Smoother surfaces for parts produced by additive manufacturing

Surface treatment of parts produced by additive manufacturing (3D printed) has a fundamental effect not just on the quality of surface itself, but on the mechanical properties of the part as well. The smoothing process is routinely used with almost any type of additive technology, including selective laser sintering (SLS) and (MJF). The basic method used by One3D is the chemical disruption of the surface in a pressure chamber, which not only reduces surface roughness, but also closes surface level capillaries. Among other things, smoothed parts receive new physical properties, like resistance to penetration of water or chemicals into the internal structure of the material. The smoothing process of polymers is partially automated, but still requires a certain level of experience and correct choice of parameters. Some of the main variables are the type of the geometry, wall thickness, number of parts in the chamber and others.

Fig. 1 Part after production (LEFT), part after smoothing (RIGHT)

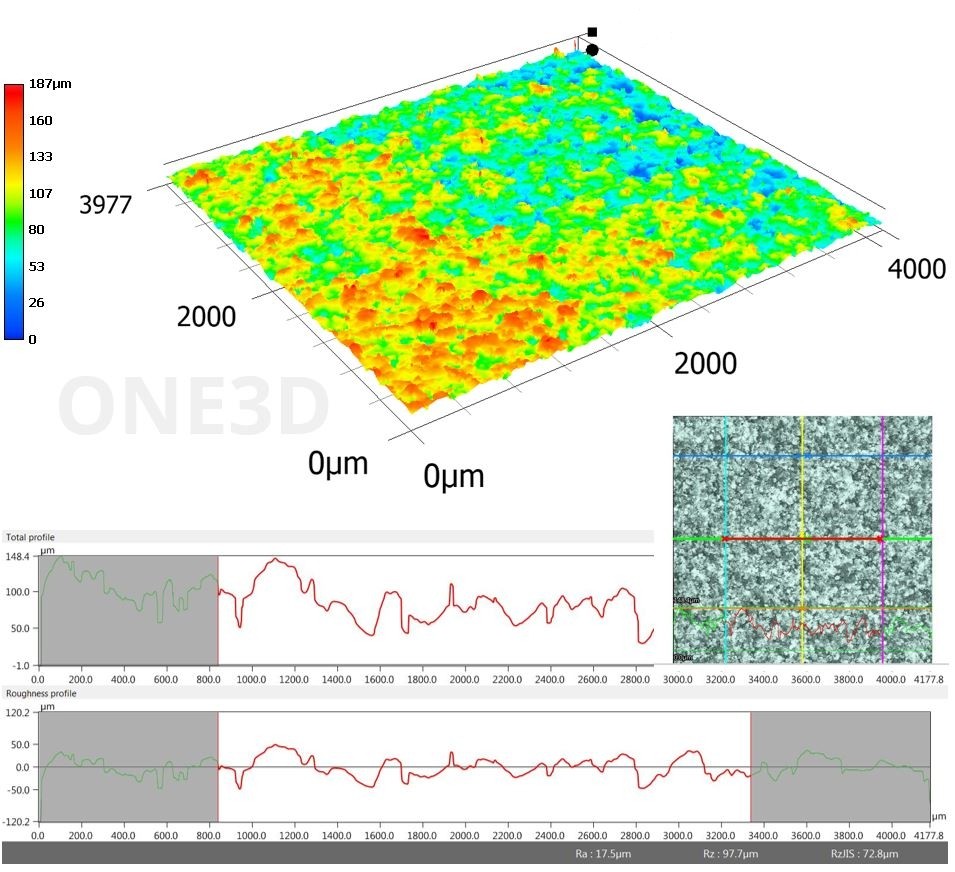

According to our measurements, this basic concept enables a reduction of surface roughness approximately by a factor of 3 (from Ra 17.5 to Ra 5.6 µm, see images). This has an impact on a range of other physical properties of the product. The most frequently used property describing surface roughness is the arithmetic mean deviation of roughness profile. Another frequently used value is the 10-point average surface roughness – Rz. In this case, the values are: Ra=17.5 µm and Rz=97.7 µm. With the smoothing process, the original Ra value can be reduced up to threefold.

Fig. 2 Surface structure after production, MJF

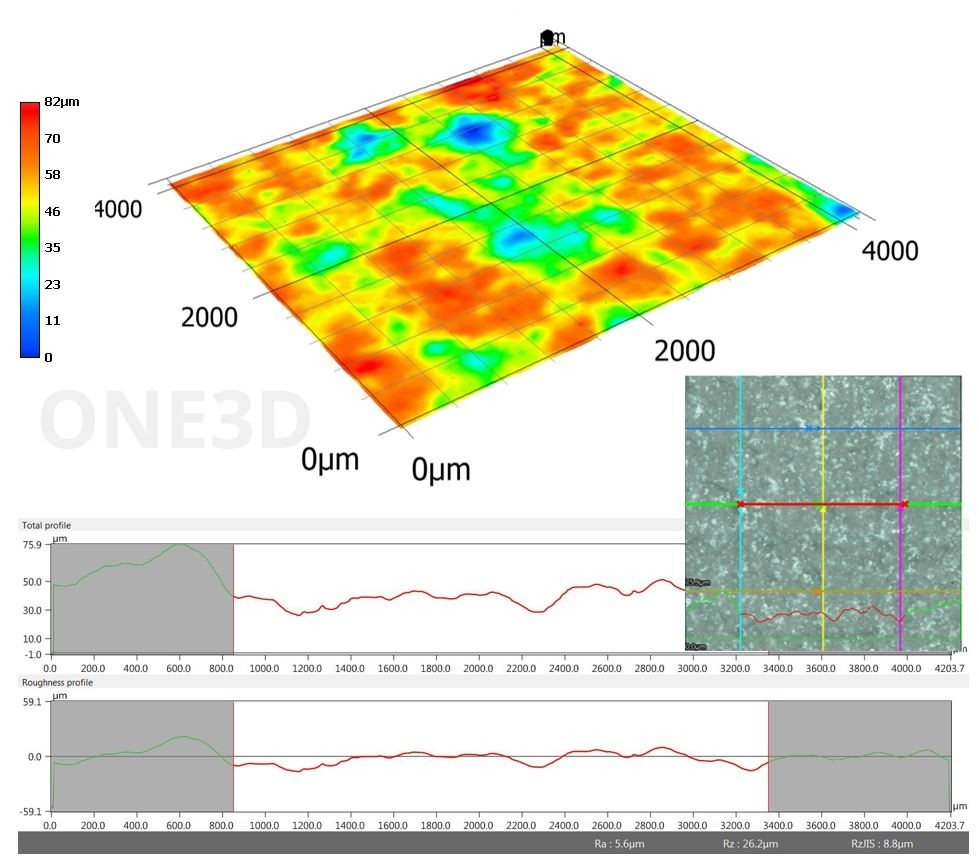

The image below shows the surface roughness analysis performed after the application of chemical smoothing. Ra=5.6 µm, Rz=26.2 µm. The value of Ra is the arithmetic mean deviation of roughness profile, Rz is the value of 10-point average surface unevenness. The first image shows a comparison of two states before and after smoothing. The difference is apparent at first glance. Digital microscope analysis shows a fundamental reduction of surface roughness.

Fig. 3 Surface structure after production with chemical smoothing

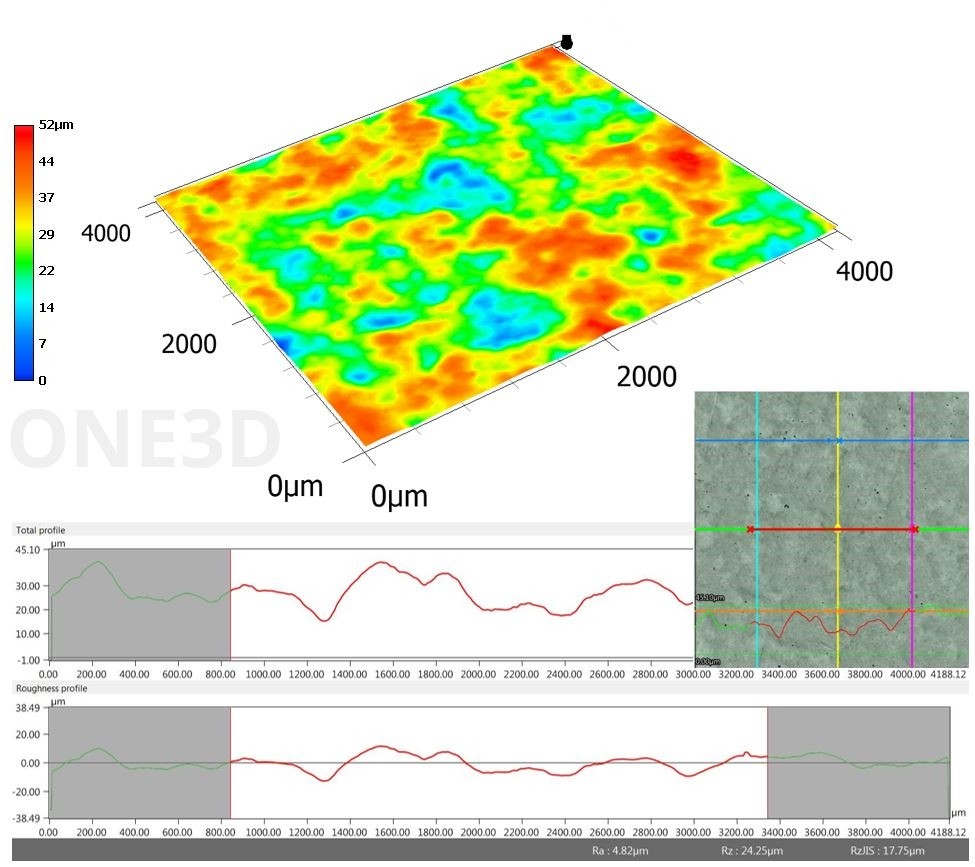

Parts prepared in this way can be processed further, e.g. plated. In the mounting line, the surface of a part is coated with a very fine metal film, e.g. aluminum. The goal of this process might be enhancement of electrostatic or ergonomic properties. After the plating process, the values of surface roughness are Ra=4.8 µm and Rz=24.25 µm.

Fig. 4 Surface structure after applying aluminum plating

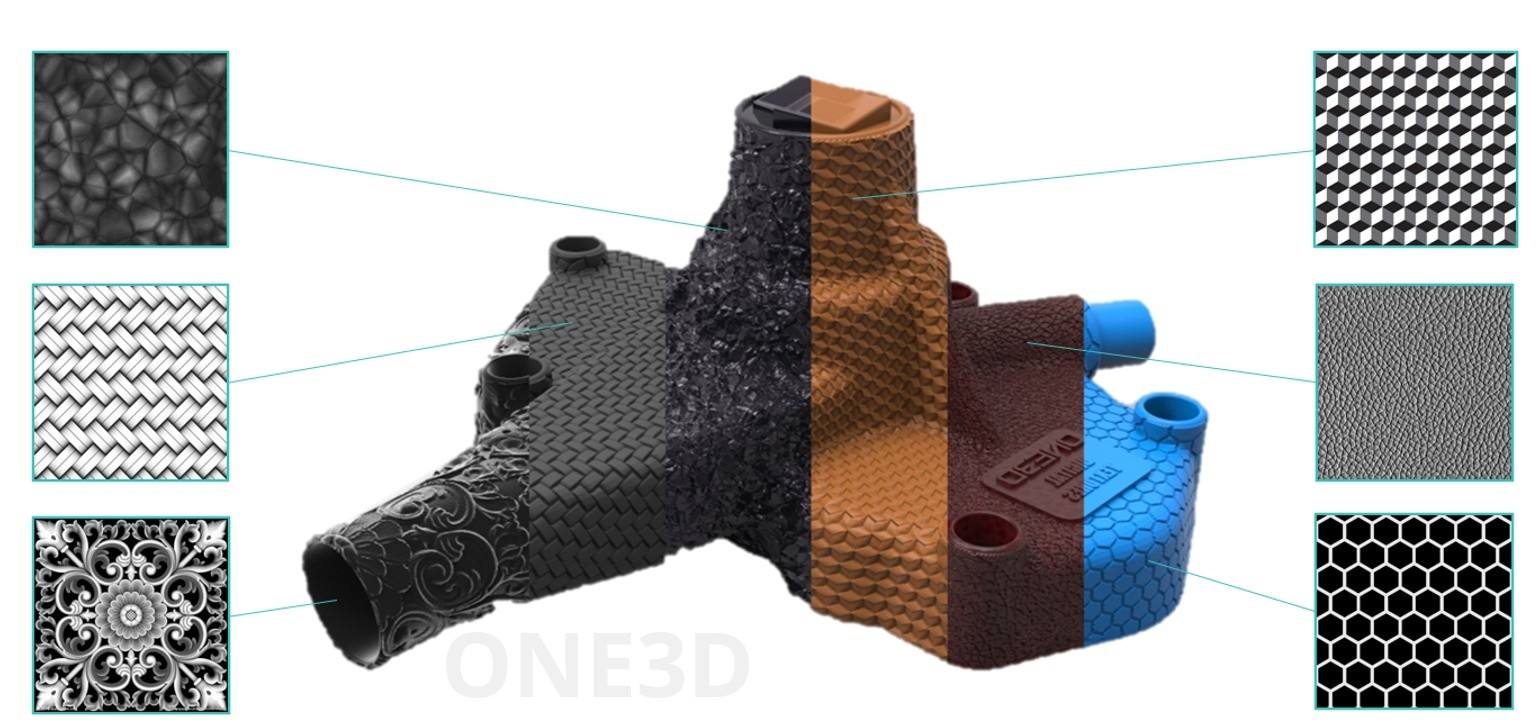

Dip dyeing and digital textures for end-use products

Another interesting property resulting from the smoothing process is colorfastness. Parts produced with the SLS or MJF technology can be painted with color, usually via dip dyeing. The advantage is that the color seeps under the surface of the part, typically tens of microns, and the part becomes resistant to visible defects, if mechanical damage occurs. One very attractive area of surface finishing is the so-called texturing. It is used to produce fine, detailed textures, like imitation leather, as part of the 3D printing process. After subsequent chemical smoothing, the surface appears very realistic. Surface texturing in combination with smoothing can then enhance even its ergonomic properties.