Better, faster, more powerful

Additive manufacturing of end parts will reduce your costs while allowing you to deliver products even sooner than your customers expect. It will shorten your supply chains, reduce the volume of material used, give your products new properties and help you meet emission limits. Are you planning to test additive manufacturing? Then we recommend switching to fast prototyping.

Series production

tailored to your needs

Does that sound like a dream of the future? It’s not. Additive manufacturing is already ideal for small batches, in which you can easily produce each piece with slightly different geometry and the cost will remain virtually the same.

Appropriate selection

of technologies

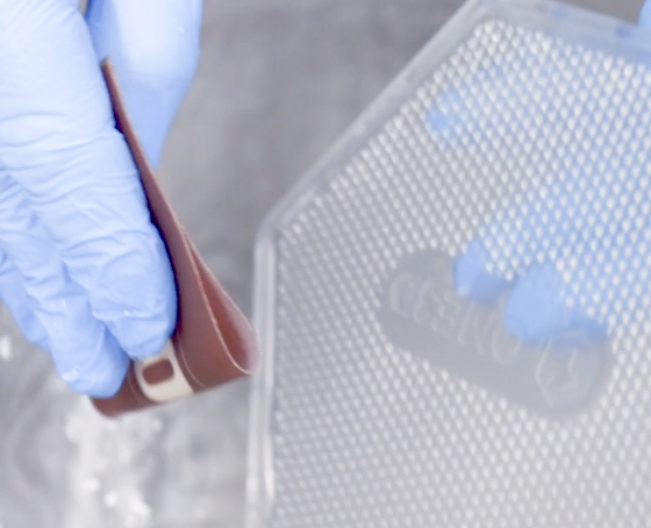

Combine technologies, materials and finishes until you are satisfied with the result. We will be happy to help you choose exactly what you need.

Certified

quality

We are the only ones in the Czech Republic with ISO certification for additive manufacturing of plastic and metal, so you can rely on us to produce your products always in perfect quality.

4 reasons to use additive manufacturing for end products

The complexity of a part does not necessarily determine the price

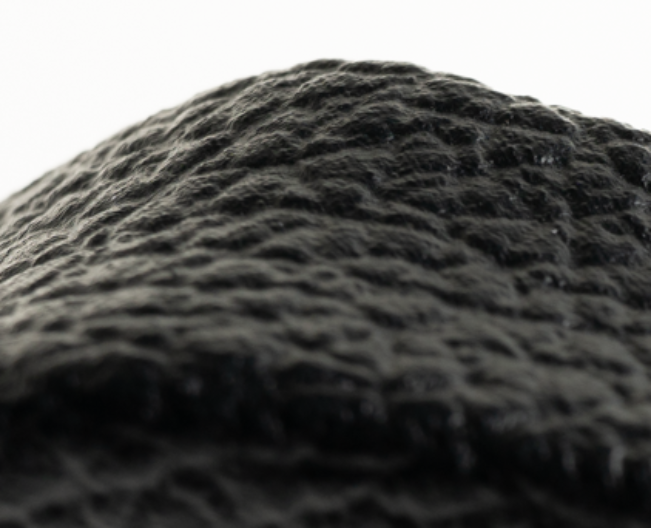

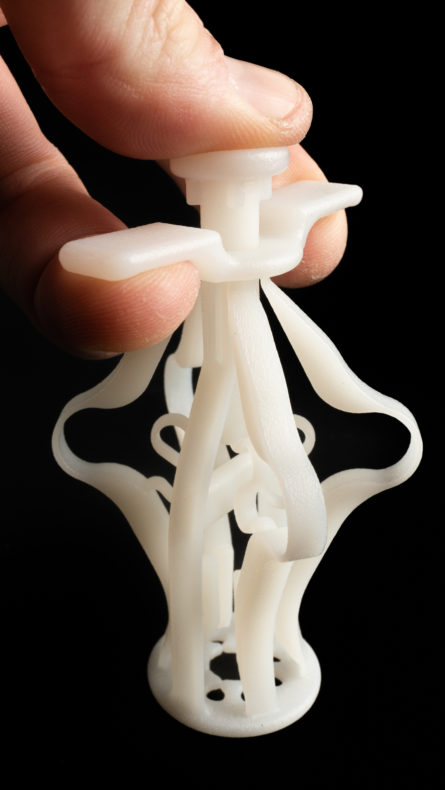

You can be very free in designing the geometry. The limitation is only your own imagination, as the complexity of the parts is not strictly linked to the cost per piece.

Your product can have superpowers

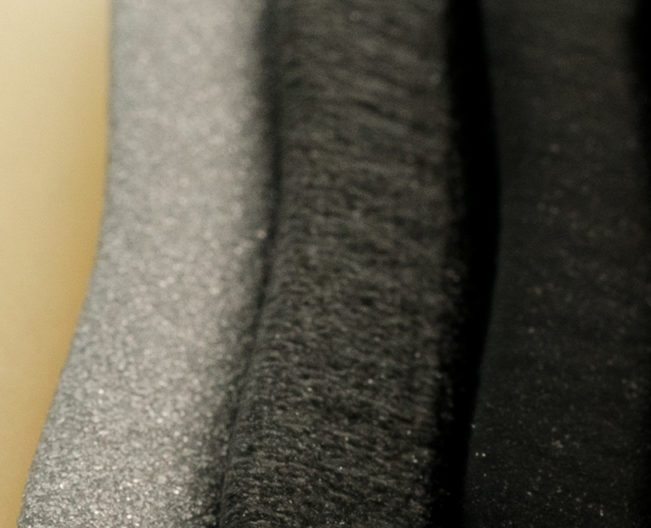

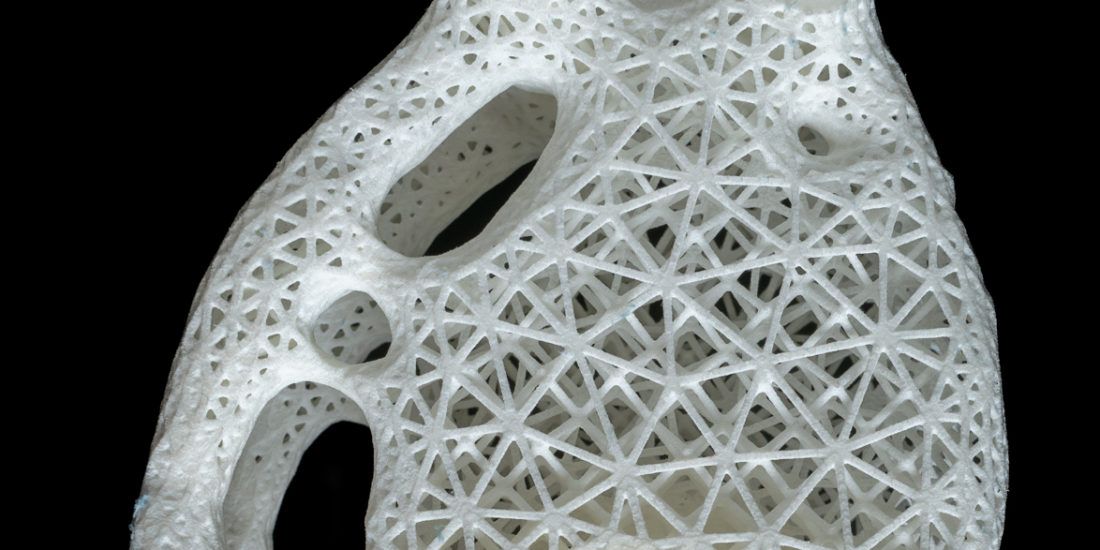

Flexibility, lightness, rigidity, durability During topological optimization, lattices of structure and organic design are naturally created to give your parts unique properties, an organic appearance and reduce weight.

Production flexibility lets you experiment

Not only can parts be flexible using timeless geometry, but your development can be flexible as well. Additive manufacturing is very fast compared to conventional technologies for piece and small batch production.

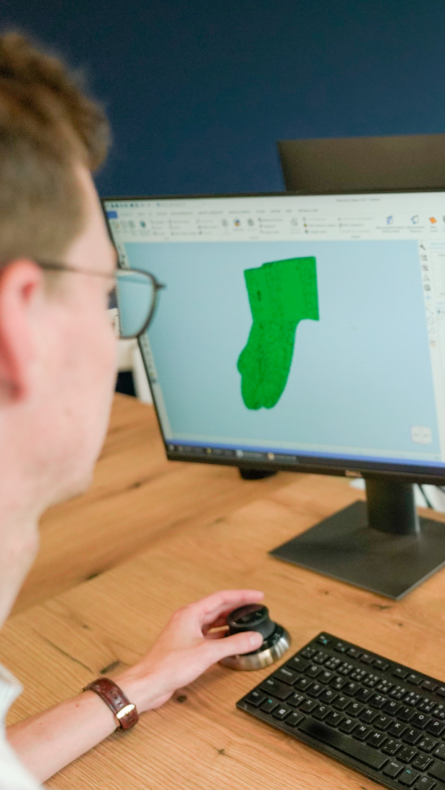

Changing the design takes just a few mouse clicks

You don’t need any mold. Just edit the 3D model in CAD and you can make any shape. Simply change the digital data according to your needs.

Společně tvoříme

nová konstrukční pravidla

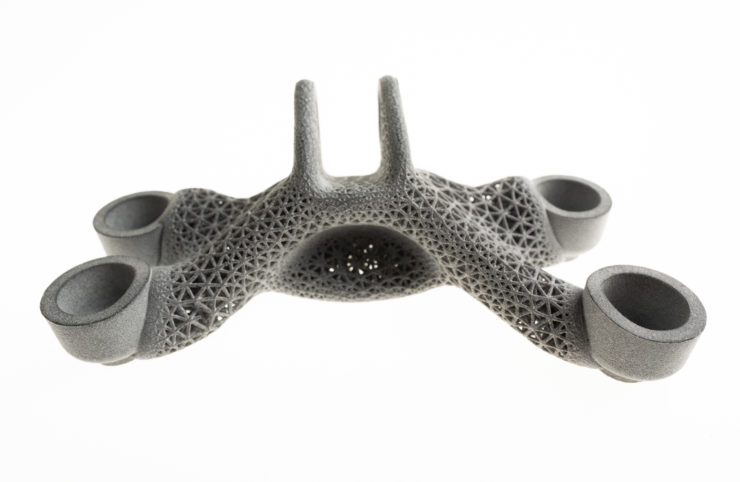

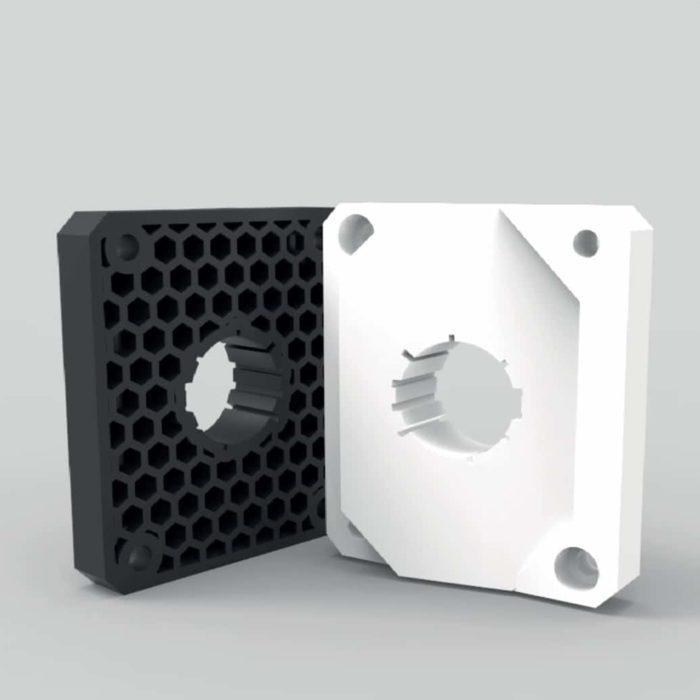

Costs half, weighs a tenth

Using the honeycomb structure and the additive technology SLS, we have reduced the cost of the mounting blocks and eased the work of the press operators.

Zjistit více

Artistic tribute consisting of algorithm, stainless steel and garnets

We helped the experimental goldsmith Zdeněk Vacek win at the Designblok 21 festival and pay tribute to his mother’s lifetime work.

Zjistit více

Details are important

We produced detailed 1:400 scale models of buildings, including spacious parking lots, trees and even the smallest details.

Zjistit více