3D printing is often connected mainly with the production of prototypes. All you have to do is add the word “industrial” and suddenly the wheels of innovation start to grind.

Industrial 3D printing – or “additive manufacturing” – already has a great potential

for Czech companies too, and not just because of ASTM and ISO standards.

Additive manufacturing today enables production of end-use parts, parts to support production or the prototypes mentioned above. These parts are manufactured from plastics, metals, ceramics or even concrete. Some might be surprised that parts produced by additive manufacturing have useful properties comparable or even surpassing parts produced with conventional technologies.

Research of conventionally produced materials has been ongoing for almost 100 years. Materials and alloys are continuously improving. In the field of additive manufacturing, we could date the beginning of research to

somewhere in the 1980s. A full understanding of a single type of material usually takes 5–7 years. It is necessary to monitor the mechanical properties and understand the fatigue behavior as well as to search for new approaches to surface treatments.

However, changing the way of thinking about a product and development of a completely new design is the primary path to a completely new level of production. Additive thinking undoubtedly brings many advantages and savings, such as lowering mass while preserving mechanical characteristics. Another benefit is a reduction in the number of components in sets.

The technological difficulty of producing each single element is eliminated and we can manufacture even relatively complex and intricate sets as a single unit.

A very important element is the material itself, which makes research and development within this field absolutely essential. This can be seen in particular in manufacturing from metal materials. The microstructure is different

from classical conventional methods, such as casting. This leads to different mechanical behavior and it is necessary to pay special attention to fatigue behavior.

Thus it is essential to know the properties which the product is intended to achieve. Because industrial additive manufacturing is limited by material variety, research often focuses

on this field. Additive technologies support more than 20 metal materials.

Within plastic manufacturing it mostly involves polyamides or polypropylenes, materials

which can be easily utilized for end-parts. Technologies like FDM or SLA are often used for production of prototypes, where the functional requirements are not high. Science and research bring us insights into how individual materials behave when processed by different technologies and what their limits or strengths are.

Quality control is an inseparable component of the entire production chain. During the phase where powder is cleaned off the parts,

it is already possible to visually verify that production is proceeding correctly. Removing a part from the powder resembles an archeological dig.

Alchemy of heat treatment

After the part is manufactured, it is very important to apply post-processing. Some of the researched aspects are, for example, the impact of heat treatment on mechanical properties, electric or electromagnetic properties, thermal conductivity, etc. Thermal conductivity is an area that supports the necessity of researching heat treatment. Customers have the idea that aluminum or copper parts produced with additive manufacturing will have parameters suitable for heat conductivity applications. What is essential, however, is the heat treatment itself and a change of microstructural character, which leads to better thermal conductivity.

In the Czech Republic, a lot of inaccurate or dogmatic information about additive manufacturing is circulated. This stems from the current state of knowledge and disinterest in research. The situation abroad is different, though. Companies that invested in research and moved the field of additive research forward are further ahead in their understanding.

It is clear that the field of quality control will keep expanding. Customers have higher requirements

for the properties of printed parts, more or less comparable to parts produced by conventional manufacturing. Customers also expect the expansion of available materials, which is an area for research. We can see this, for example, in mold production or in the aviation industry. There will also be a constant improvement of properties of parts produced by additive manufacturing up to the level of conventional manufacturing

or even beyond it. Additive manufacturing itself will start to be regarded as a conventional method.

A programmable furnace for heat treatment with an inert argon atmosphere can be heated up to 1100 °C.

Temperature tolerance fluctuates between -6 to +6 °C, acc. to EN17052-1.

Breeding ground for development projects

We have realized that manufacturing based on industrial 3D printing does not mean just delivering a part, but also ensuring its quality. Unlike in other countries, this is a relatively young field in the Czech Republic. Customers often find it hard to believe information from suppliers and require the supplier to perform their own measurements and prove that their technology meets the required conditions.

During the development and design process of a new part intended for additive manufacturing, it is advantageous to keep manufacturability and material volume minimization in mind. The process of design is based

on optimizing algorithms, and the input for these calculations are experimentally discovered values of physical properties for specific materials manufactured on a specific device.

It is also necessary to verify production quality and to monitor whether the developments in the field of material processing meets the required conditions. The production chain consists of manufacturing, heat treatment, surface finishing and possibly machining. At each step, it is important to have information about the condition of the material, because all subsequent steps rely on it.

We began to refine the default settings of machines and optimize the process parameters

for given applications. For example, the production of thin walls requires the usage of different manufacturing parameters than standard parts.

Additive manufacturing with the SLS technology using the EOS P396 machine

We have solved these problems by establishing our own laboratory. It is now operating under the One3D lab brand, providing services for science and research related primarily to additive manufacturing, but also helping other companies in the field of product life cycle. It is also a kind of breeding ground for developmental projects implemented for customers. The laboratory enables monitoring of the manufacturing process and whether it, as well as the outputs, are still within the tolerance specified by the customer, whether the manufacturing conditions are met and whether the calibration of the machine tables is still valid. It helps with the development of a product and accelerates the time from development to entering the market.

One3D participates not just in R&D projects supported by Technological Agency of the Czech Republic and MPO, abut also implements direct commercial development and research.

One3D allows access to the laboratory technology to small and medium companies, which cannot afford these

– rather expensive – devices for their own workspace, or just do not want to buy them. Currently,

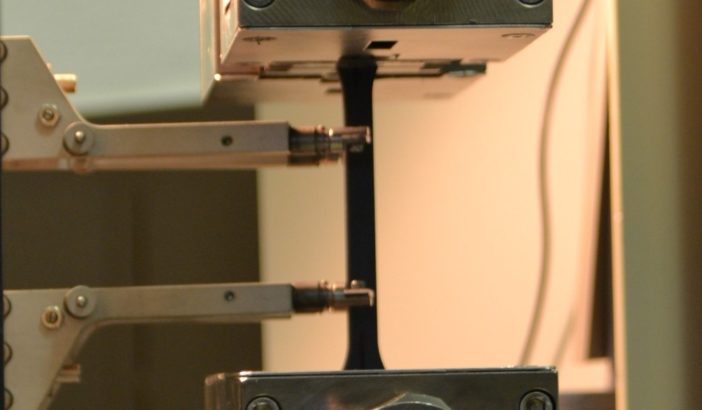

the laboratory is equipped with devices for analysis of dimensional accuracy and geometric tolerance (3D scanners), equipment for digital microscopy, for analysis of macro and micro structures and for identification of defects and material porosity. For sample preparation, it has a metallographic production line, which includes a saw, press and a grinder. For mechanical tests, the lab is equipped with a universal testing machine with power of 300 kN, which can be used for tensile, pressure or bending tests.

For 3D optical digitalization, we use the ATOS 5 scanner from leading German producer GOM/ZEISS.

Among the tools for mechanical testing, there is also a durometer, which can be used, for example, when planning the heat treatment of metal parts produced by additive manufacturing. Other laboratory tests are then implemented with our contracted partners.

This article was also published in the magazine Strojirenstvi.cz, the digital version of which is available at

3d-tisk.cz: