Rapid development of digitalization calls for progress across all fields, and end-use part development is no exception. With the development of information technology and manufacturing technologies, new options unlock for design engineers. One way to meet extreme strength requirements, reduction of material, mass and modal properties as well as price is to use topology optimization.

What is topology optimization?

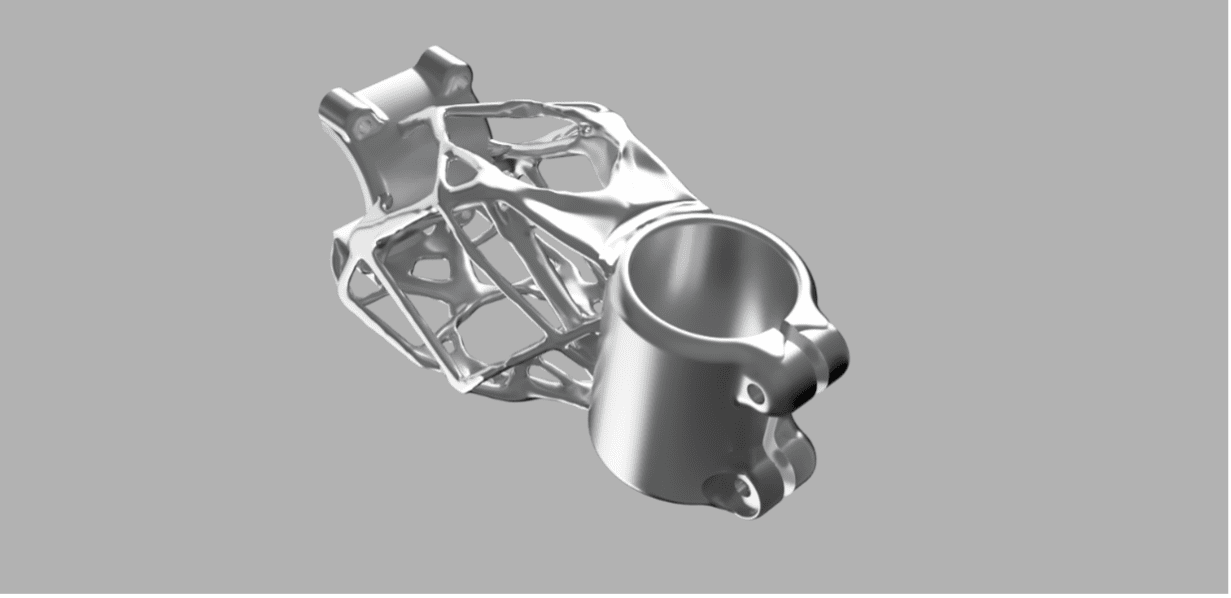

It is a method of optimization of shape, which uses computer algorithms to spread matter within a user-defined area according to given boundary conditions (bonds, acting forces and pressures, choice of material, limits of natural frequency, etc.). Topology optimization can maximize the effectiveness of a part by removing unnecessary matter from regions where no significant load transfer occurs. This can lead to extreme reduction of mass or solve problems with resonance and thermal stress.

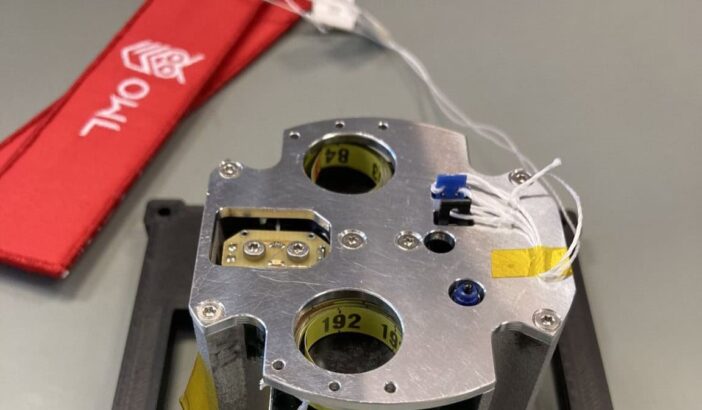

The result is often an organic shape, almost impossible to manufacture using conventional methods. This method of reduction of mass of the part is the ideal choice in combination with additive manufacturing, which can produce these intricate shapes without much problem and without increasing the cost.

Topology optimization vs. generative design

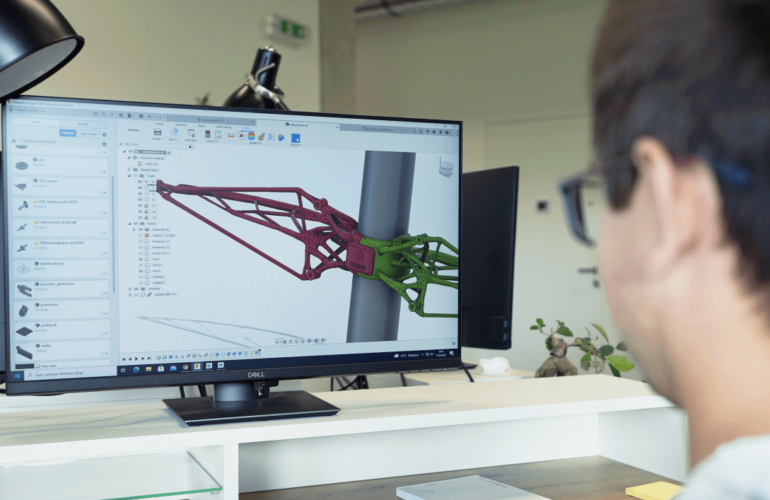

Topology optimization requires as its input an already designed part, which will then be optimized based on the boundary conditions and load. In other words, it requires the interaction of an experienced design engineer, which, however, limits the computer software.

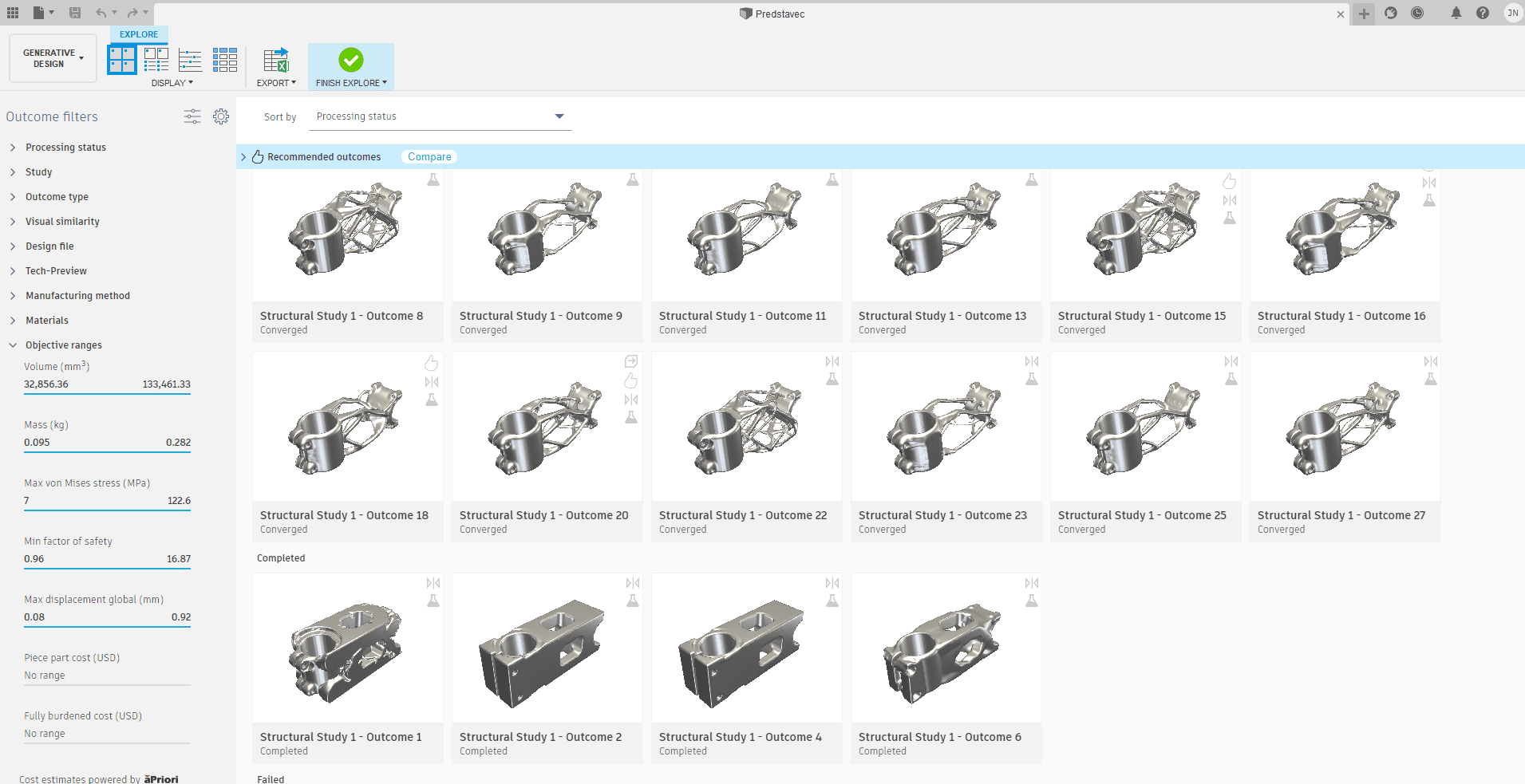

Generative design moves the idea of topology optimization yet a step further, by reducing the requirement of an initial shape of the part, partly replacing the role of a design engineer and thus saving them time. Output from certain software may be even a group of several variants at the same time, and it may support direct export into an editable model comprised of general areas.

Advantages of part optimization

Design engineers often require a sound reason to stray from classical design activities or time-tested production methods. Manufacturers have no reason to implement changes if the new design does not save resources, time, or cannot provide a better functionality.

Reduction of cost

Shapes with high topological complexity are often difficult to manufacture using conventional technologies, which can drastically increase production costs. Additive manufacturing eliminates this relationship between shape complexity and production costs.

Many times, optimized parts struggle to directly compete with production costs of the unoptimized, conventionally manufactured alternatives. It is important to realize, however, that design optimization can indirectly reduce production costs. For example:

- Fuel savings or extension of the lifetime as lowering mass also lowers energy requirements for moving the parts

- Mass and size reduction, leading to lower transportation costs

- Faster manual or robotic manipulation at the production line, thanks to reduced mass

Solving design problems

Topology optimization can solve not only problems with mass and cost, but also other design problems, for example:

- Reduction or elimination of vibration due to its optimized shape, leading to reduction of mechanical stress, wear and other unwanted effects caused by vibrations

- Design of extremely efficient cooler with respect to the construction site using shapes with complex surface topology

- Optimization of parts for aviation industry, which must be as light as possible, but which are also subjected to extreme forces, torques and temperatures.

With topology optimization, we can solve these problems and find the optimal balance between all of the required properties.

Saving time

Just like additive manufacturing can produce complex parts in rapid succession, topology optimization saves time for the design engineer, and it is able to create designs that would otherwise require the engineer to spend an immense amount of time to design, manufacture, test and adjust in the prototyping phase. While the computer software analyzes and optimizes the design, the design engineer can focus on other parts of the project.

Friendlier to the environment

Lower mass of a part means lower mass of a plane; lower mass of a plane means less fuel consumed. This is not just fuel savings, but also a lessening of the impact on the environment. Similarly for electric vehicles, lower mass means longer battery life. An optimized part combined with additive manufacturing will also produce less waste.

Applications of optimized parts

Aviation industry

The requirements of extreme lightening of aviation industry targeted parts is one of the most common applications of topology optimization. Each gram of reduced mass of an airplane is worth its weight in gold.

Automotive industry

In the automotive industry, there are two approaches to applying optimization. That is, maximum reduction of fuel consumption and maximum increase of power. They both try to find the right balance between mass and rigidity.