What is it?

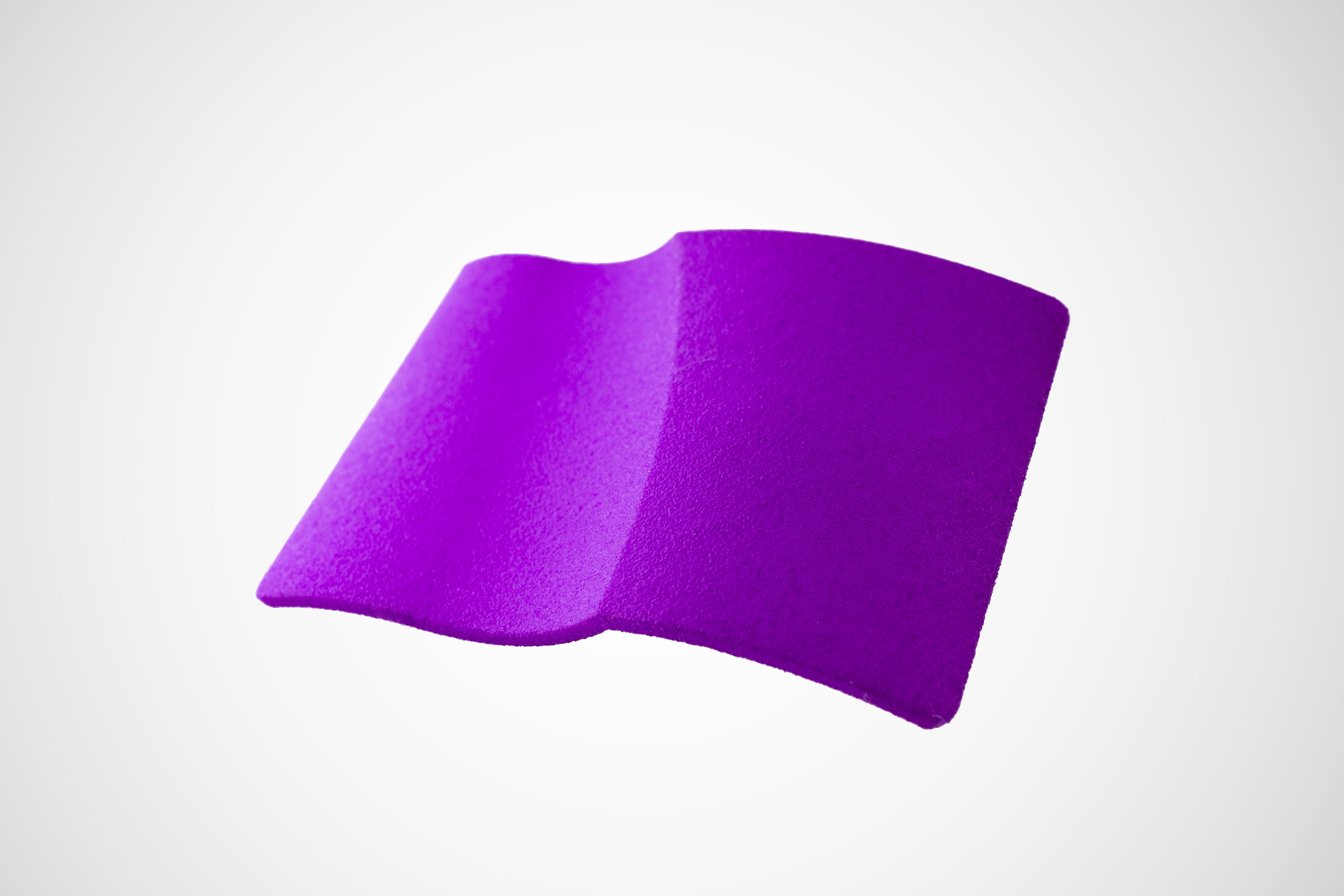

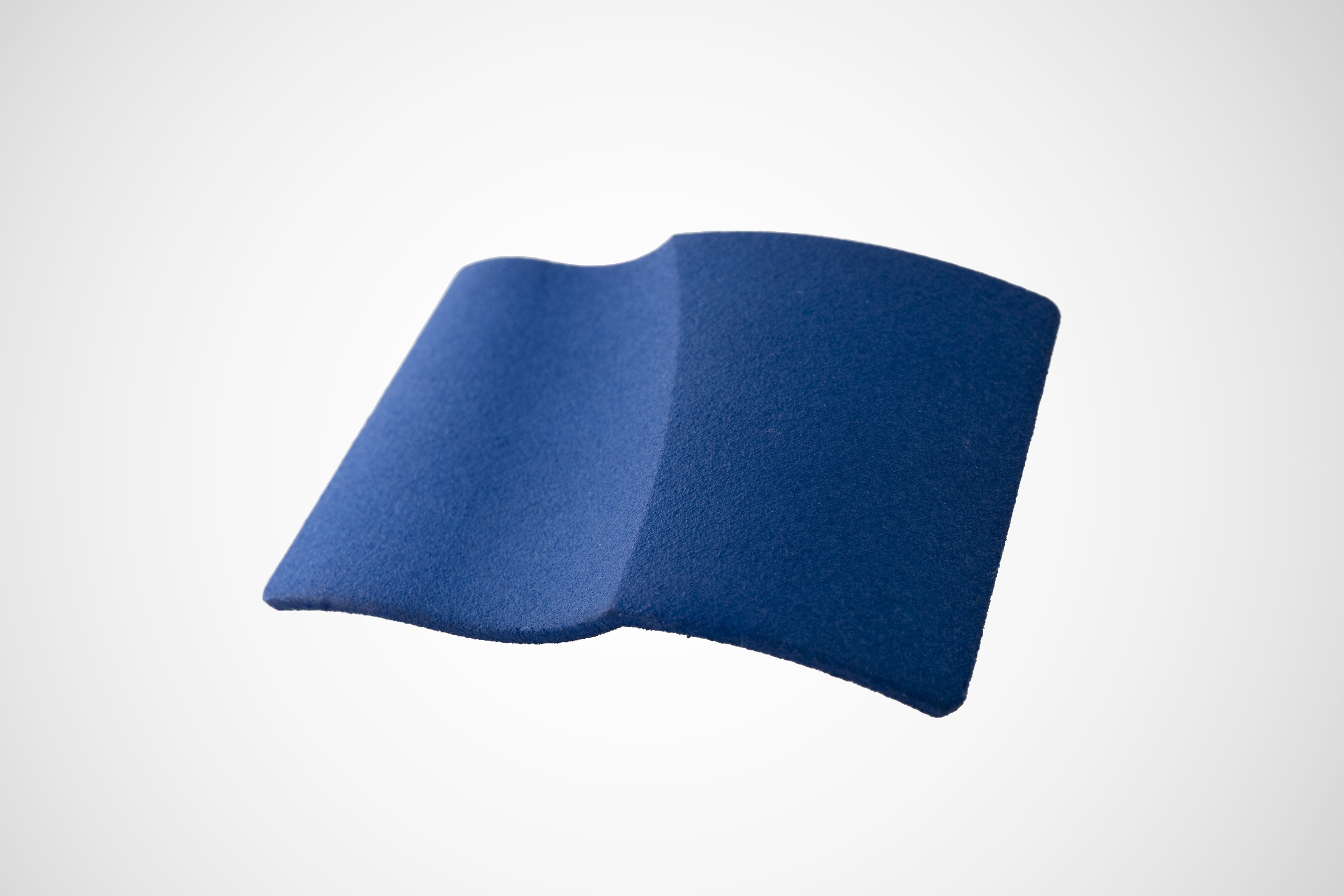

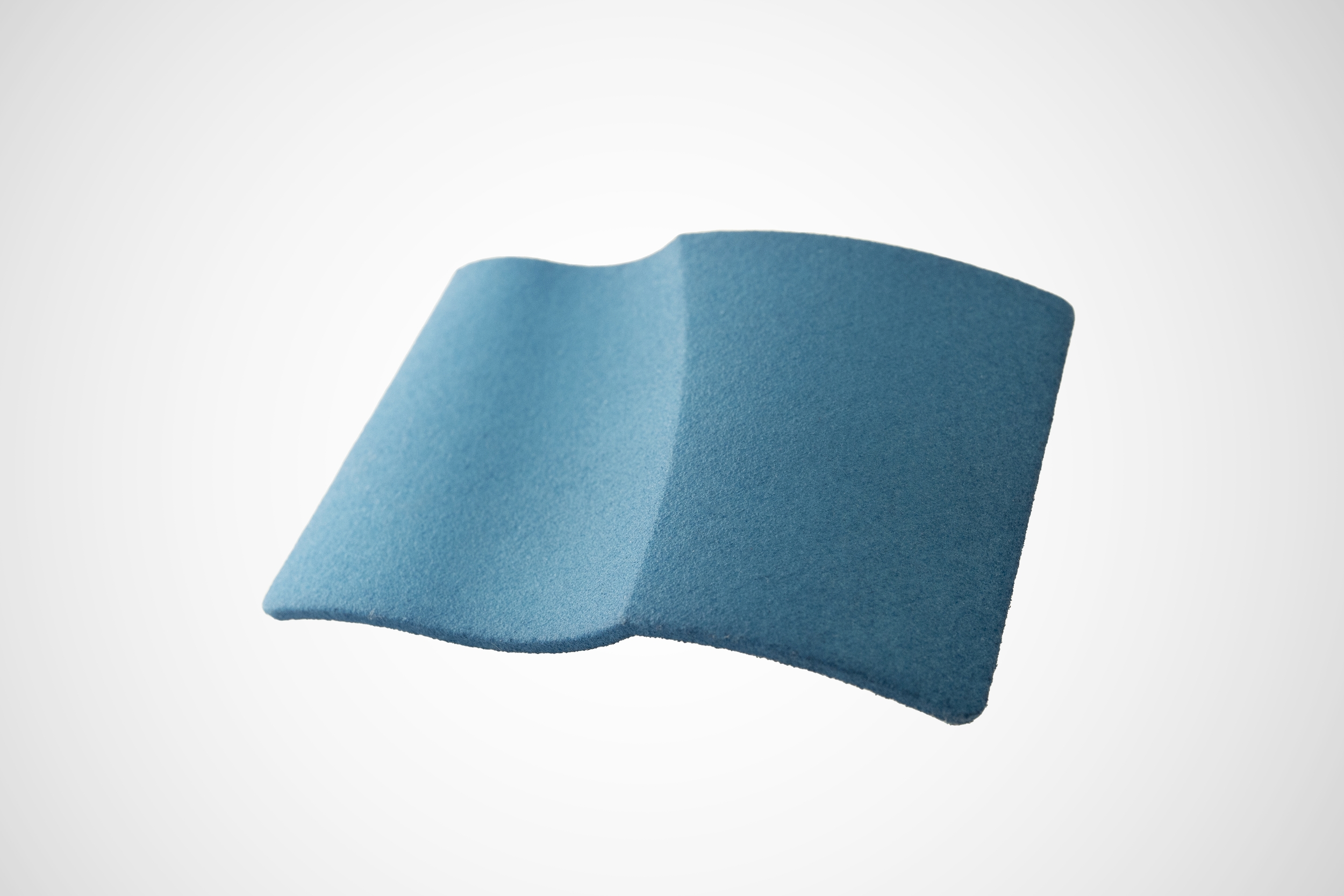

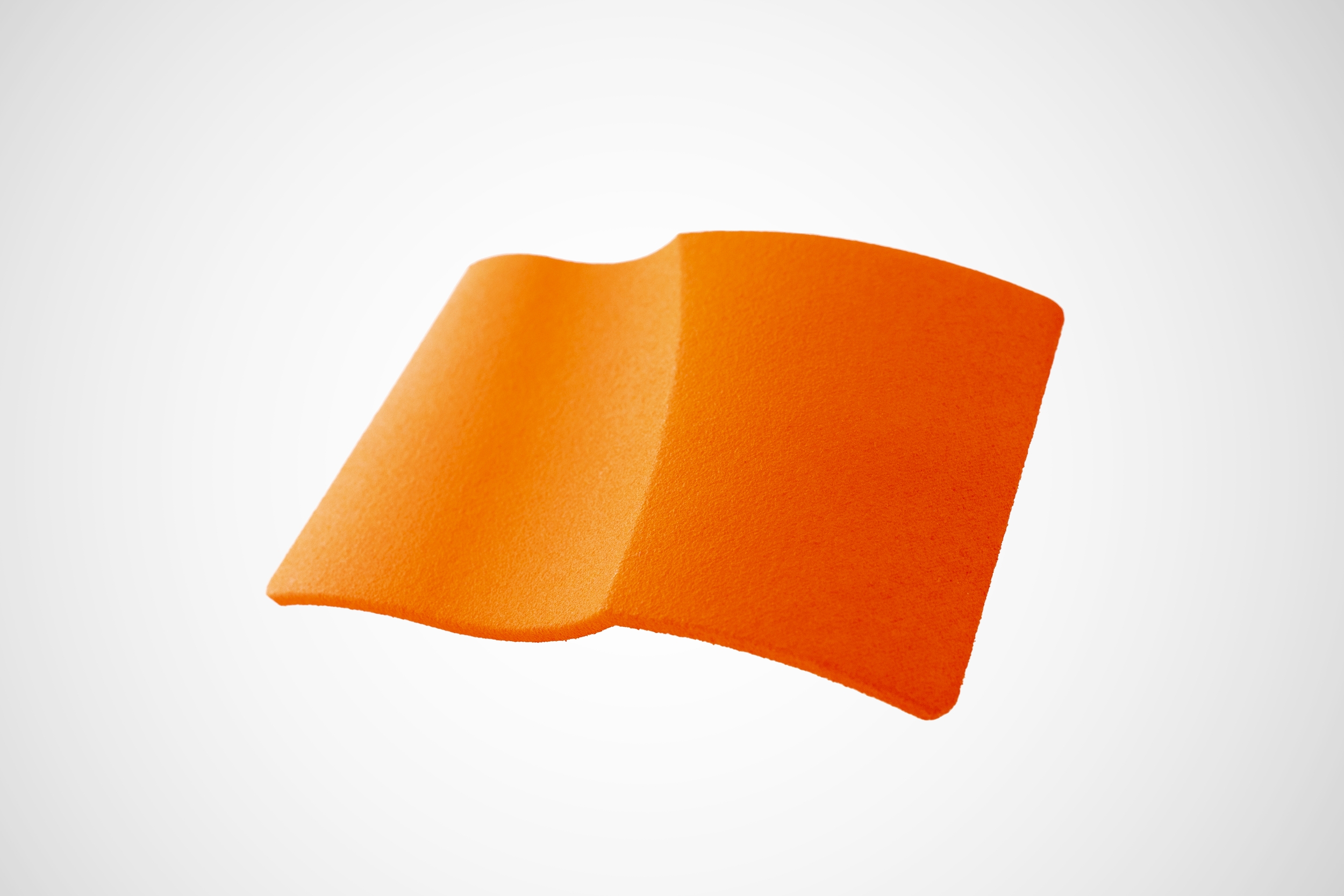

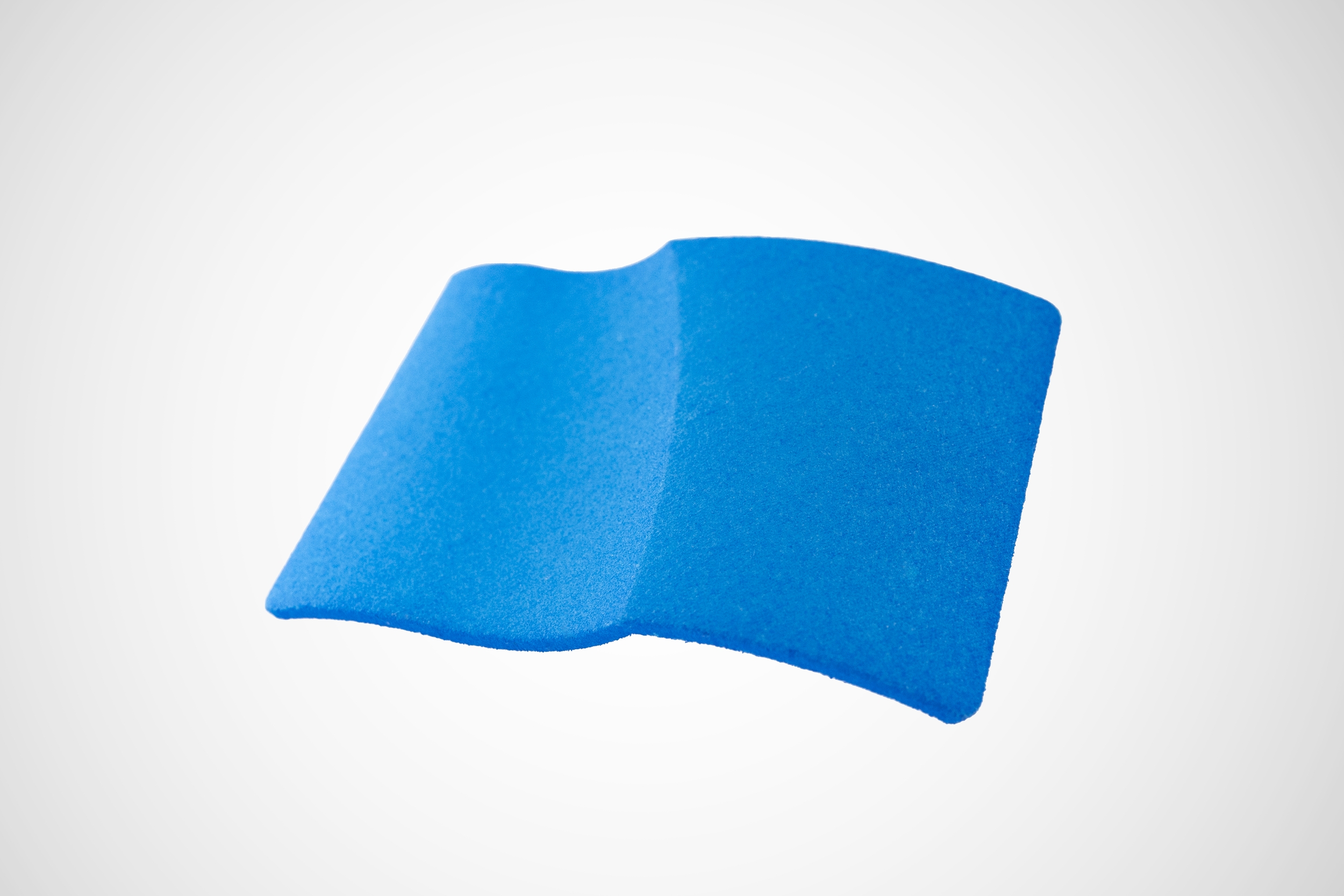

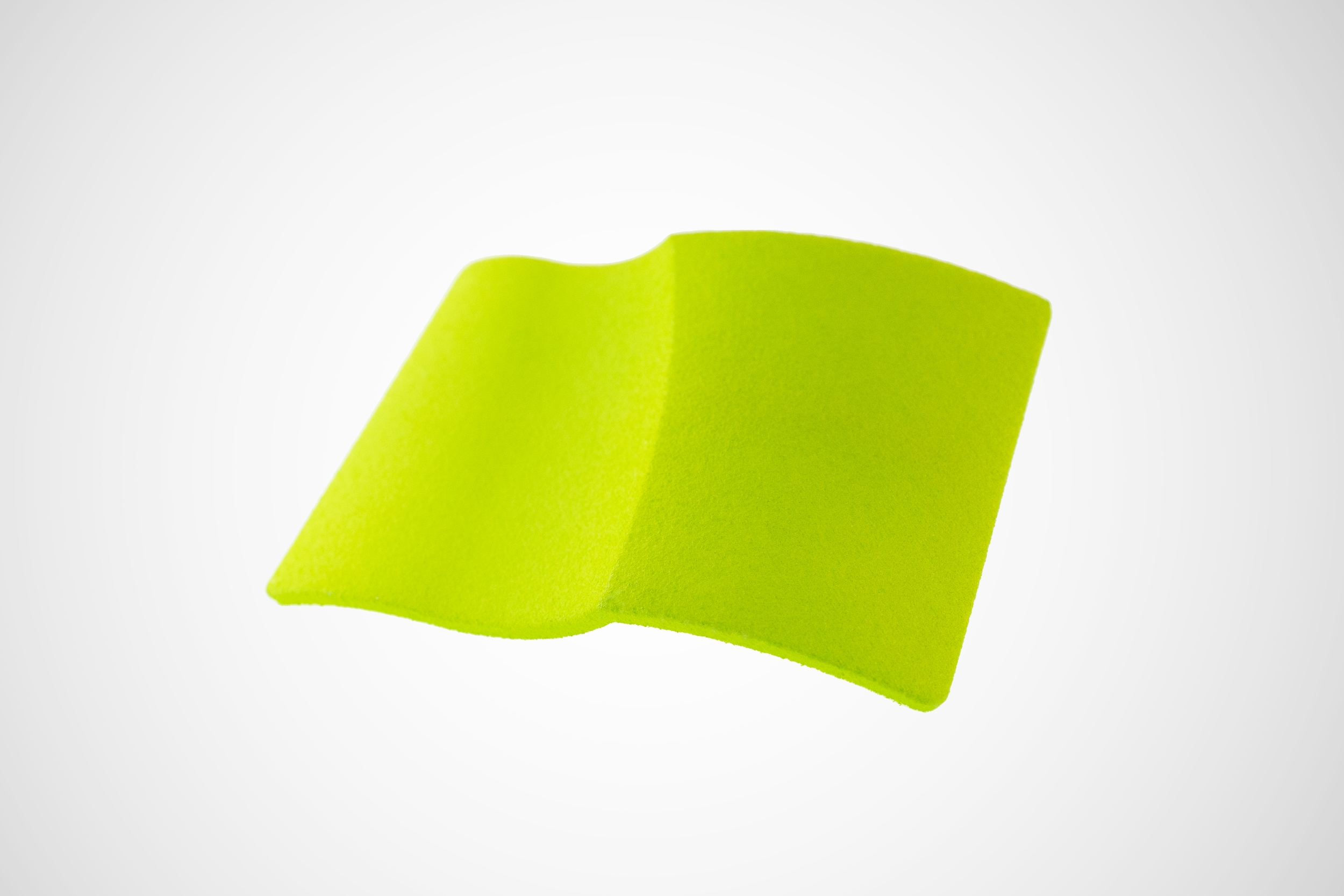

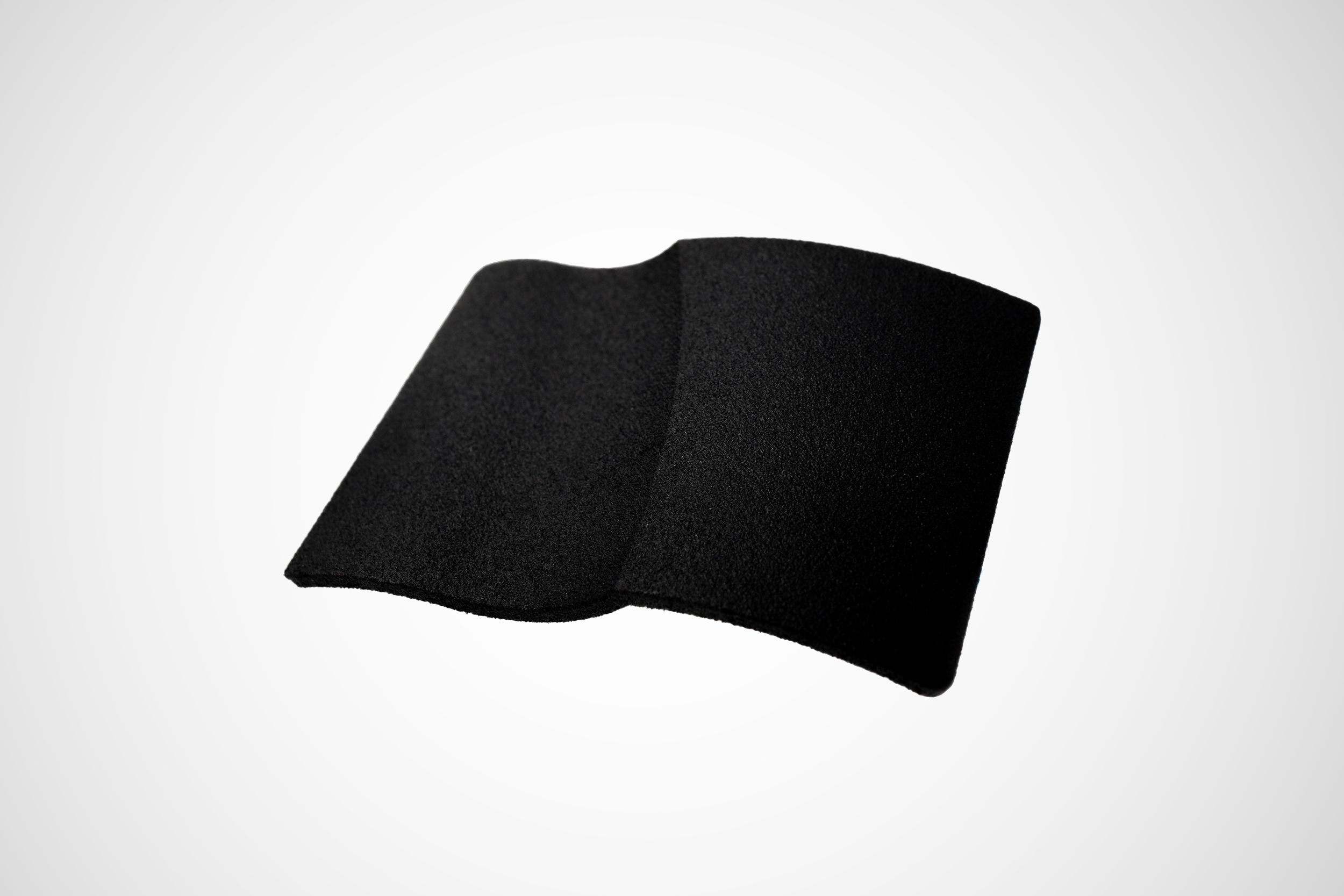

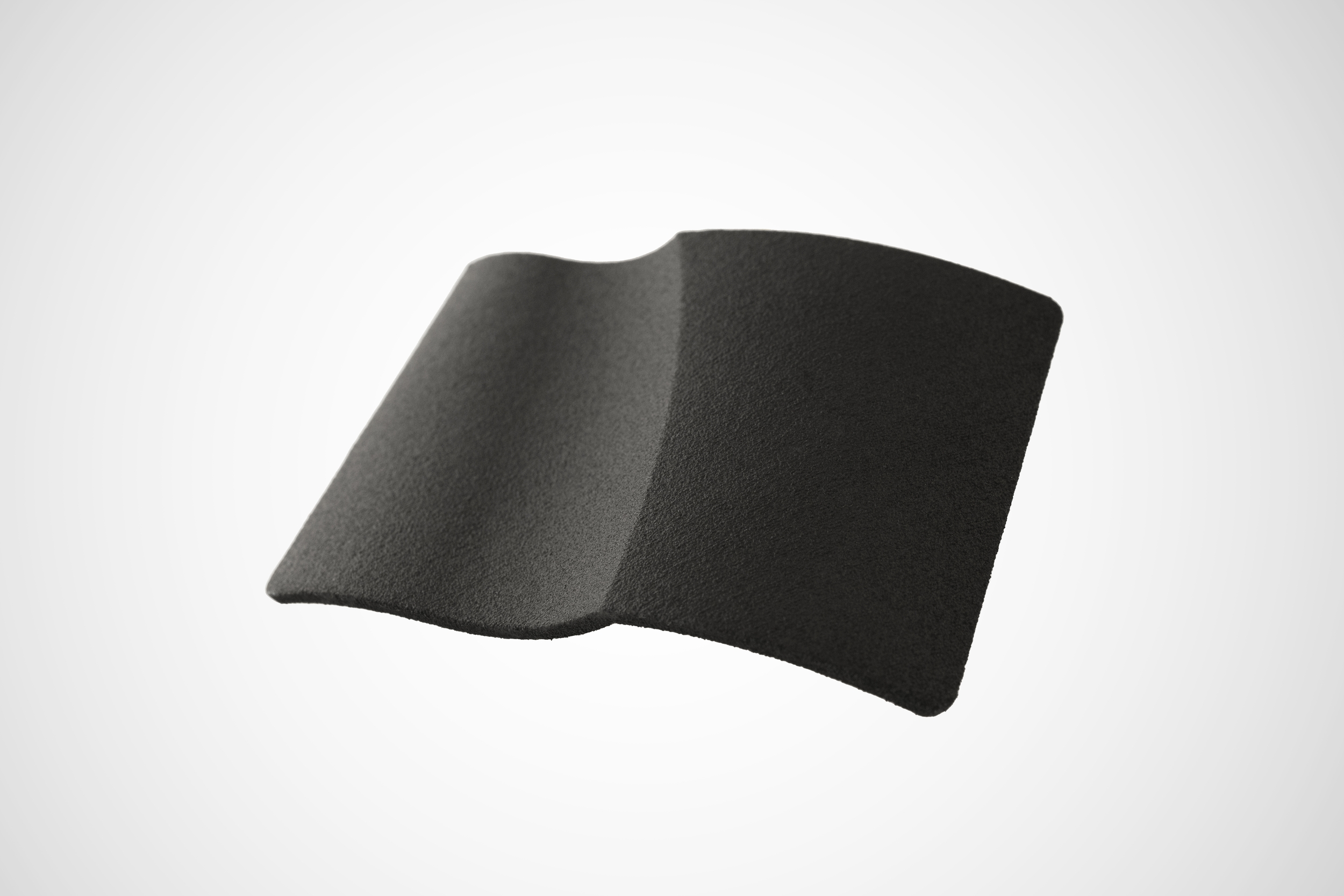

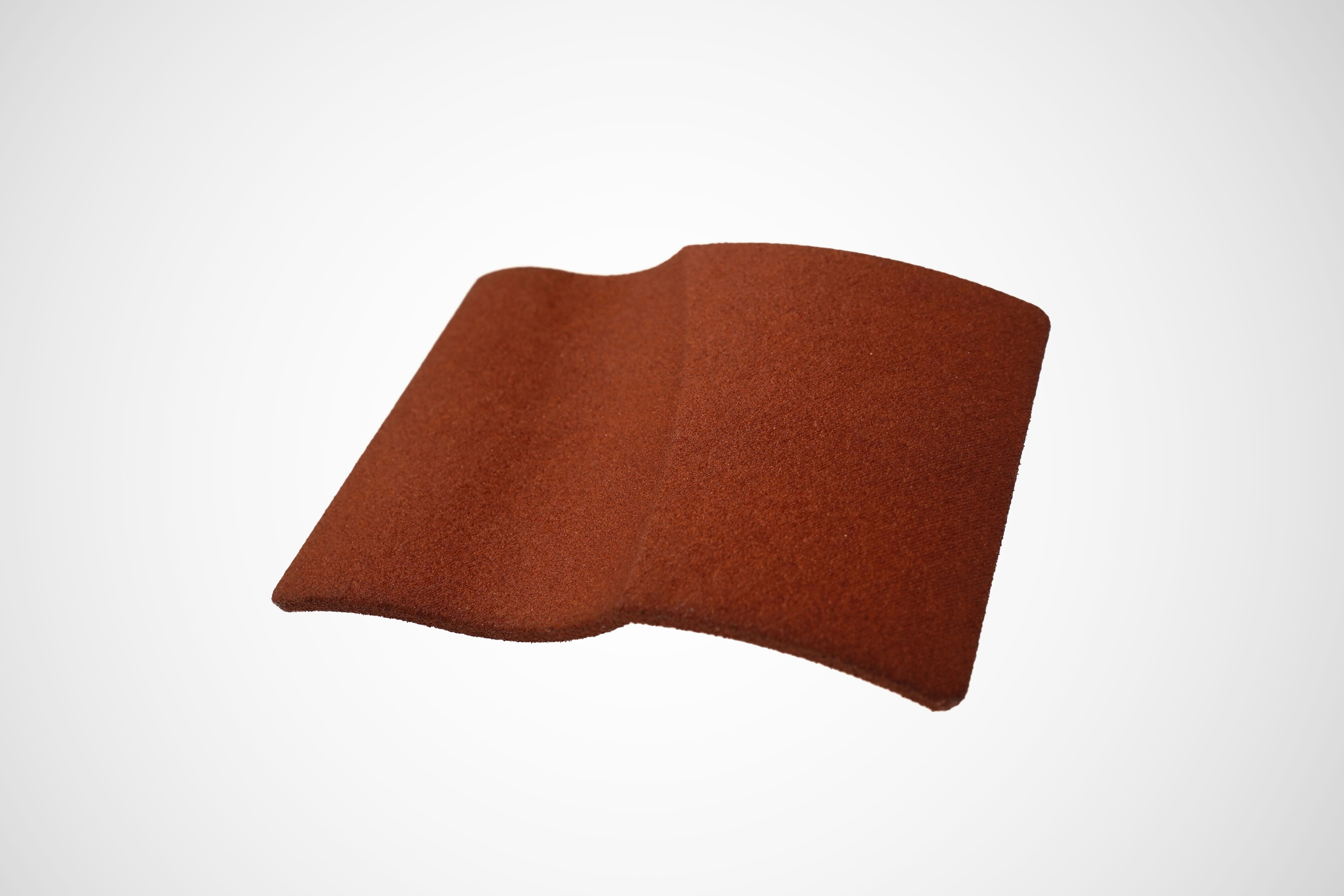

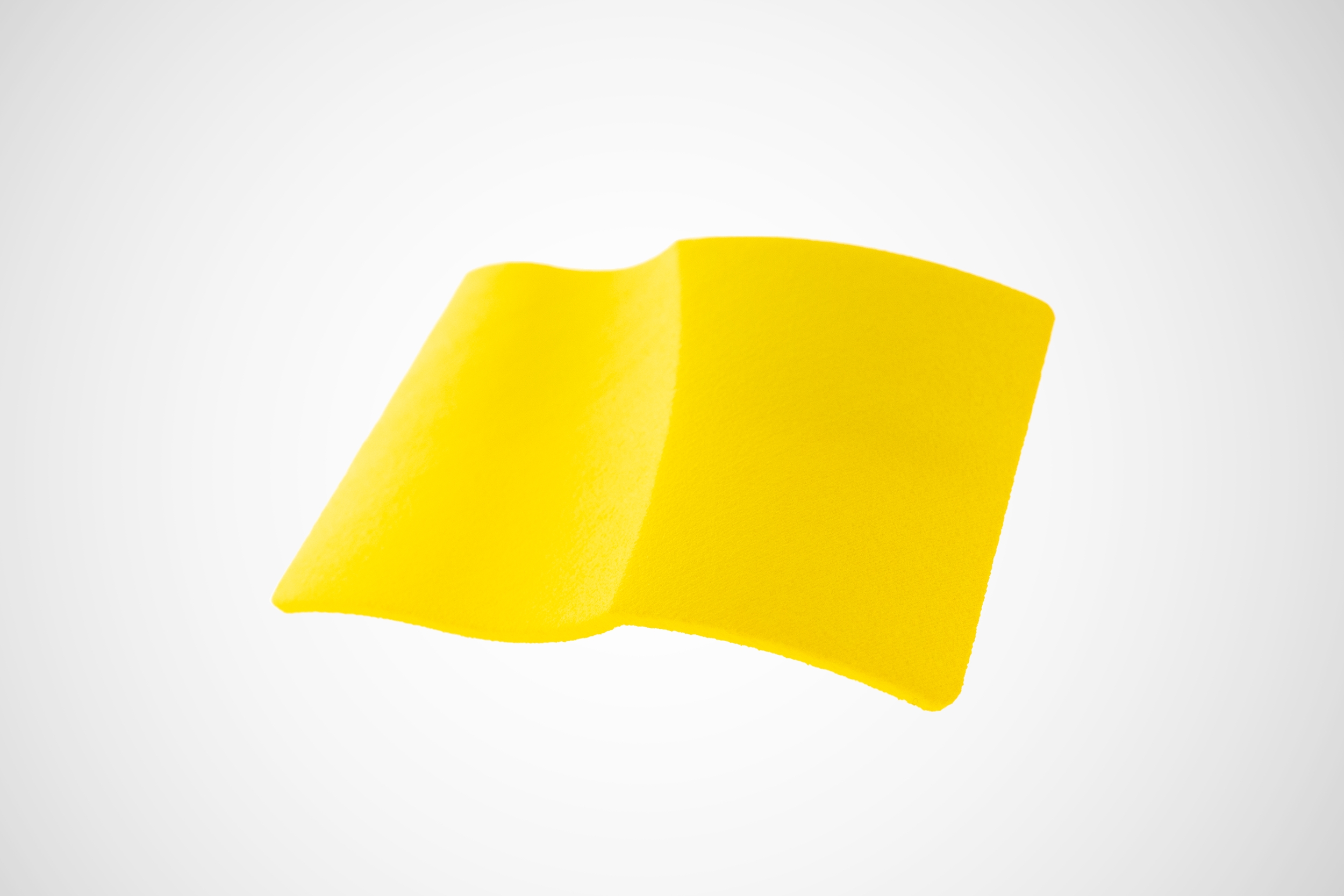

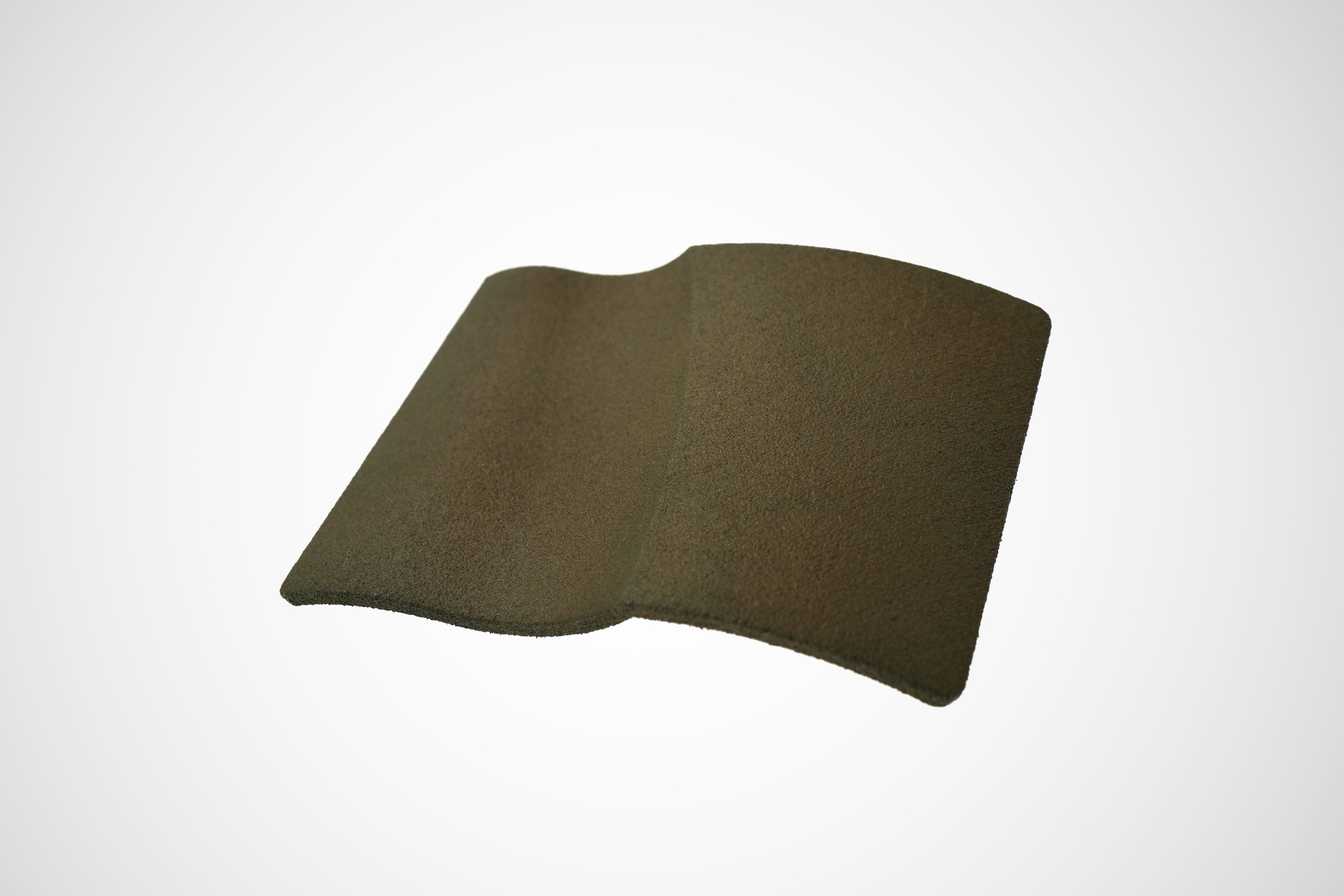

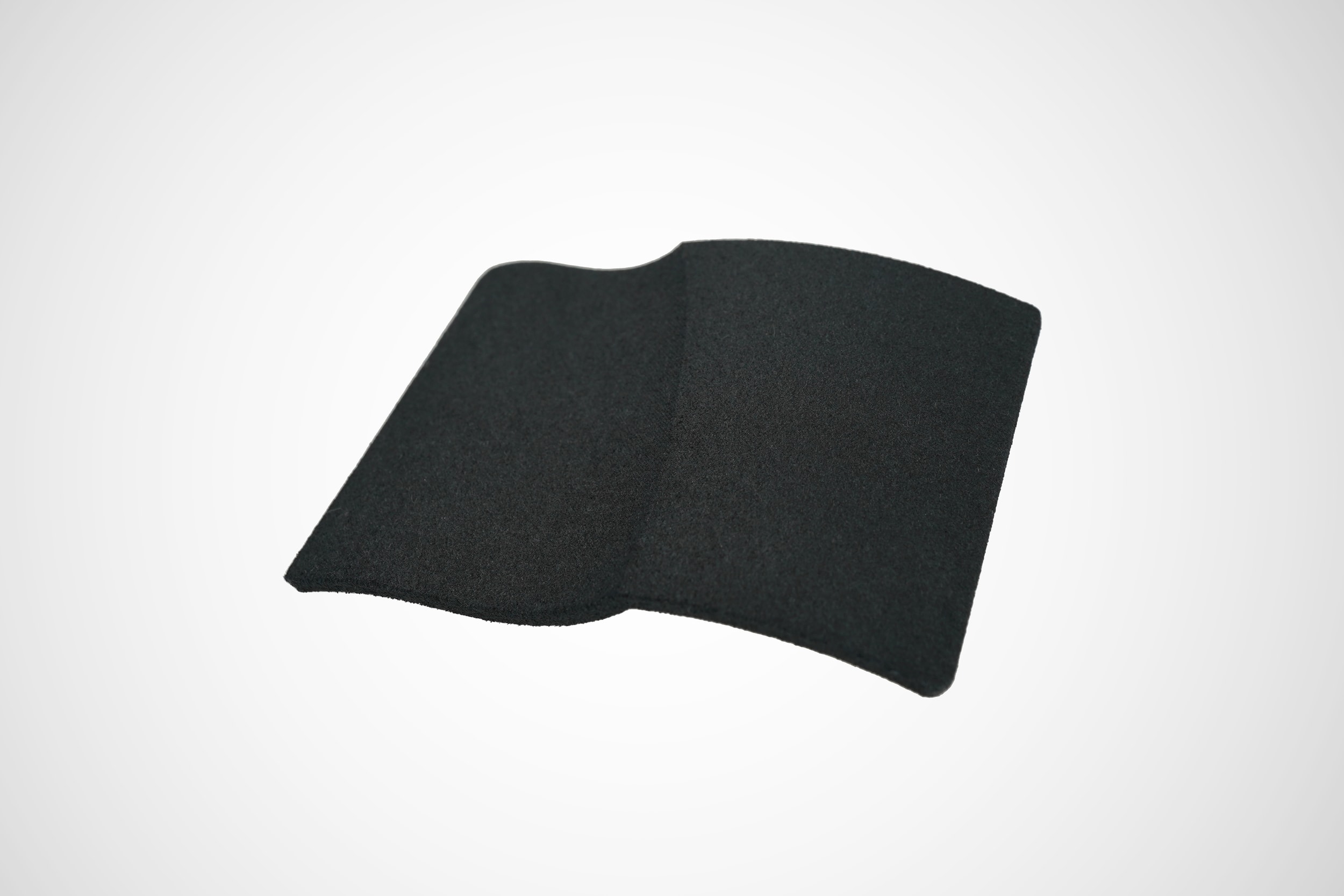

Thanks to this technology, the parts can be coloured in hard-to-reach structures

and surfaces.

The dye, in which the product is immersed after thorough cleaning, penetrates

the surface of the material to a depth of several tenths of a millimetre during dipping.

The parts are finally cleaned of dye residue and carefully dried.

What is it used for?

It is advisable to choose dip dyeing for parts that require high resistance to paint abrasion.

This post-processing can be a final surface finish or precede chemical smoothing,

for example.

Main advantages

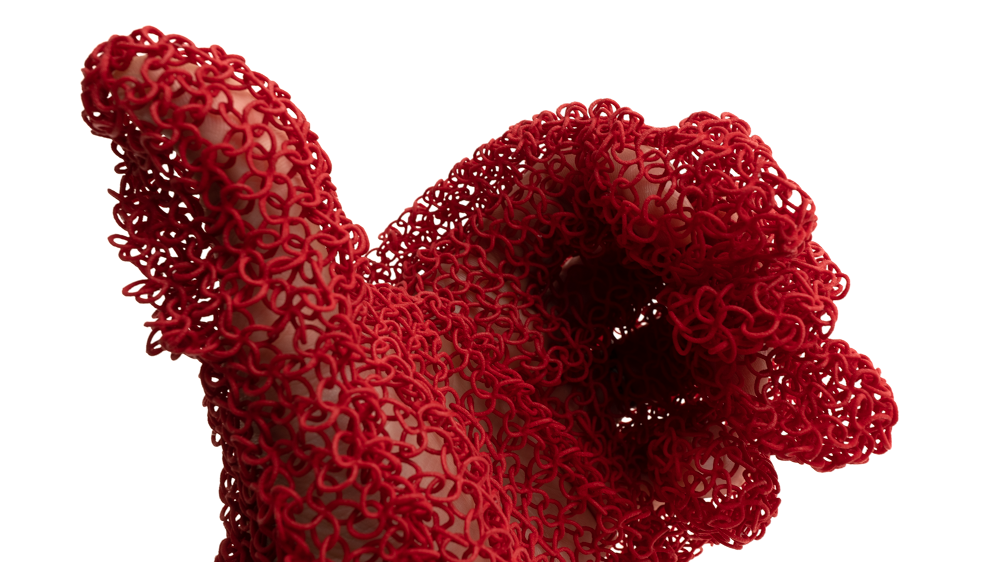

- coloring of structures and parts that cannot be painted

- color is excellently resistant to abrasion

- time-saving coloring method compared to wet coating

Technological specifications

| Maximum part size | Ø 450 x 430 mm (in case of larger dimensions, on request) |

| Number of base shades | 22 |

| Compatible Materials | PA2200, PA3200GF, Waterclear, HP PA12, HP TPU |