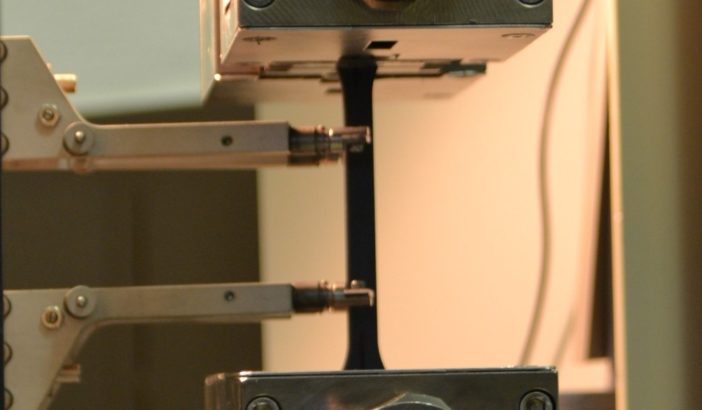

A new machine is reporting for duty. Early this August, 2019, we brought our new smoothing machine PostPro3D into operation. The PostPro3D is from Additive Manufacturing Technologies (AMT), a company that developed this innovative solution in cooperation with the university in Sheffield, England.

Complex system

PostPro3D enables precise part surface smoothing using vapors. This process provides treatment against liquid or gas ingress, reduces porosity and improves mechanical properties. It can also greatly enhance and brighten the hues of color-painted parts. Thanks to the certification of the process according to ISO 10993-5, ISO 10993-1 and ISO 10993-12, the smoothed parts are biocompatible and can be used for healthcare applications.

The automated process of the PostPro3D uses the BLAST (Boundary Layer Automated Smoothing Technology) technology for finishing, which is applicable to parts produced by various technologies (SLS, MFJ, FDM). Its advantage is the speed of the entire process; parts are smooth in less than an hour in its 600x400x400 mm large compartment. Our acquisition of the PostPro3D brings us and our clients a new and much more effective method of end-use part surface finishing.

Filip Mejvald, manager of the production team at One3D, adds:

“We are very grateful for our cooperation with AMT. They provided a professional approach from testing, through installation, up to excellent support during live operation. Operating the machine is easy and friendly and it delivers perfect results. It helps us, and our customers too, to advance the ideas of better functional parts further and further.”

ONE3D