Key features

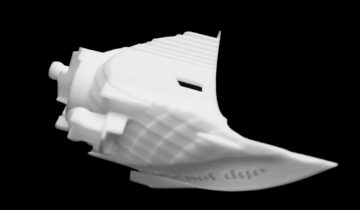

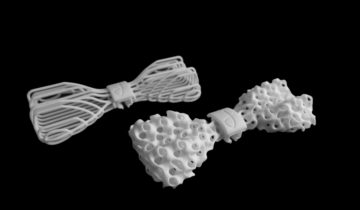

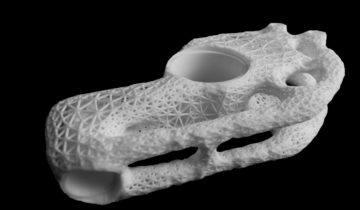

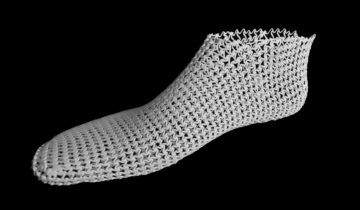

Nylon, as this type of plastic is commonly called, is the most widely used production material for SLS technology. This polyamide 12 (PA12) has a low density and is therefore lightweight. It has long-term stable properties and is characterized by good chemical resistance, high elasticity and strength. The raw part made of PA2200 is pure white

in color and can be easily colored by dip-dyeing technique.

Suitable uses

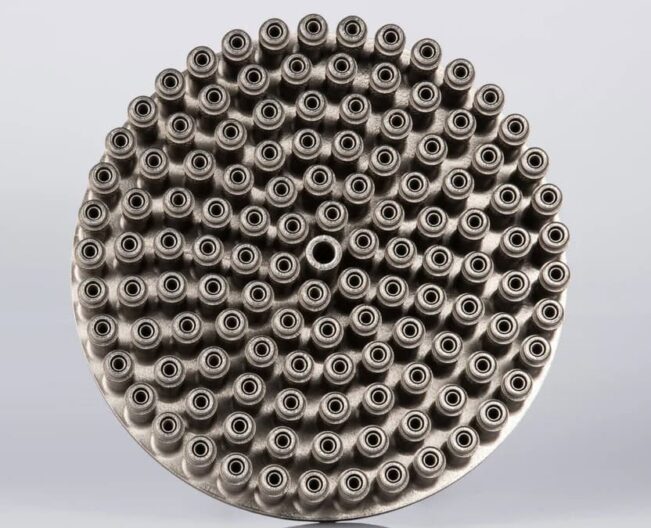

The versatility of nylon makes it a material that is often used in prototype, design,

test and assembly production. However, the PA2200’s balanced mechanical properties enable it to produce end-to-end functional parts, making it a suitable alternative

to injection molded plastics.

Specific applications

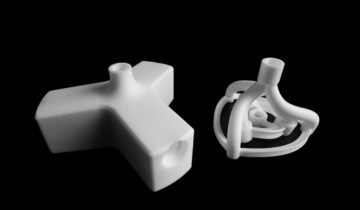

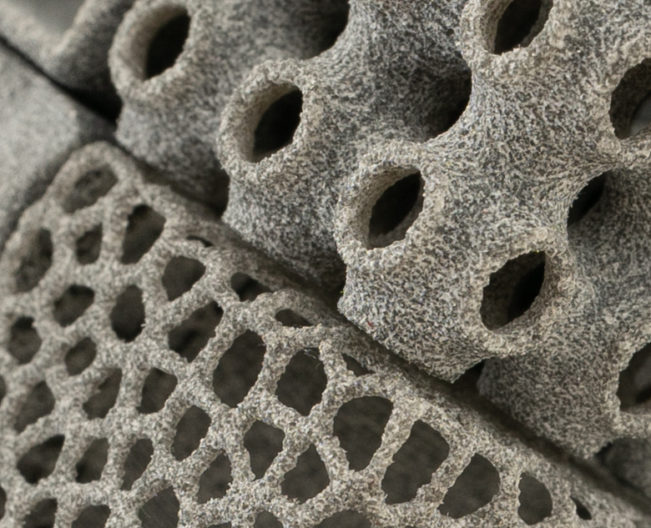

- assemblies of parts with flexible joints (snaps, clips, hinges)

- functional parts with active structures

- orthotic devices

Technological specifications

| Standard delivery time | 4 working days |

| Production accuracy | ±0.2% (with lower limit ±0.2 mm) |

| Production layer | 0.12 mm |

| Minimum wall thickness | 0.5 mm (maintaining properties 1 mm) |

Datasheet

| Tensile strength | 48 MPa |

| Modulus of elasticity | 1650 MPa |

| Elongation | 18 |

| Heat distortion temperature HDT 1.8 MPa | 55.1 °C |

| Heat distortion temperature HDT 0.45 MPa | 127.8 °C |

Download datasheet

Keep everything in one place. Download the datasheet of all our production materials.

Download datasheet