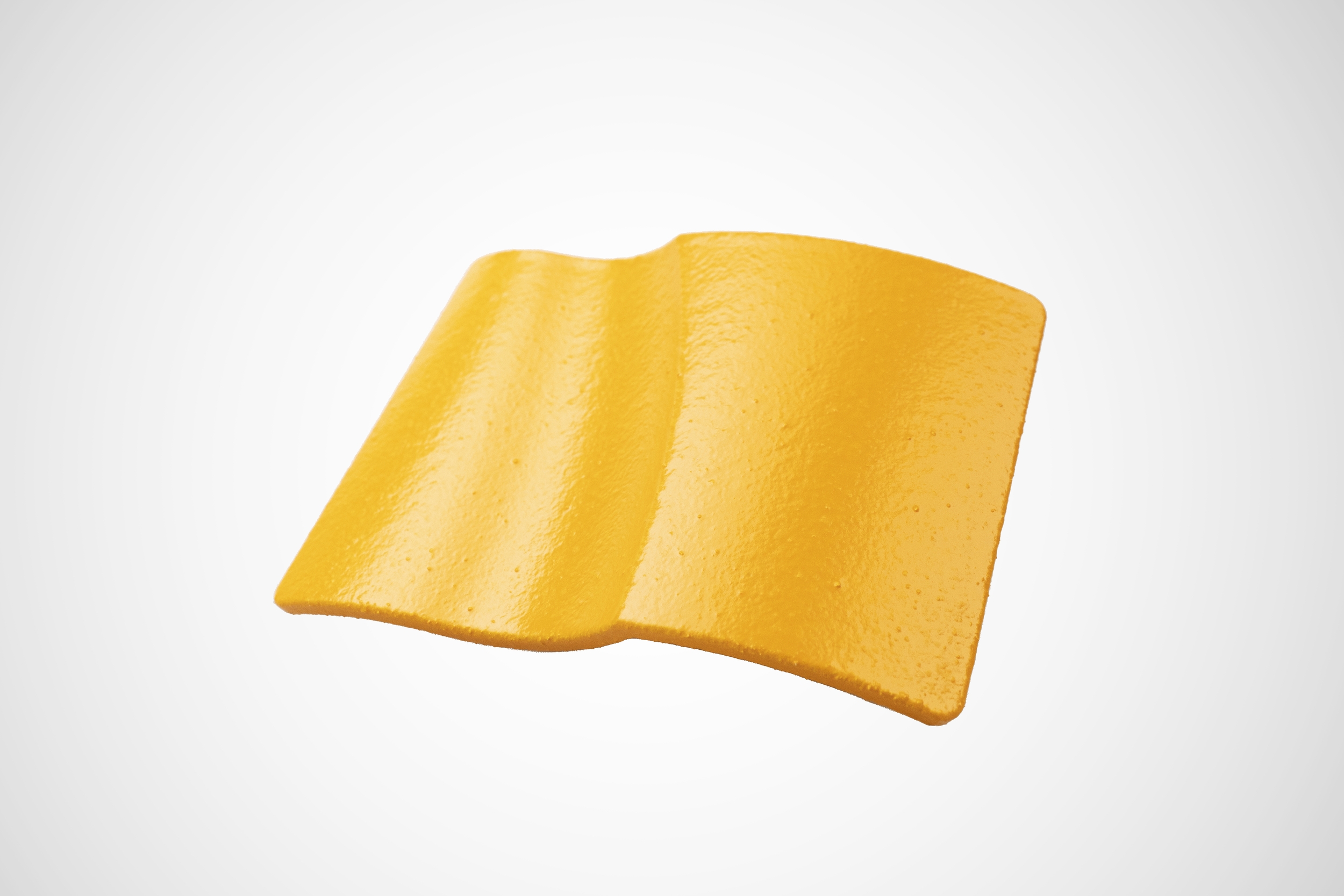

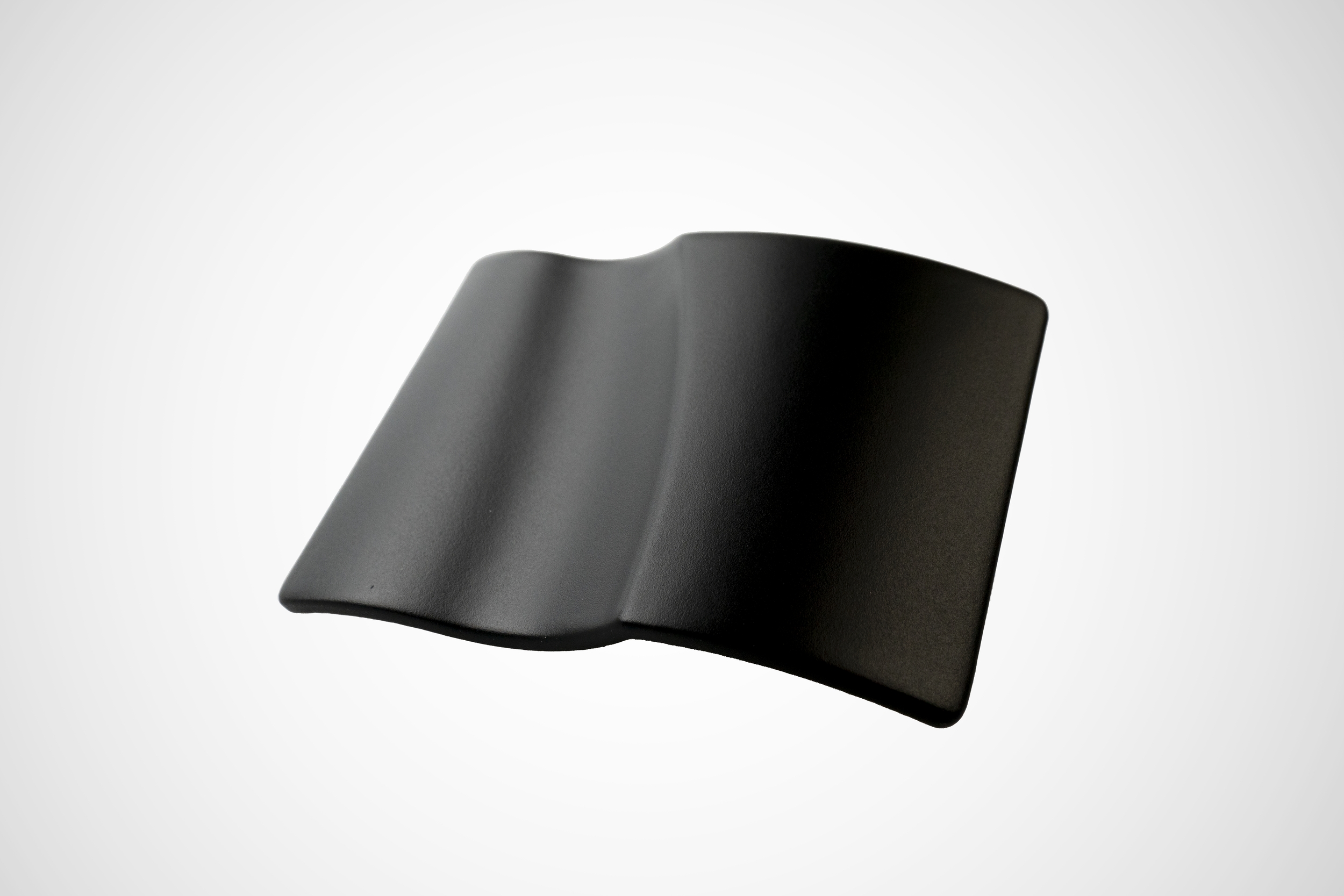

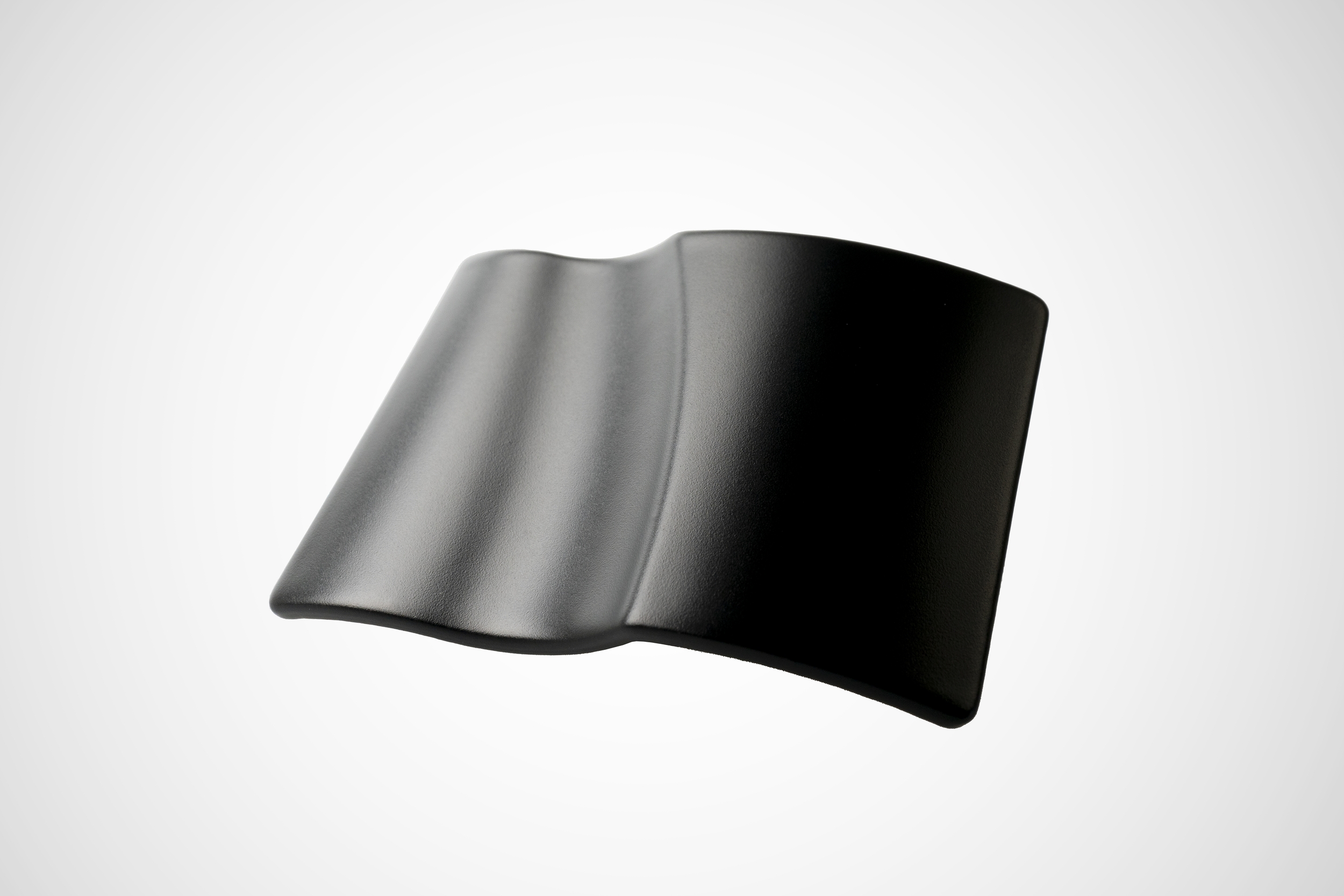

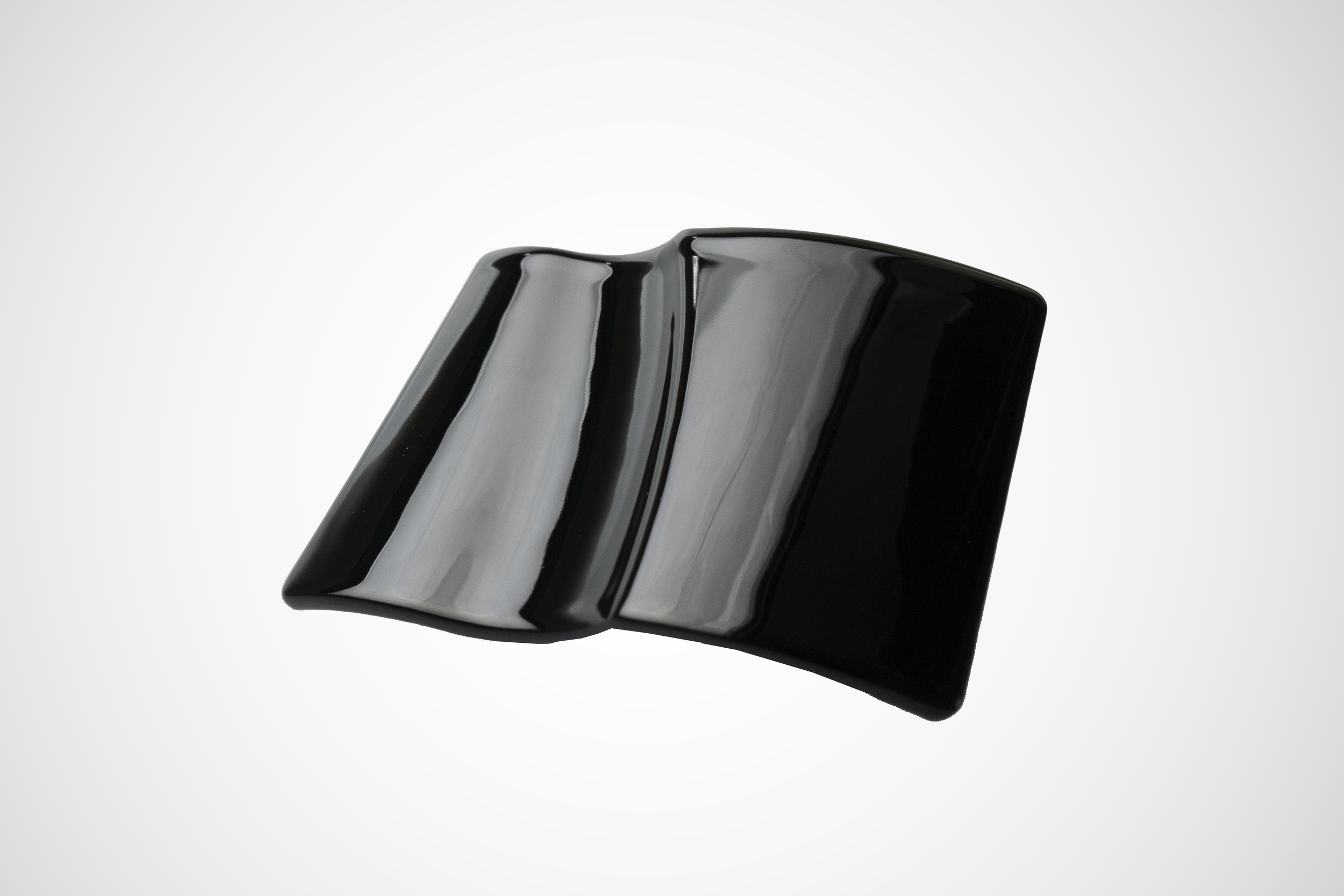

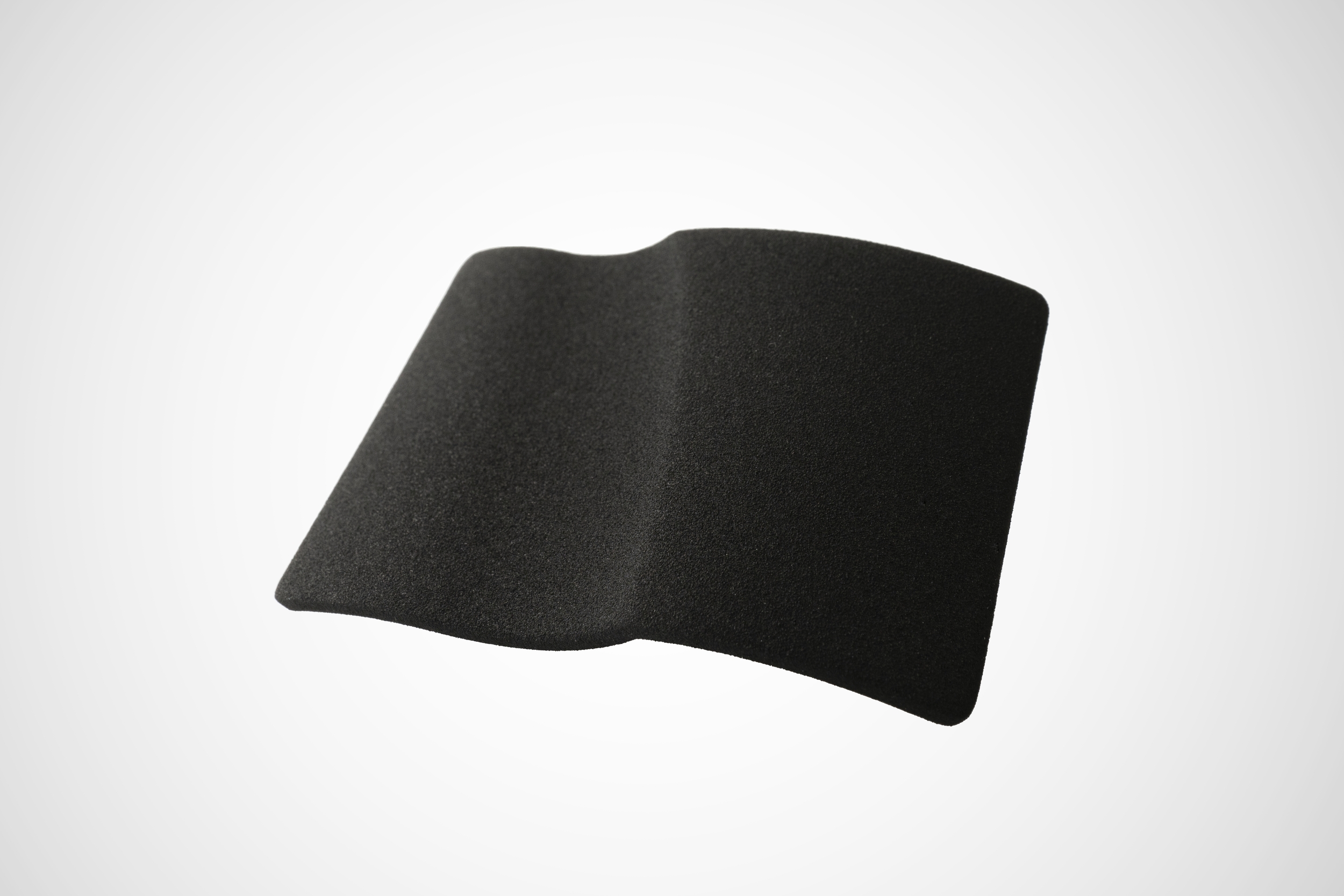

Thanks to the coating it is possible to achieve a very realistic appearance of high quality, different surface properties and roughness or accurate RAL color shades.

Main advantages

- large selection of final color shades according to RAL

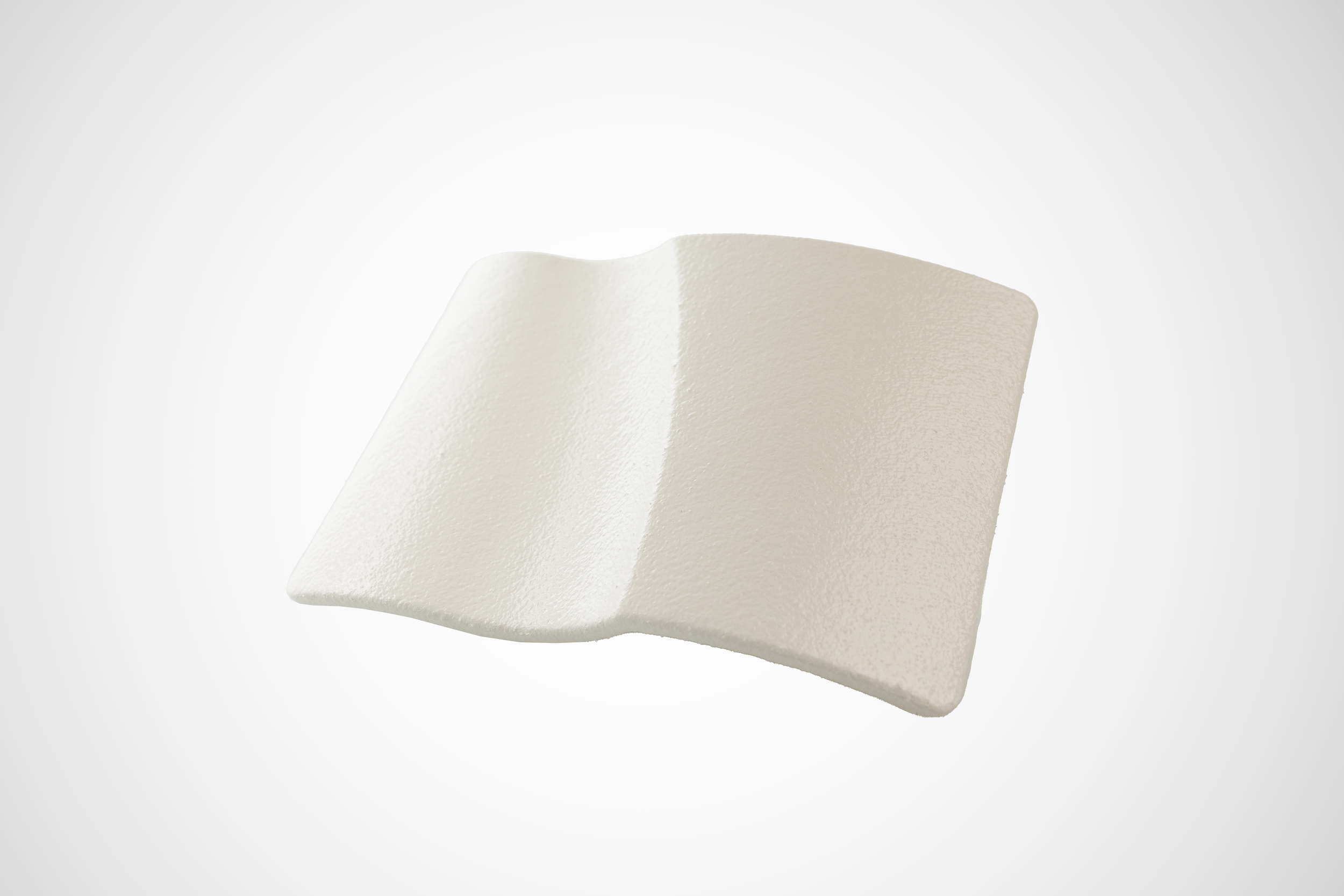

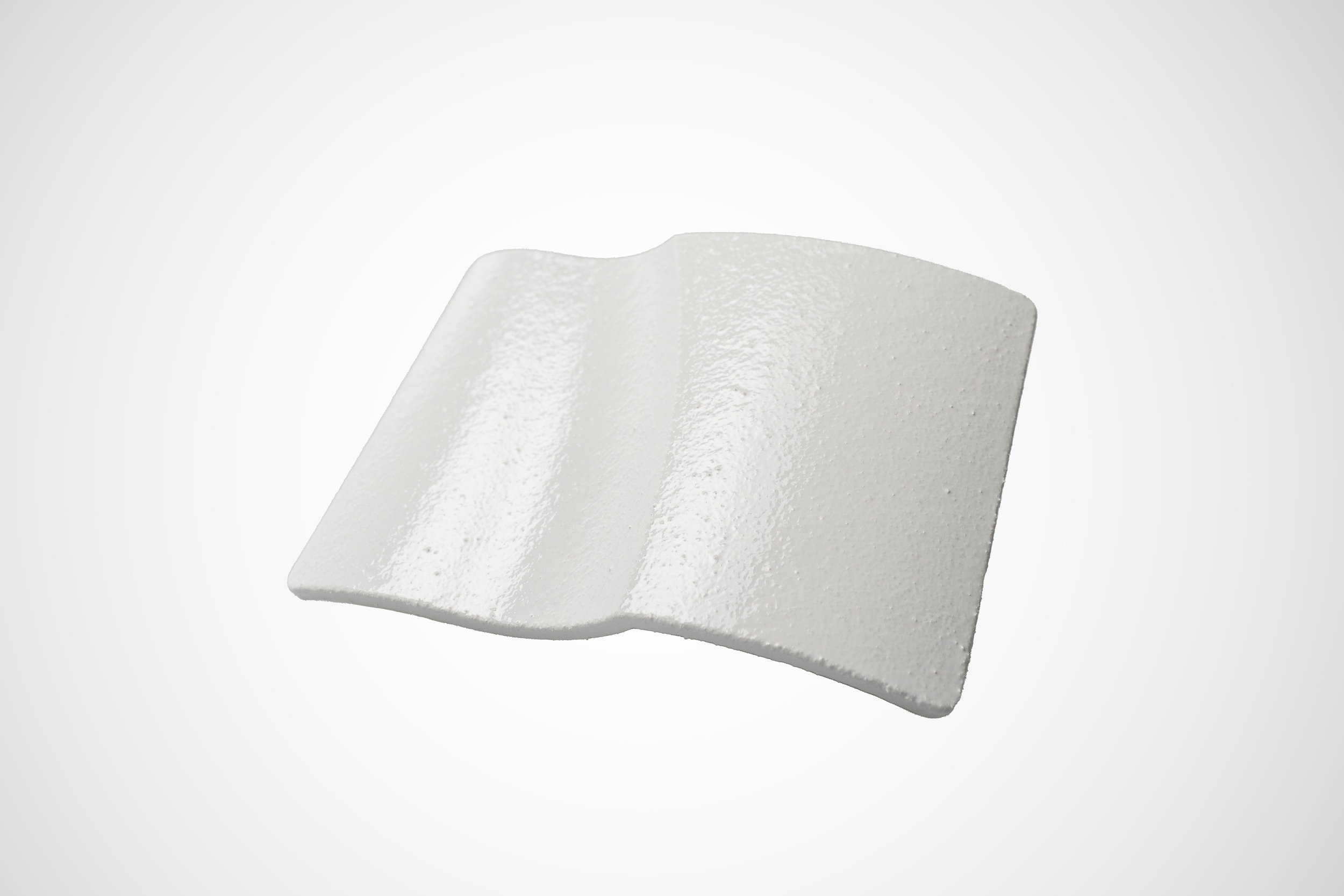

- surface roughness variability

- imitation of different types of surfaces according to specific requirements

Technological specifications

| Maximum part size | up to 3 m (larger parts upon consultation) |

| Types of wet coating | filling, paint spraying, primer spraying, coating, graining |

| Compatible Materials | PA2200, PA3200GF, Waterclear, HP PA12, HP TPU |