What is it?

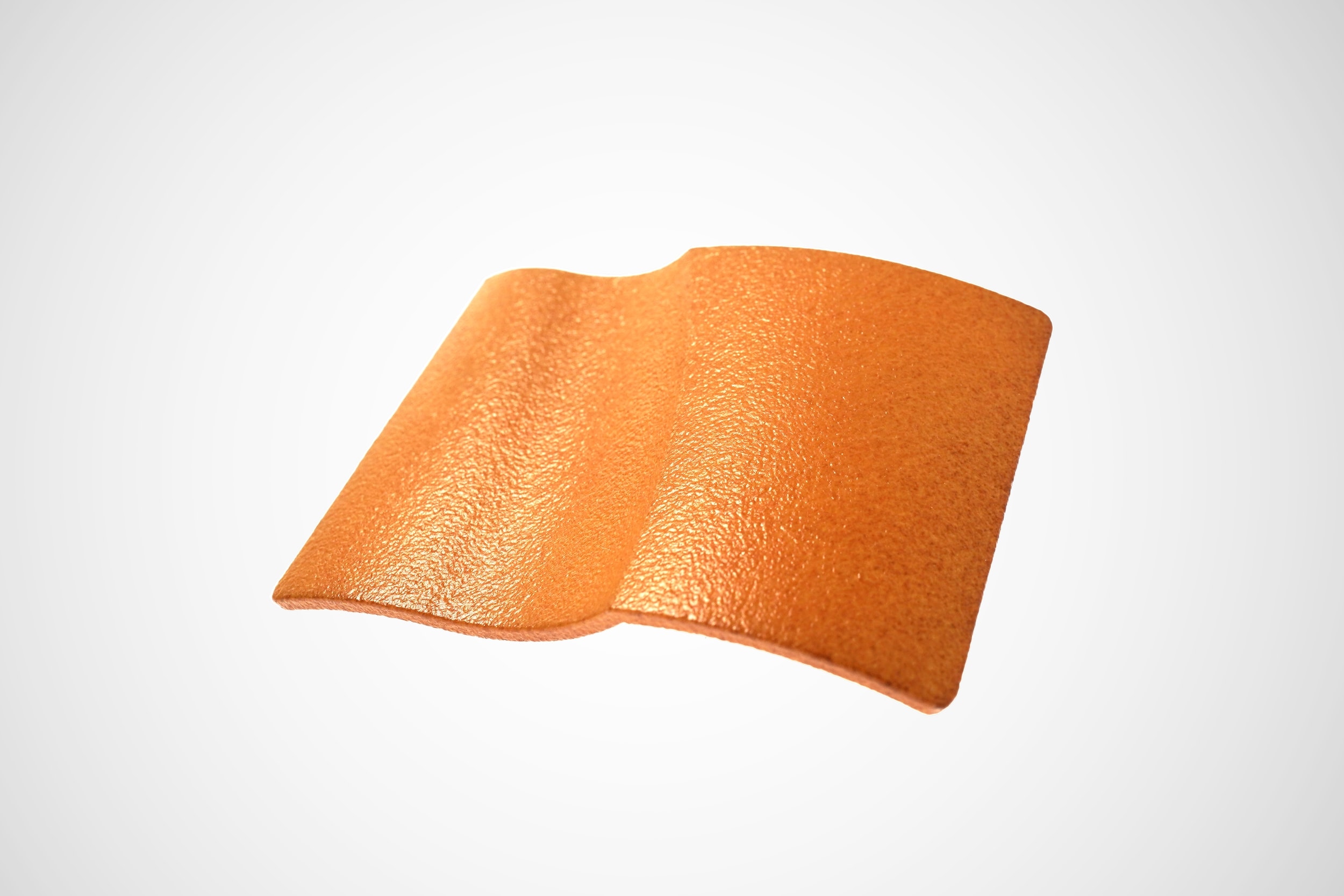

For chemical smoothing, we use the AMT PostPro3D and DyeMansion PowerFuse S systems, which uses a special chemical compound to smooth the surface.

This compound evaporates in the first stage of the process, filling the working chamber with mist. It then condenses on the surface of the part, etching its structure.

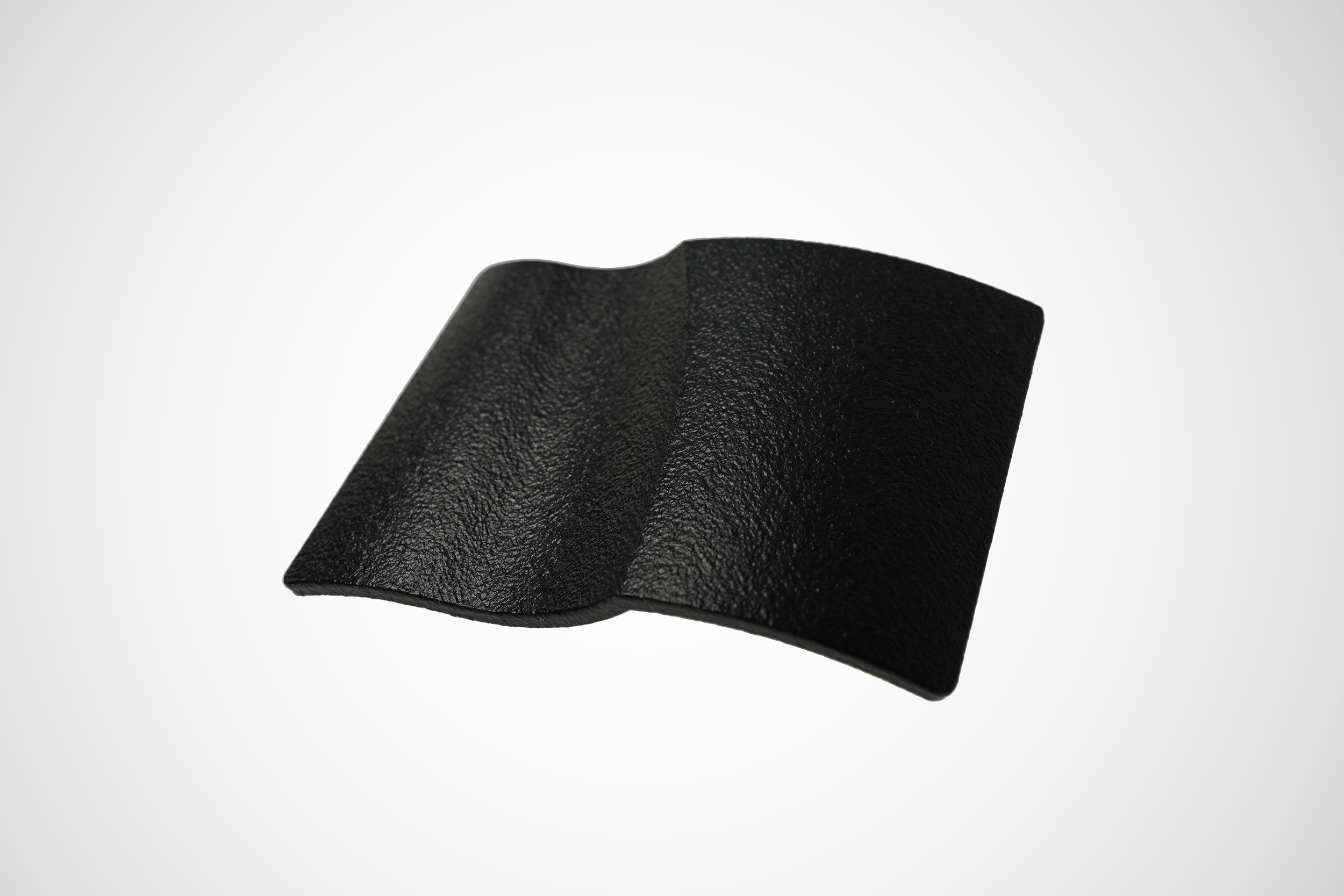

This is followed by the smoothing of sharp unevenness, thereby unifying the surface

of the part. In the final stage, the remaining mist is ventilated from the chamber

and the surface of the processed parts.

What is it used for?

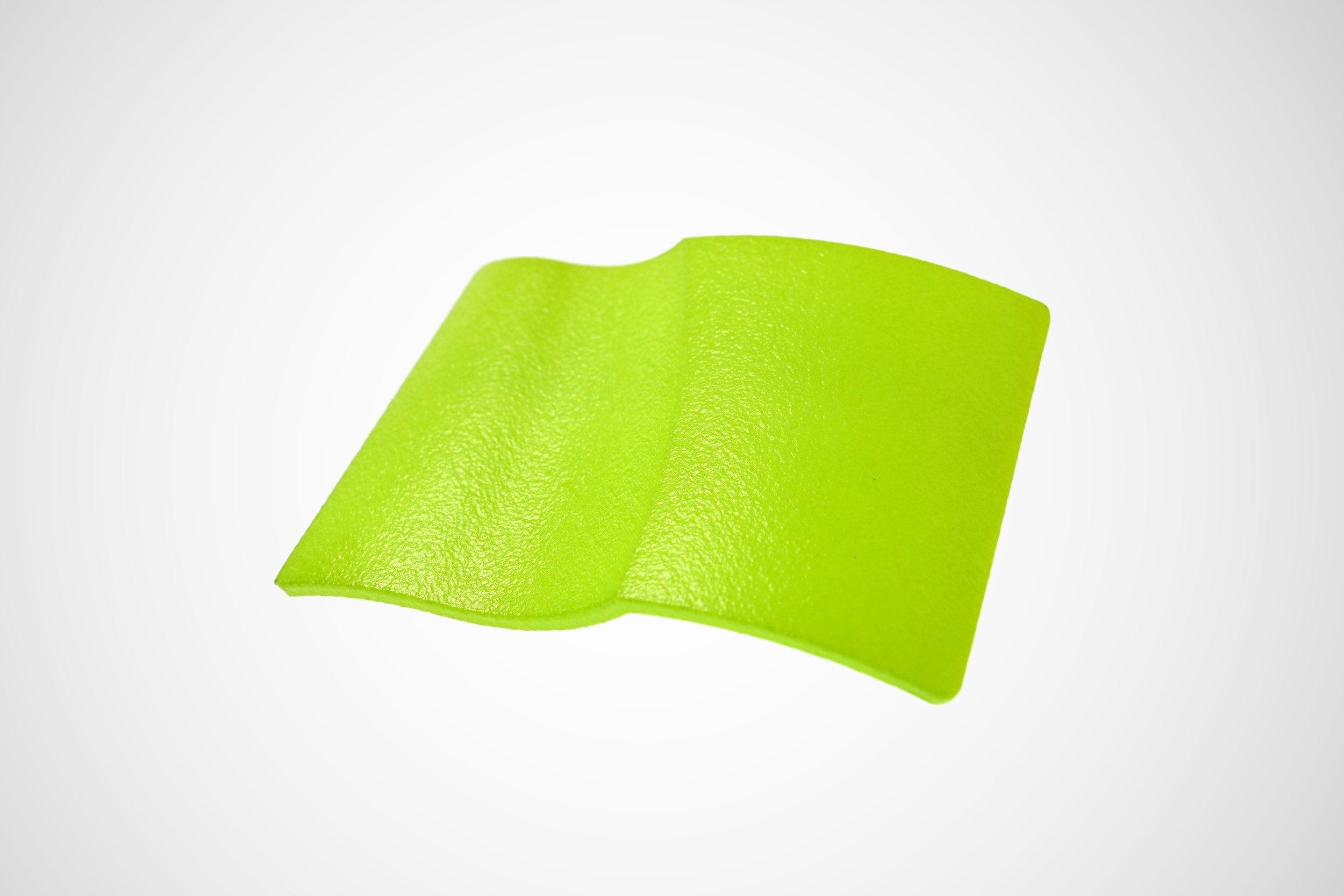

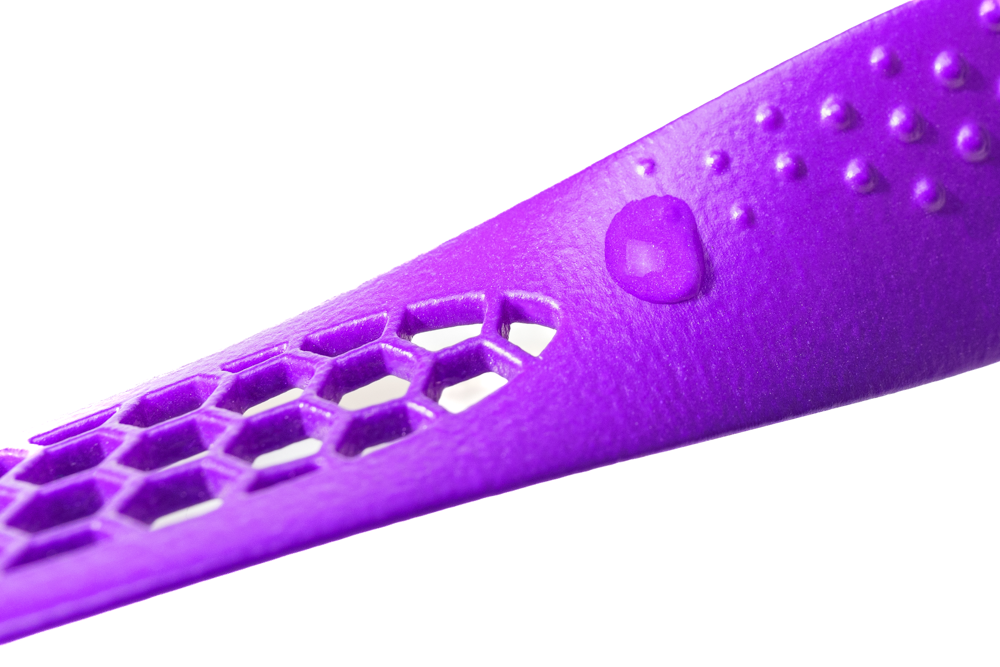

Surfaces of a wide range of materials can be processed by chemical smoothing. Closing surface pores and smoothing unevenness increases the resistance

of the surface to liquid penetration into the surface and makes it easier to maintain.

In addition, the use of this post-processing results in an increased capacity

for the deformation of the part. Since there are not as many stress concentrators

on the surface of the smoothed part, cracks and breaks will occur much later.

With this process, we achieve results very close to the production using conventional technology.

Main advantages

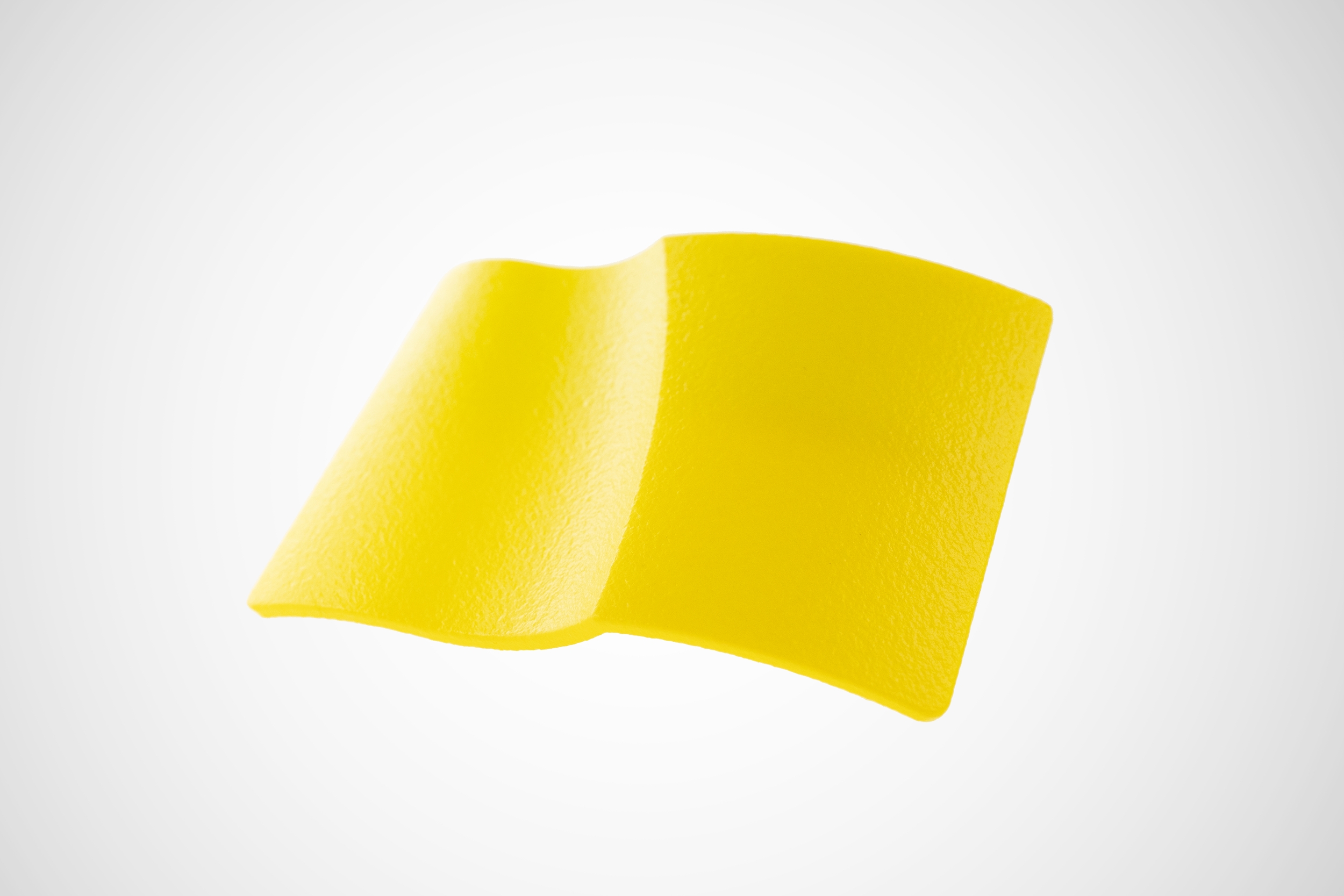

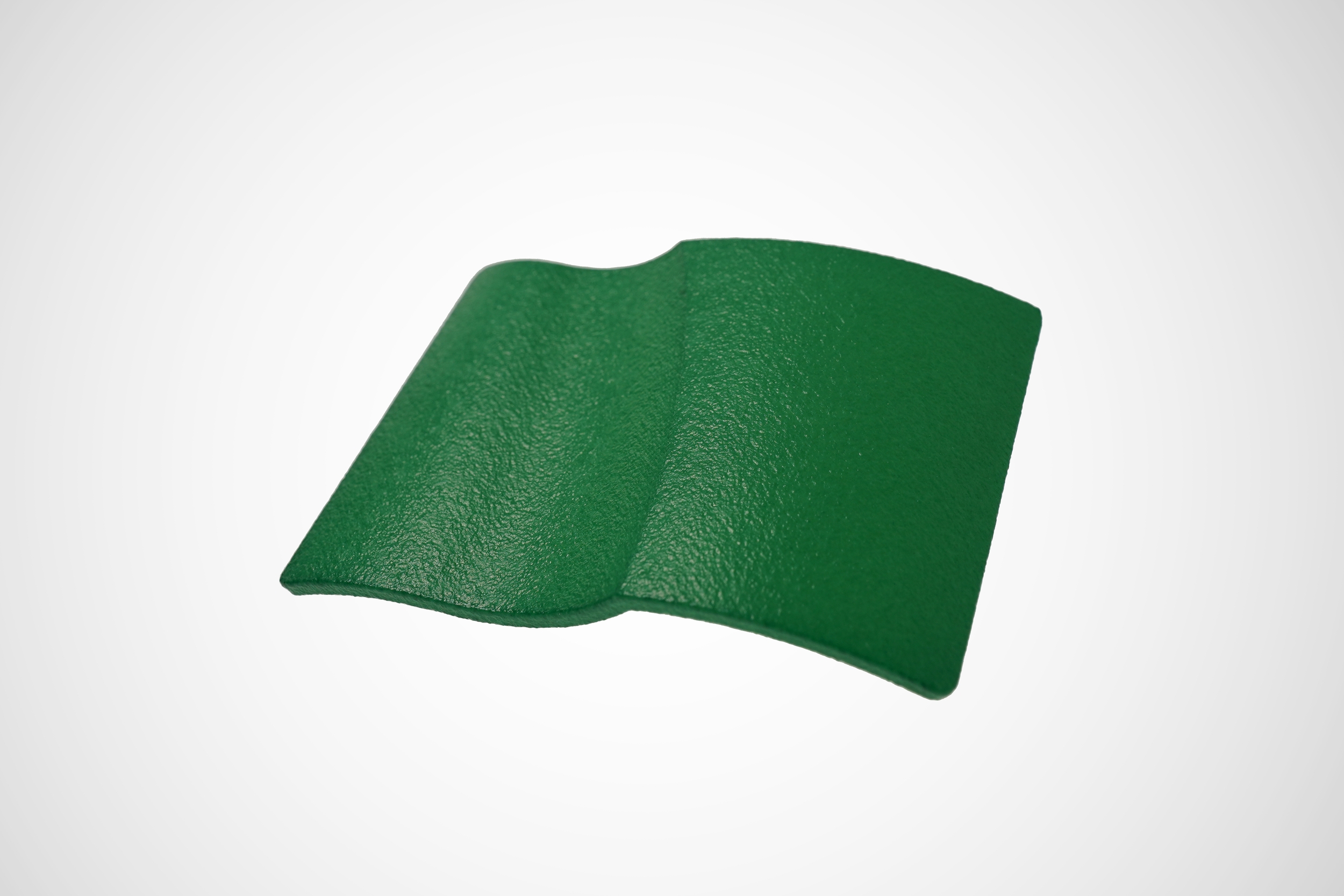

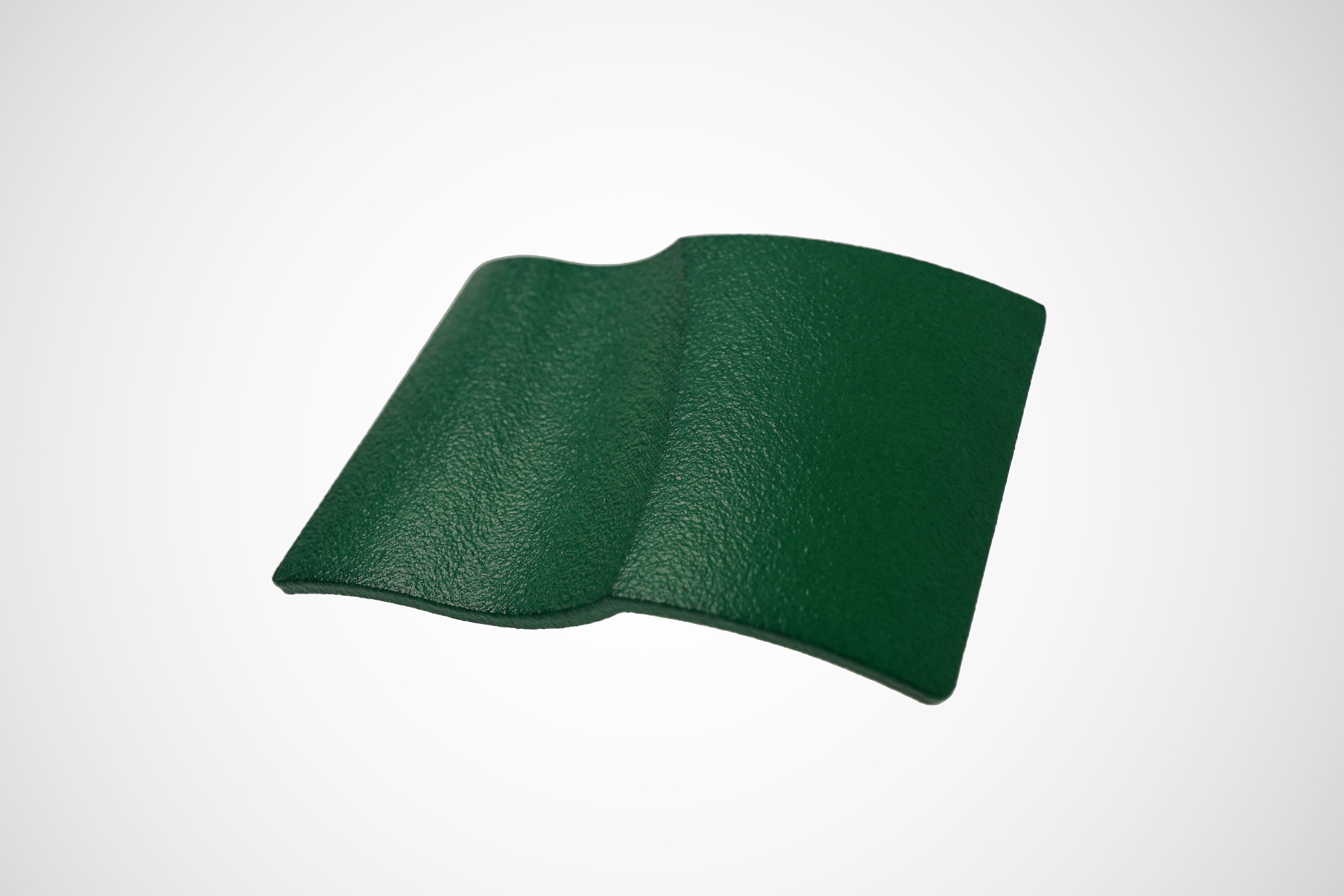

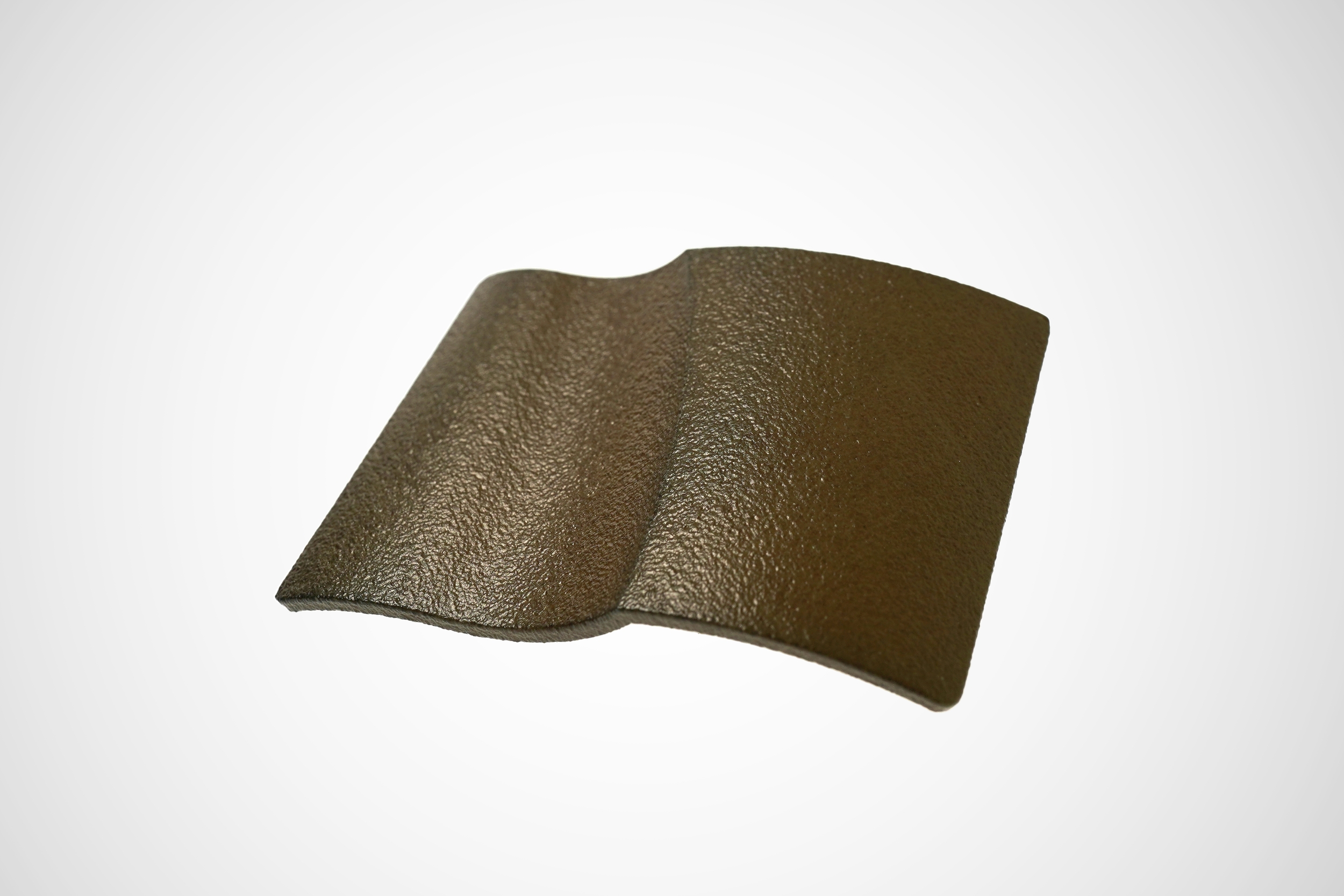

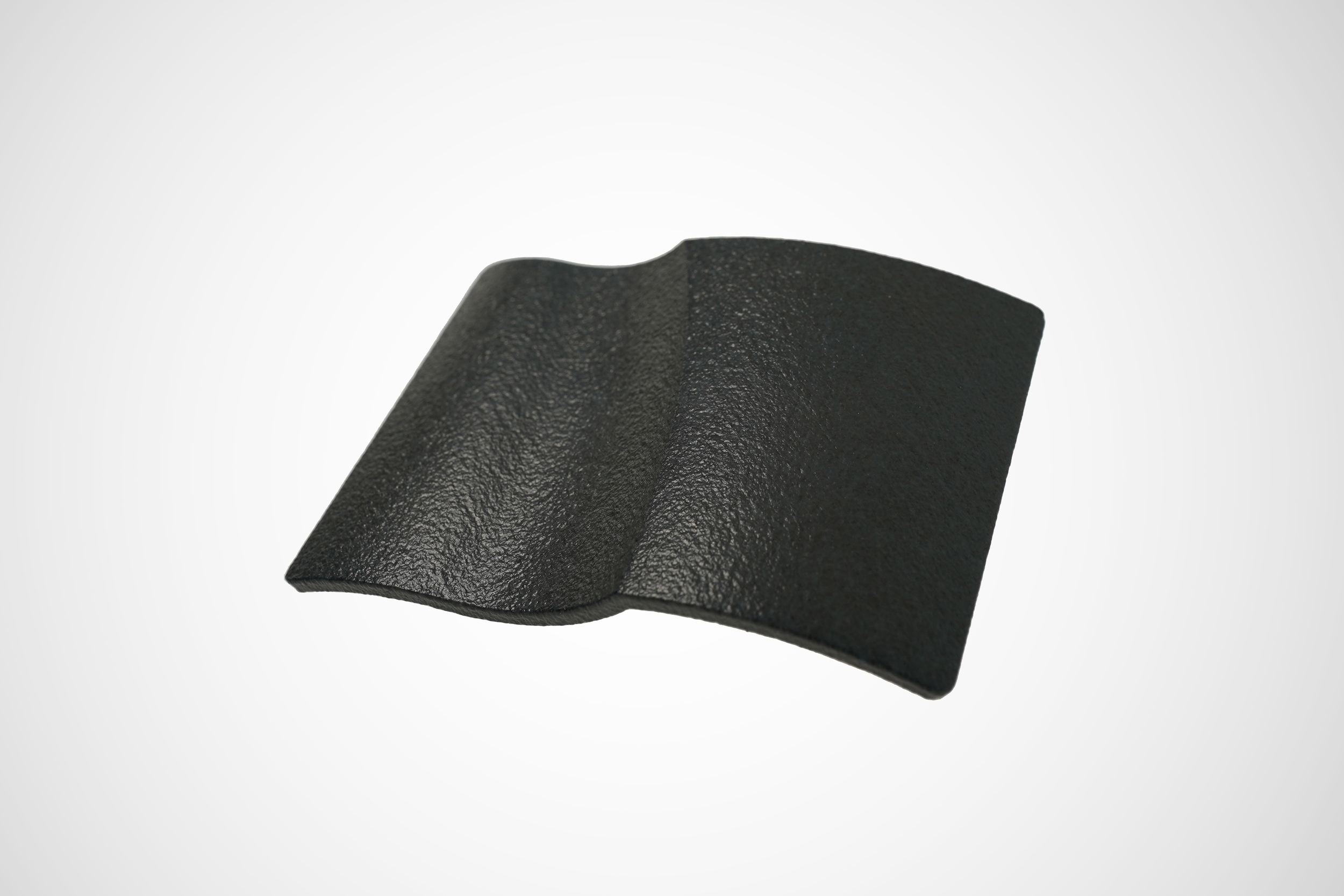

- water resistant surface

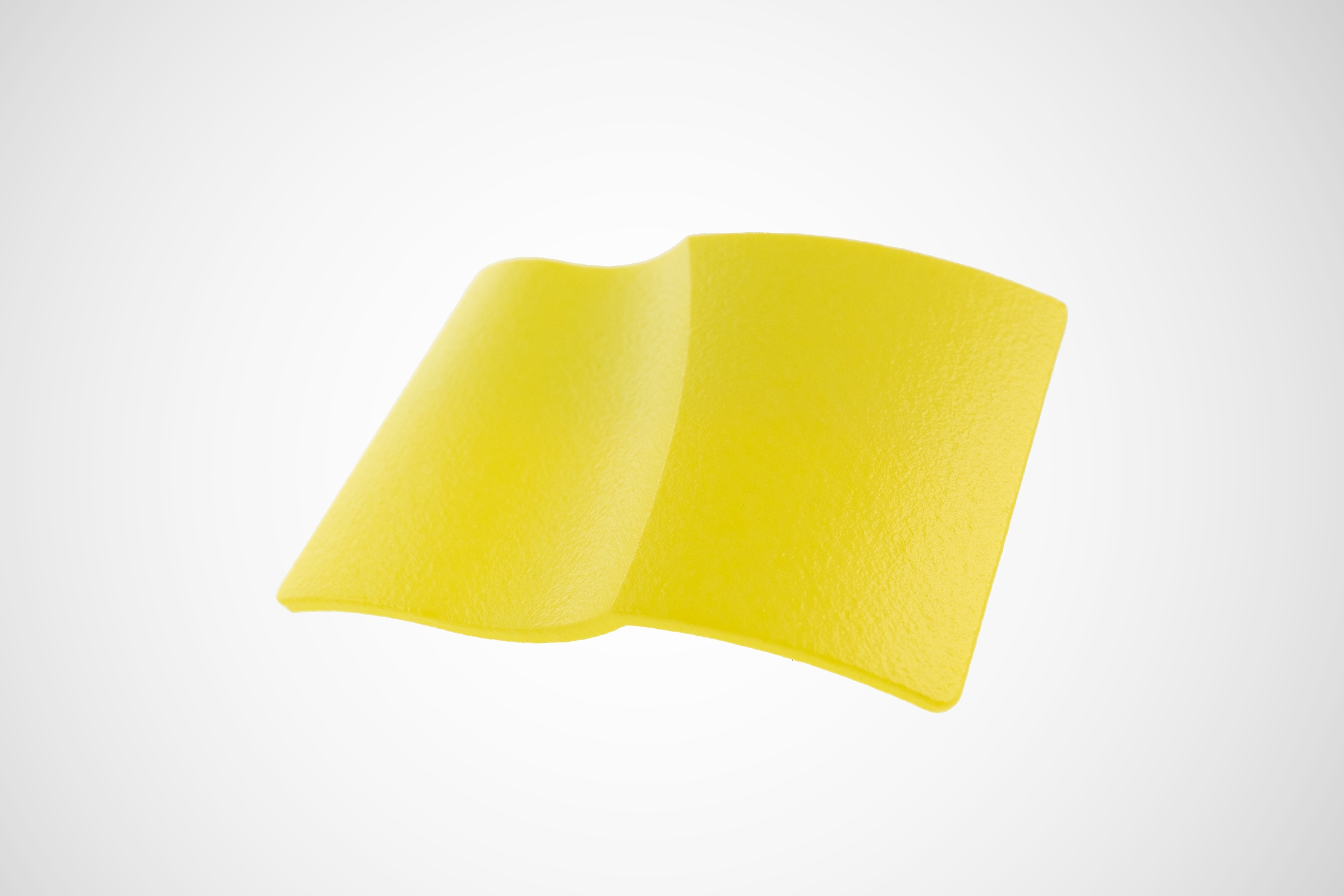

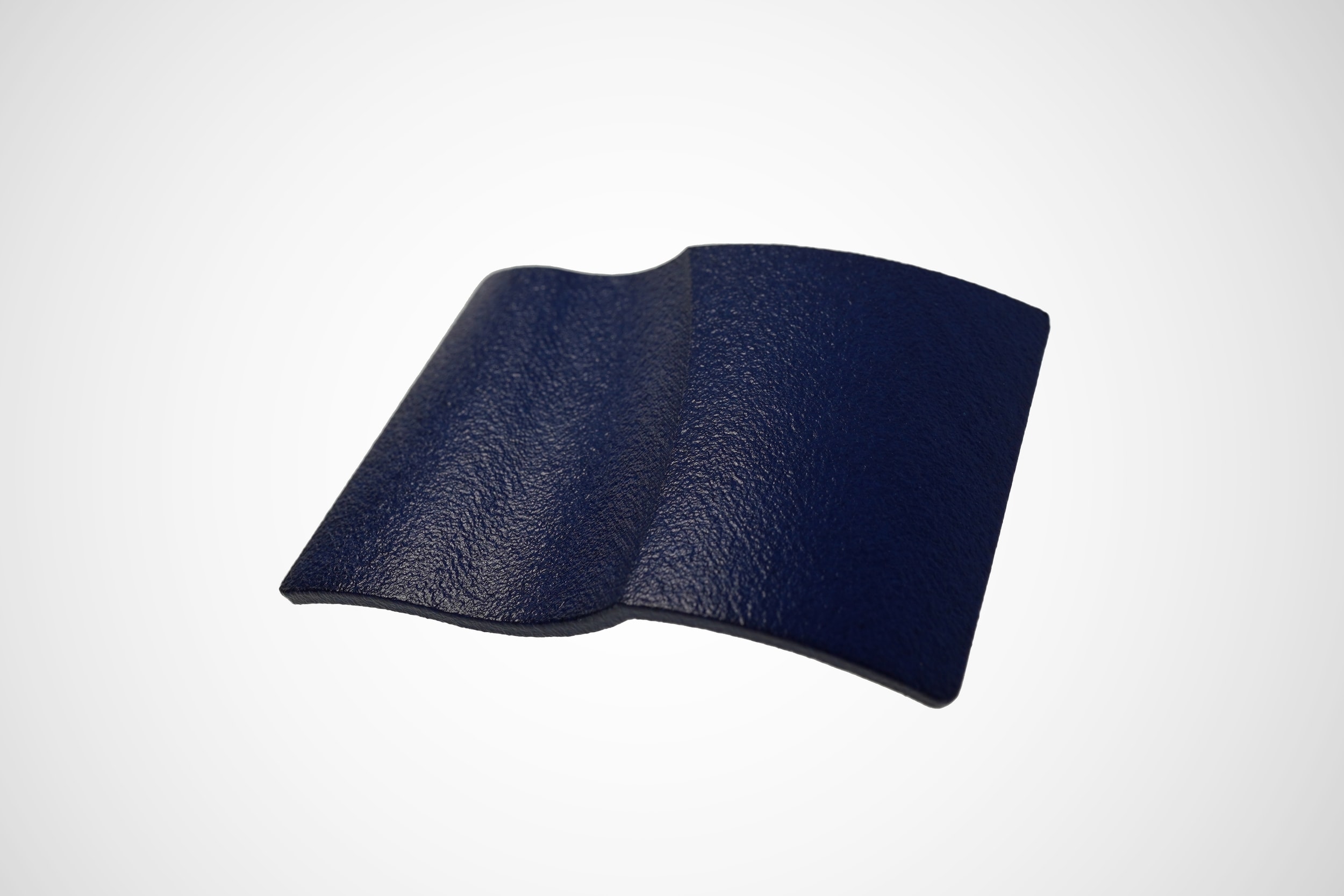

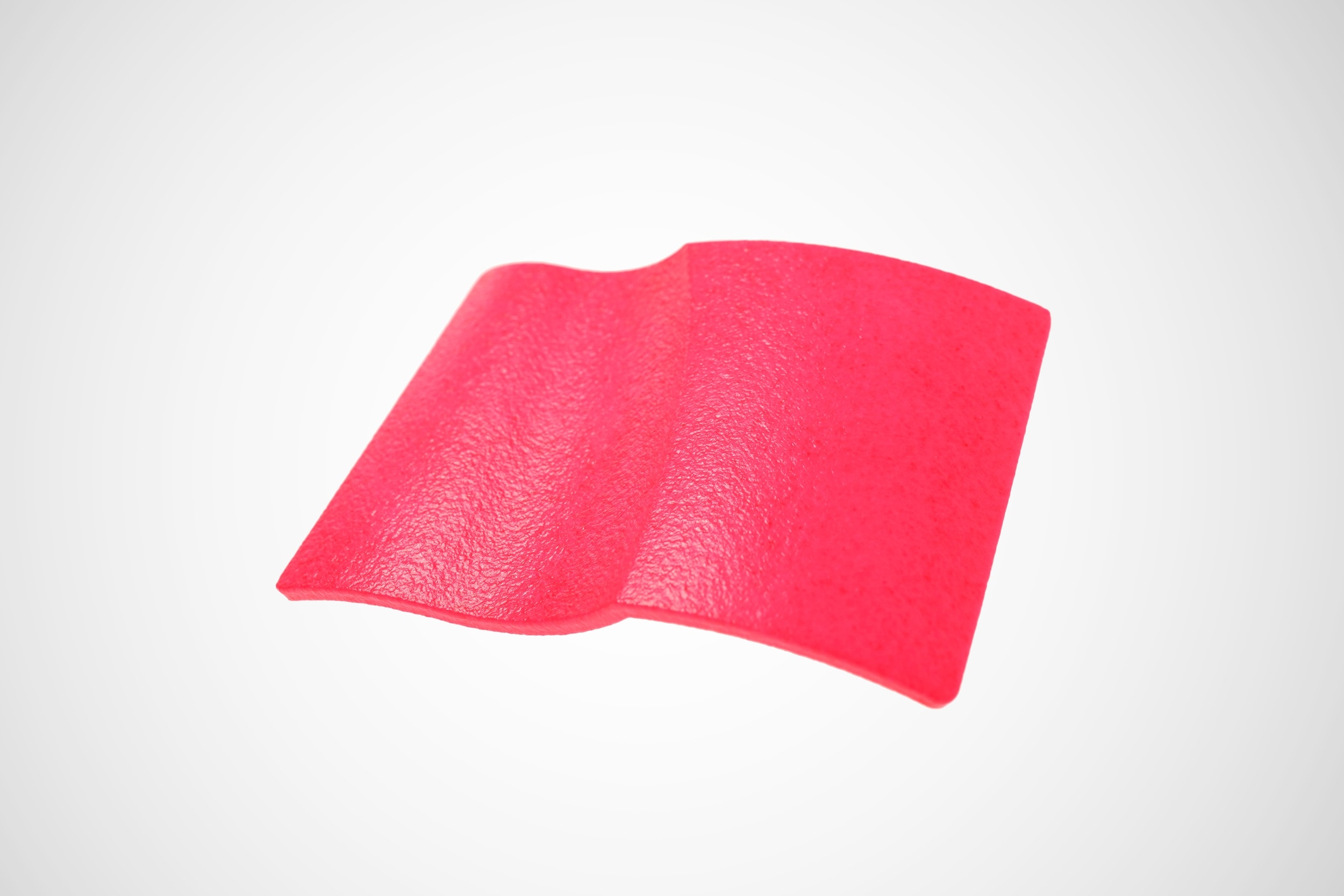

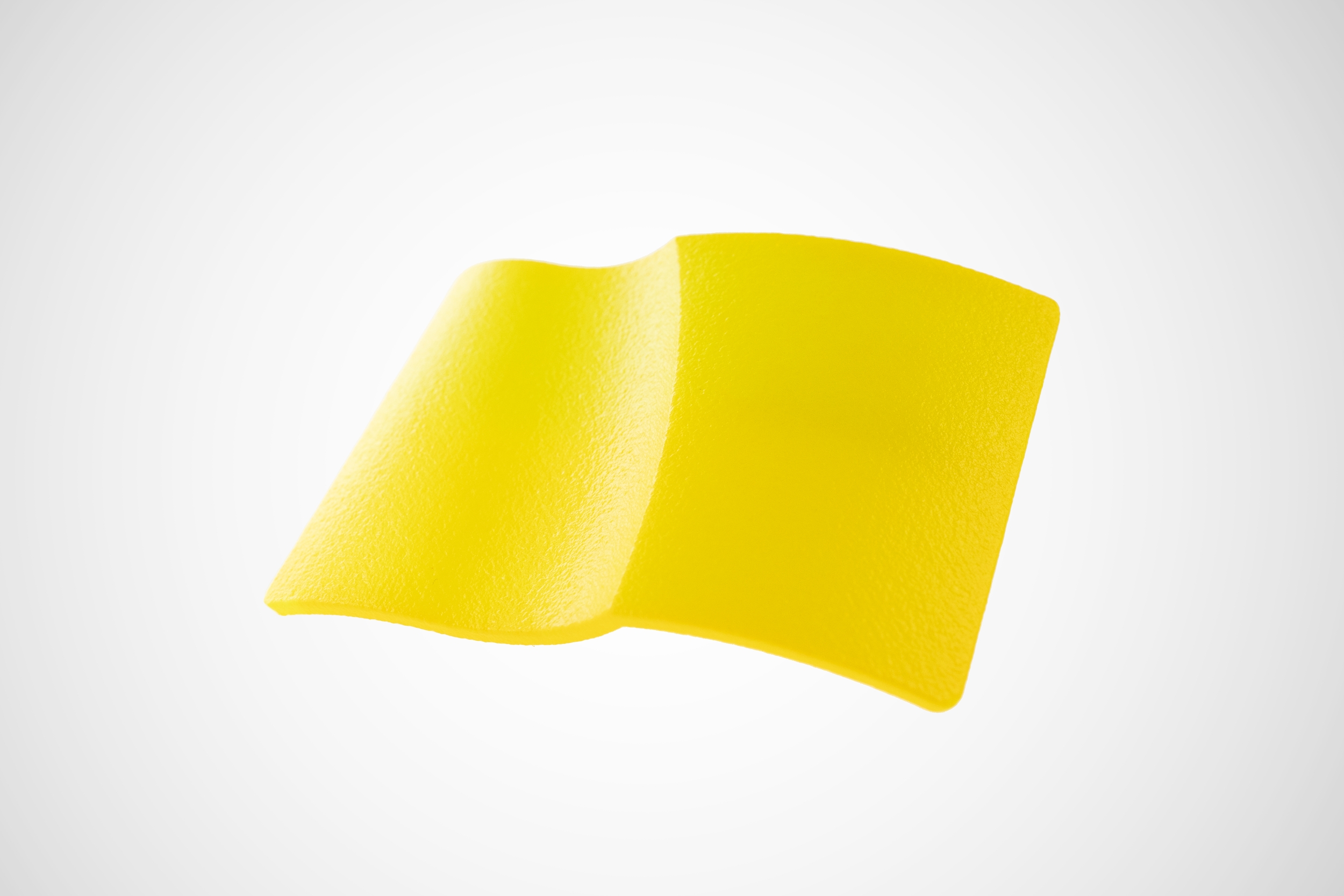

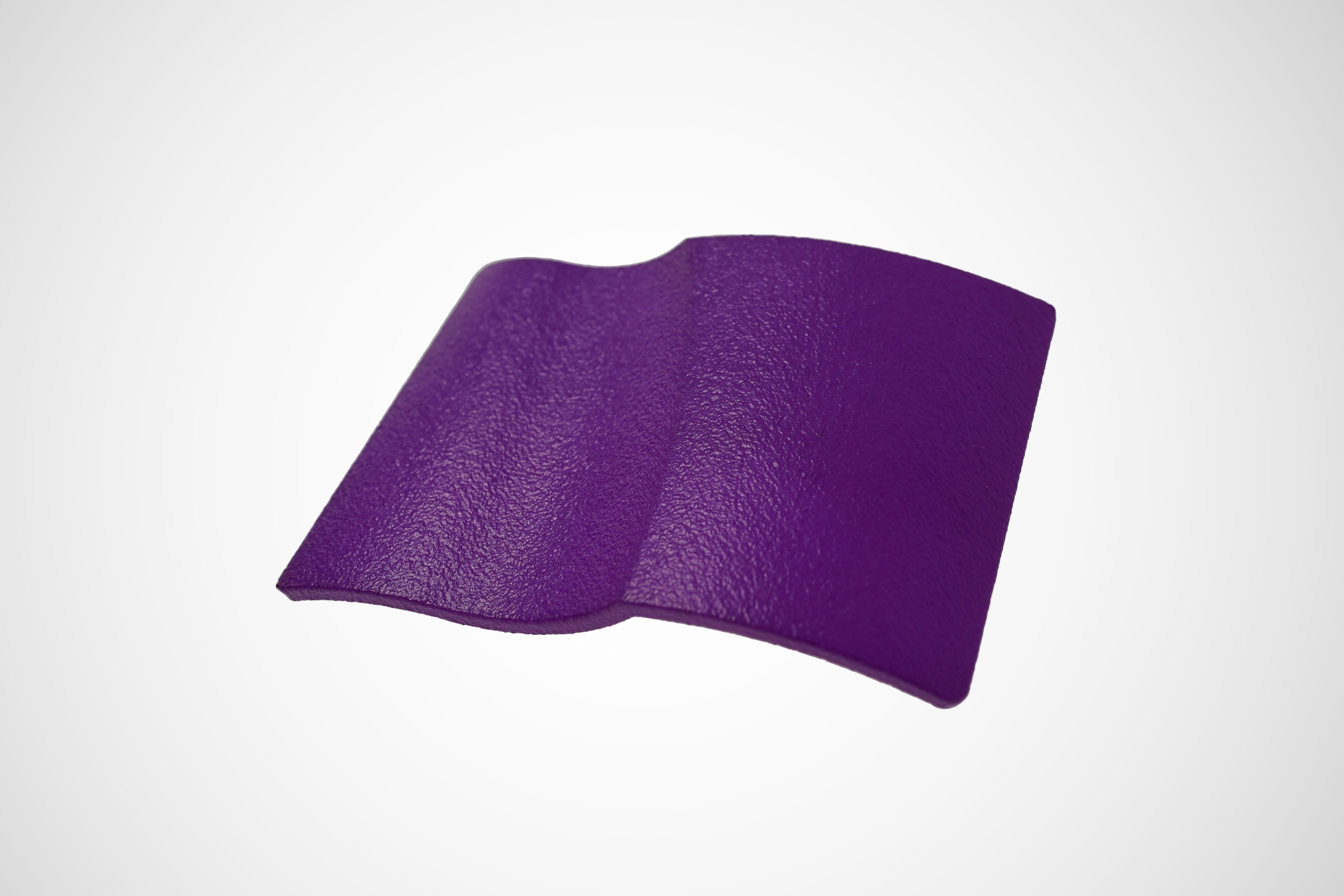

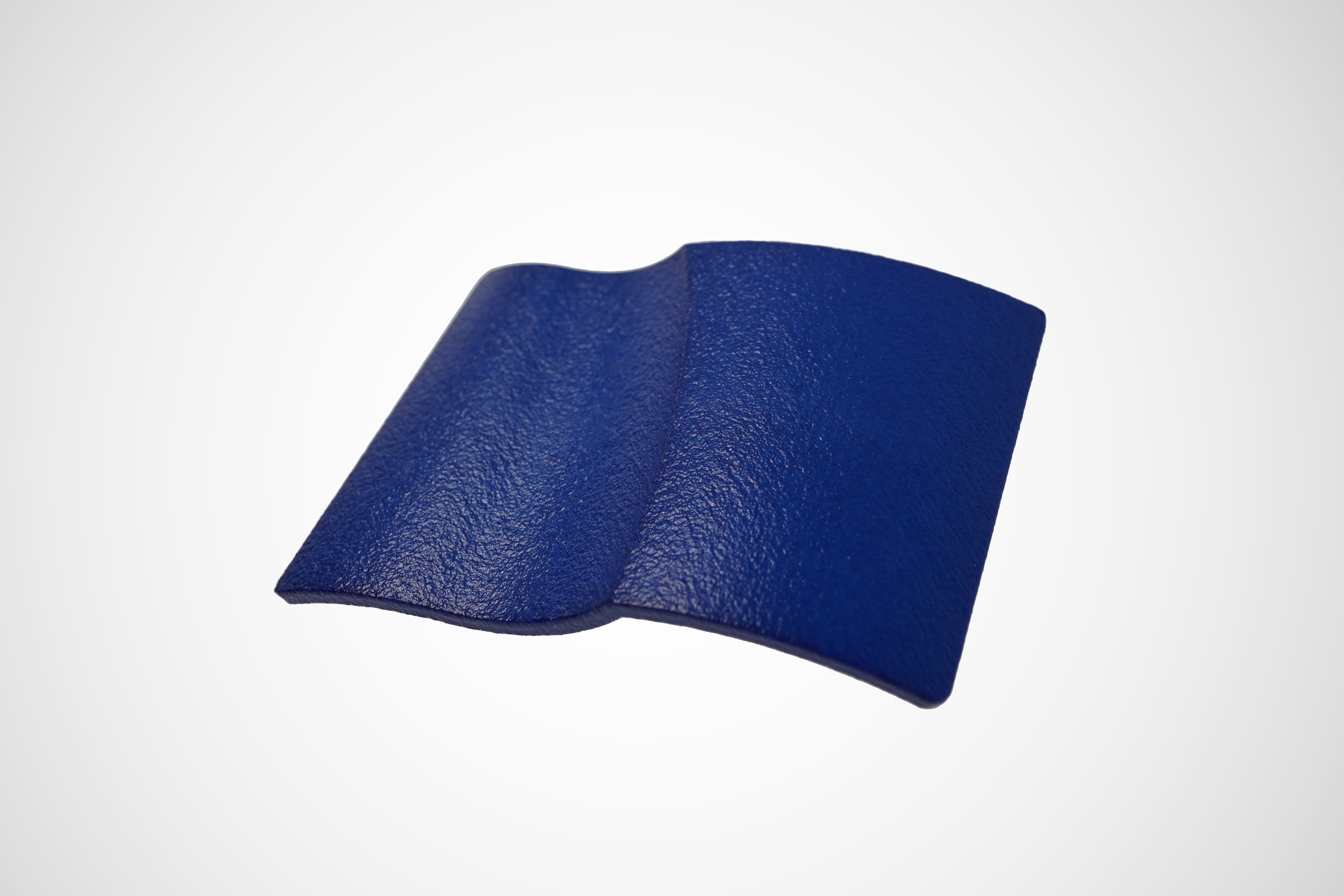

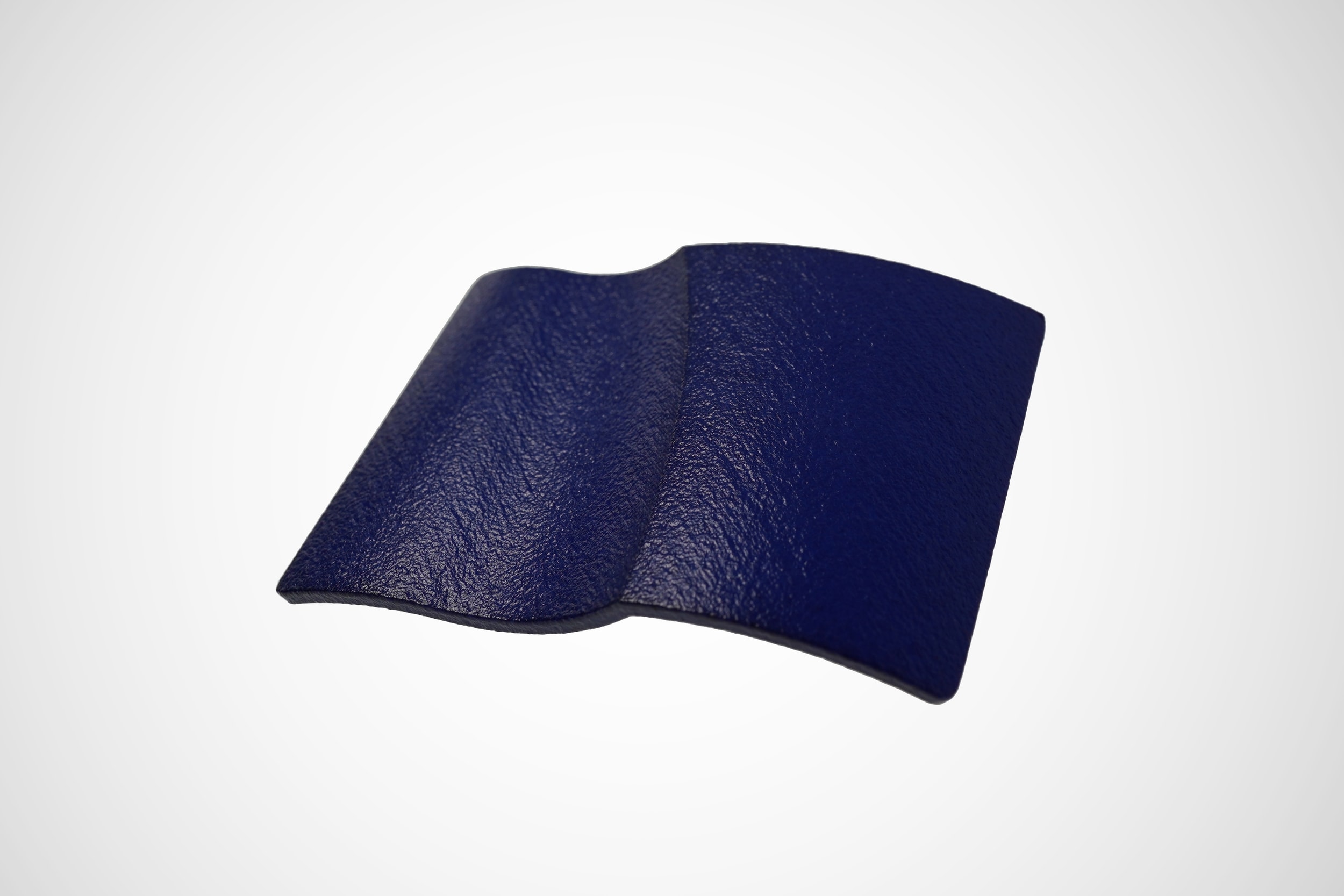

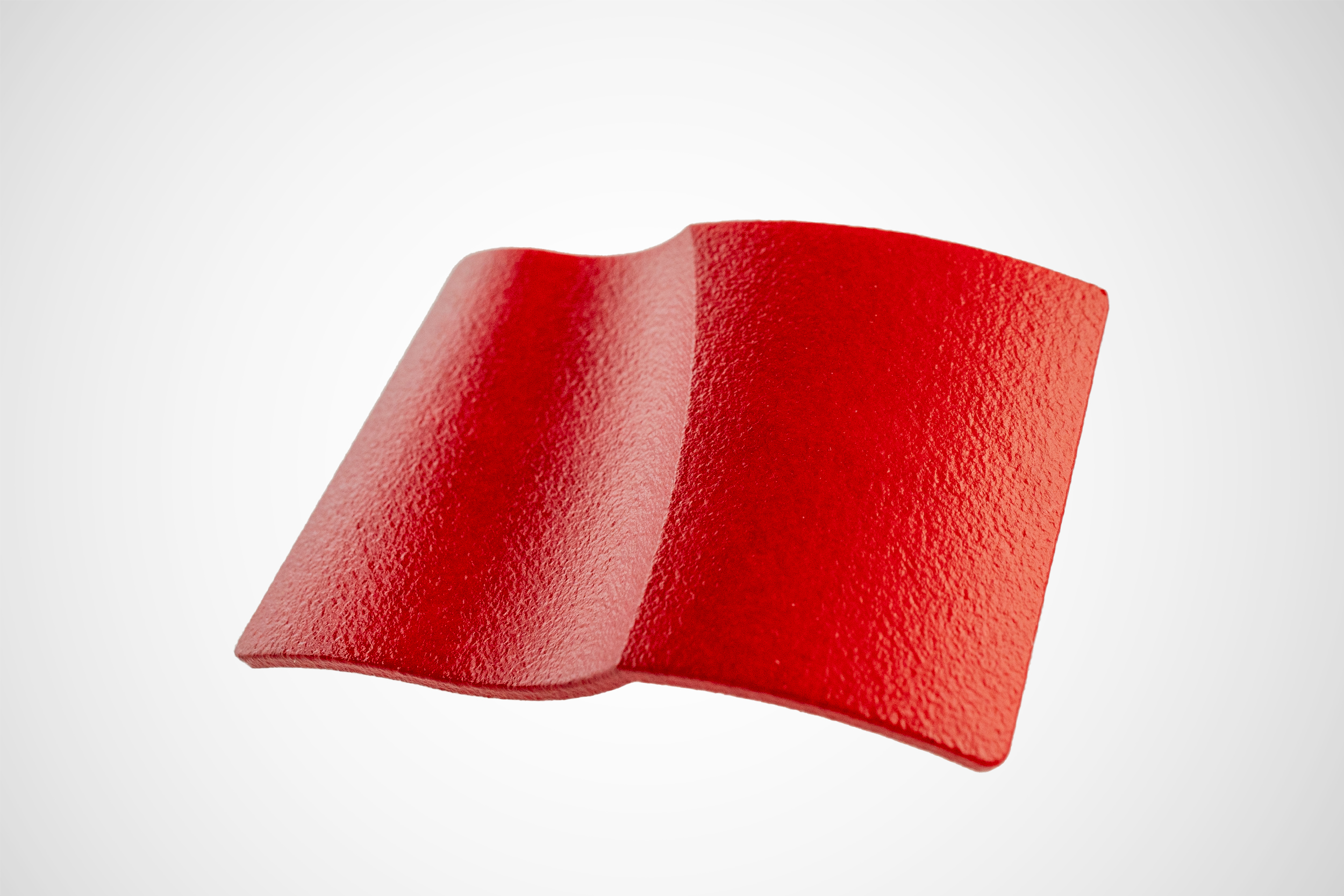

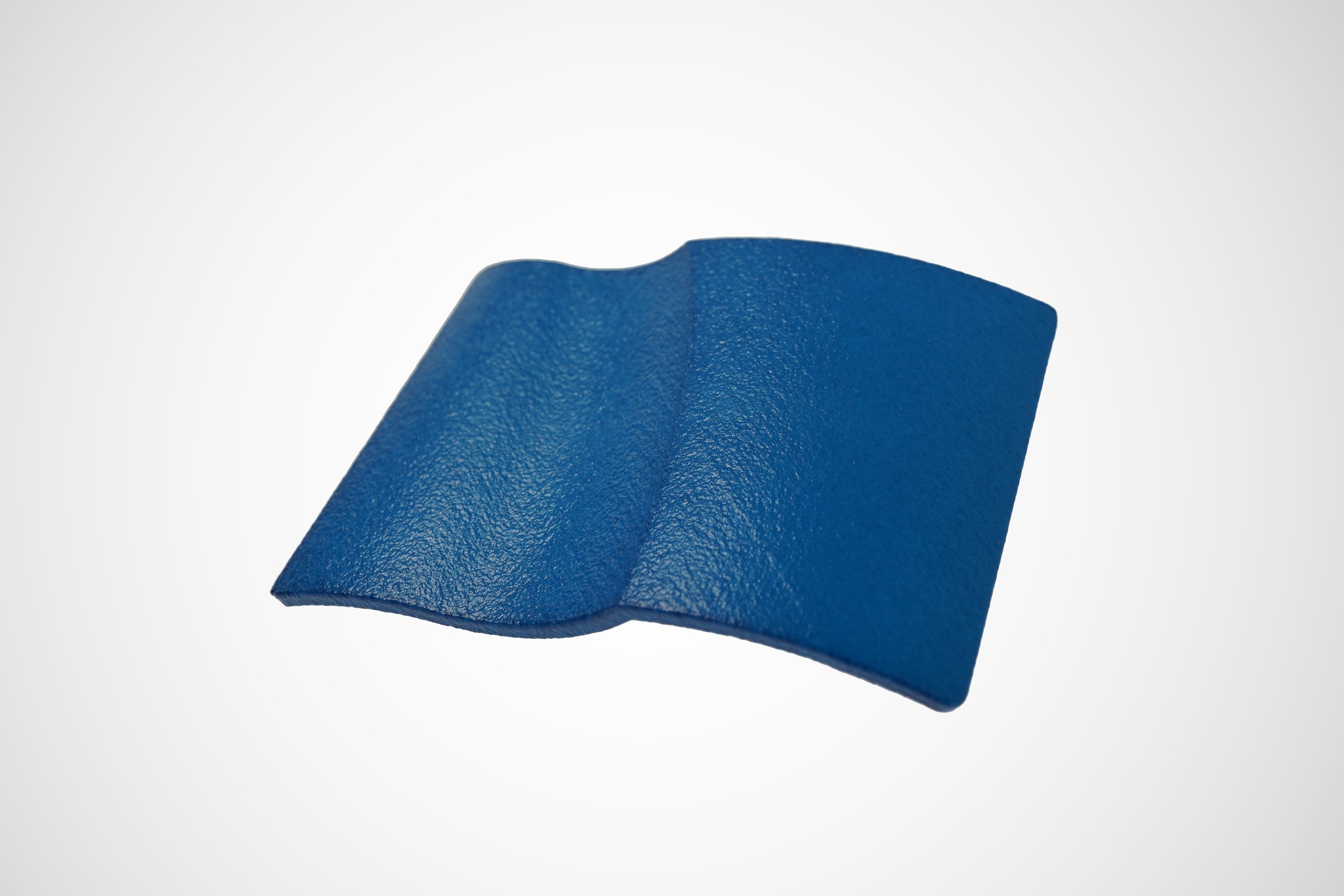

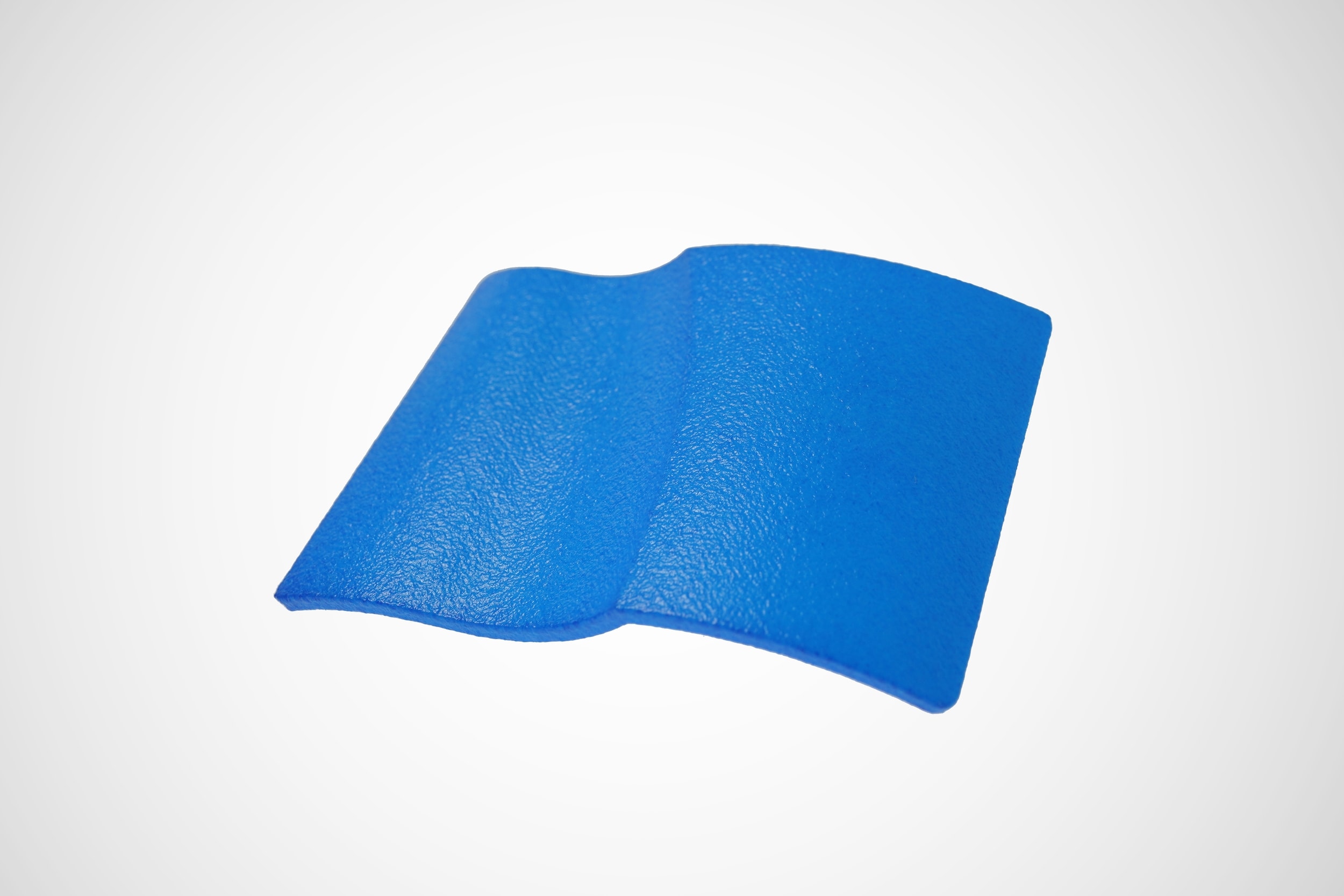

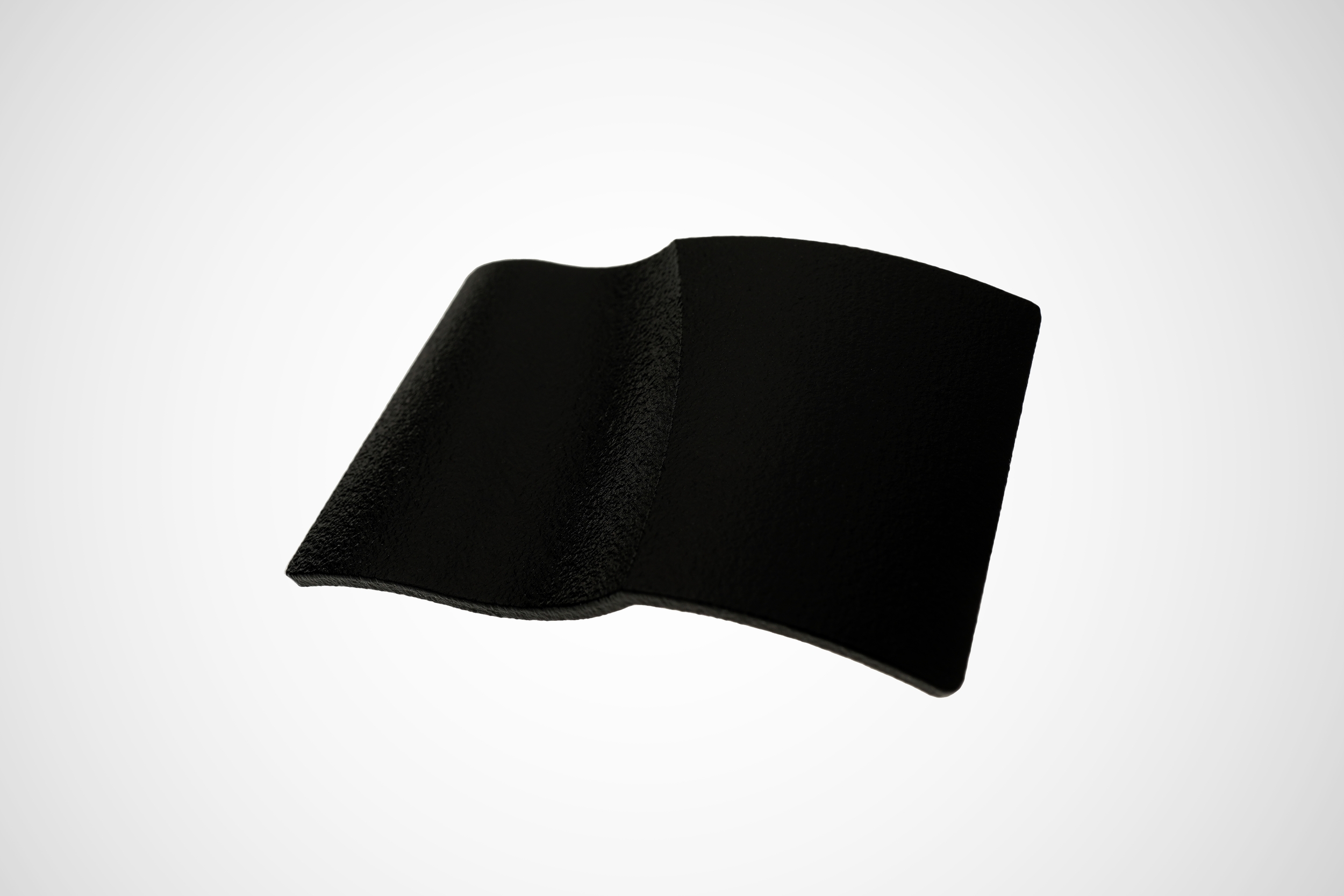

- reduction of surface roughness

- better mechanical properties

- color enhancement

- dirt resistance

Technological specifications

| Maximum part´s dimensions | 590 x 290 x 260 mm |

| Compatible materials | PA2200, PA3200GF, HP PA12, HP TPU |

| Material roughness after smoothing | Ra 2-3 µm |