Challenge: Quickly deliver a prototype of a part on the basis of a proposed design that matches the characteristics and appearance of the final product.

Solution: Producing a prototype from 2 different materials that meets the parameters of a two-component (2K) part.

Impact: An additively produced prototype means significant financial savings over the conventional injection molding process. This would require mold production, suspension of the production machine including its adjustment, and in case of a non-compliant result, repetition of the entire costly process. For additive manufacturing, all you have to do is adjust the input data.

Result: Winning the tender and deploying a new version of the part to mass production.

Service: Rapid prototype production

Material: PA2200 and PEBA2301

Technology: SLS, Post-processing

It Mustn’t Crack Again

VW Group Škoda Car sold over 1,000,000 of its cars in 2020. In these cars the air distribution system is found between the engine and the dashboard, and it was high time for a change. It happened too often that this part would rupture during installation on the assembly line, both delaying the assembly process, and creating a large number of damaged parts and thus unnecessary material loss.

Two are better than one when they function as one

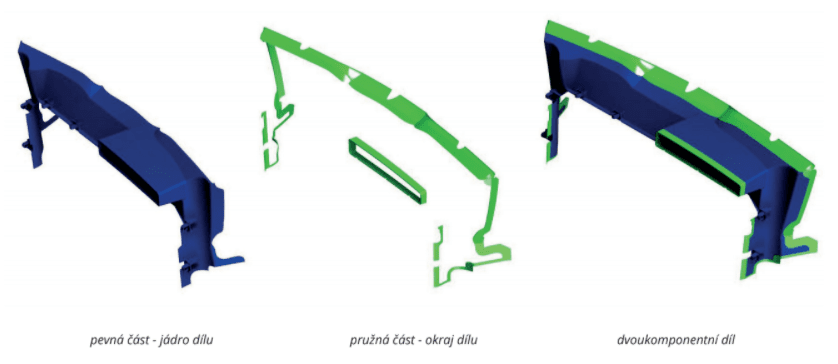

The main cause of this situation was manufacturing this part out of one material. The perimeter wasn’t very flexible, and this is where the damage occurred most frequently. So Škoda engineers came up with a design for a new part that has a thermoplastic rubber area on the seating surface. This creates a flexible connection of this critical part. Even though there are two parts, they need to behave as one for purposes of air tightness and strength. This was an ideal task for additive technology.

Design of the entire air distribution system out of nylon and thermoplastic rubber

Design of the entire air distribution system out of nylon and thermoplastic rubber

Design on Monday, prototype on Friday

The invitation to tender suited us perfectly. We have a great deal of experience with rapid prototyping and post-processing. We knew that we could produce the requested part quickly and with such quality as if it were the final product. What we didn’t expect (but what pleasantly surprised us) was that we were the only ones selected.

“Based on personal experience, I greatly appreciate the speed of delivery and the precise quality of processing complete orders at ONE3D. As part of our cooperation, as the only supplier in the Czech Republic, you produced 2K prototype parts for us in a very short time with the required quality.”

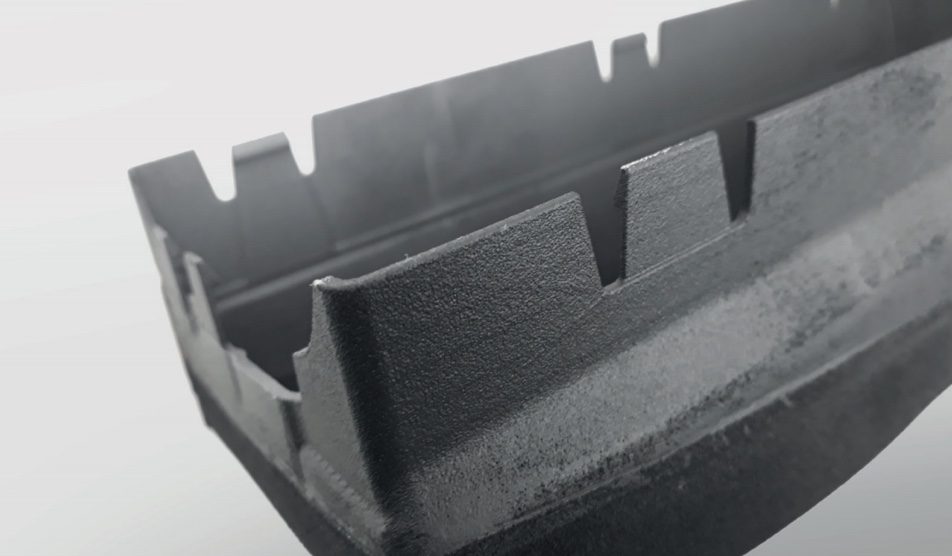

Bc. Luděk Štěpánek, Coordinator of Model and Surface Treatment Technology Detail of the final prototype

Detail of the final prototype

In the final phase, the client tested the part during assembly, during which the required properties were confirmed and, guided by our prototype, began mass production.

Rapido prototypo vehiculum

It sounds like an incantation, and when you see the creation of the prototype using additive technologies, it really looks like magic. A part materializes in front of you “out of nowhere” with properties that often can’t be achieved by any other process. Moreover, it’s fully functional, as if it just “rolled off the production line.”

But this air distribution part represents only the beginning of the possibilities of Rapid prototyping and additive manufacturing in the automotive sector. You can design and manufacture any part, from plastic interior elements or complete headlights, to steel wheels in the gearbox and aluminum engine block, to an entire full-scale model of the car.

At the same time, in most cases, this results in innovation. The result will be lighter, stronger, more flexible and more precise. It’s made on an industrial 3D printer that differs from the hobby version to such a degree that it can produce car bodies, rocket engines or houses.